steel coil manufacturer colour coated steel coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC | Thickness: | 0.12~1.2mm |

| Place of Origin: | Shandong China (Mainland) | Brand Name: | CNBM | Model Number: | CGCC |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | Boiler Plate | Special Use: | Wear Resistant Steel | Width: | 600~1250mm |

| Length: | as your requirements | Color: | all RAL colors or customers samples color | Zinc coating: | 40-275g/m2 |

| Packaging: | Standard export seaworthy packing | Paint: | PE, PVDF, SMP, HDP | Coil weight: | 3-8mt |

| Coil ID: | 508mm,610mm | Payment: | 30% deposit, 70% by T/T against B/L copy; or by L/C | Back coating thickness: | 5-7um |

| Top coating thickness: | 20-25um | Product Name: | Prepainted galvanized steel |

Packaging & Delivery

| Packaging Detail: | Standard export packing, 4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal and waterproof paper wall protection disk, galvanized metal and waterproof paper around circumference and bore protection |

| Delivery Detail: | 25 Days after 30% deposit or L/C at sight |

Specifications

PPGI/Color Coated Steel Plates

Thickness: 0.12mm-1.2mm

Width: 600mm-1250mm

Length: customized

Grade:CGCC, DX51D

Product Description

PPGI Color Coated Steel Sheet in Coil

With the sophisticated equipment, you can get the best quality with most competitiveprice PPGI as below.

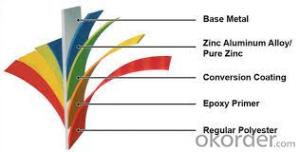

Detailed Product Description of prepainted steel coil

Our prepainted steel coil production line imported from America AB Corp and British CT Corp,it can be regarded as one of the most advanced unit in China. Our prepainted steel coil have outstanding formability,superb durability,good adhesion,wide availablity.Quick and reliable delivery for both small and large orders is our promise.

Our factory specialing in the export of the prepainted steel coil PPGI,Color coated steel coil,PPGI ,prepainted steel coil,color coated steel coil,stainless steel and other building materials.And our company trading here,exporting prepainted steel coil PPGI with good qulity and low price in China

Our factory prepainted steel coil production line in Tianjin in 2008,and many factories before 2010 have not yet been established,We have a proven technology,and we ensure quality

Painting

Category of Painting | Item | Code | |

Polyester | PE | ||

High-durability polyester | HDP | ||

Silicon modified polyesters | SMP | ||

Polyvinylidene fluoride | PVDF | ||

Easy-Cleaning | — | ||

Painting Thickness | Top side: 20+5microns; | ||

Bottom side: 5~7microns. | |||

Color System | Produce according to RAL Color System or as per buyer’s color sample. | ||

Painting structure | Top surface | Bottom surface | |

Primer coating | No coating | 1/0 | |

Primer coating | Primer coating | 1/1 | |

Primer coating + Finish coating | No coating | 2/0 | |

Primer coating + Finish coating | Primer coating or single back coating | 2/1 | |

Primer coating + Finish coating | Primer coating + Finish back coating | 2/2 | |

- Q: i have a question on a test and the questions before it are about blast furnace, wrought iron and cast iron...question 16 is..What is Steel?i dont really get what im being asked.. there could be many answers, what answer are they looking for?

- steel is a mixture of two or more metal or a metal with non metal to obtain both properties of the indivudual components. carbon steel for example.

- Q: How are steel coils packaged for transportation?

- Steel coils are commonly prepared for transportation through various methods in order to guarantee their secure and safe delivery. The packaging procedure consists of multiple steps that serve to shield the coils from harm during transit and facilitate their handling and loading onto trucks, ships, or trains. To begin with, steel coils are tightly wound and fastened using steel straps or bands to maintain their compactness and prevent unwinding. These straps are typically made from high-strength steel and securely fastened at regular intervals around the coil's circumference. This not only preserves the coil's shape but also prevents any movement while in transit. Following this, the coils are frequently positioned on wooden or steel pallets to establish a stable foundation and enable easy handling with forklifts or cranes. The pallets are usually tailored to fit the dimensions of the coils and designed to withstand the weight and stress of the loaded coils. In order to provide additional protection, steel coils are often enveloped in a layer of protective material such as plastic or paper to shield them from moisture, dust, and other potential contaminants. This wrapping also serves to prevent any scratching or damage to the coils' outer surface. Moreover, to ensure the coils remain secure and avoid shifting during transit, they are oftentimes housed within a steel or wooden crate. These crates offer an extra layer of protection and stability, particularly when transporting larger coils or multiple coils together. Lastly, once the coils are properly packaged, they are typically loaded onto flatbed trucks, shipping containers, or railway cars for transportation. During the loading process, great care is taken to ensure the coils are positioned securely and that weight distribution is balanced to prevent any potential damage or accidents while in transit. In conclusion, steel coils are packaged for transportation by securely binding them with steel straps, placing them on pallets, covering them with protective material, and, if necessary, enclosing them within crates. This packaging procedure serves to safeguard the coils and guarantee their secure and efficient transportation to their intended destination.

- Q: What are the challenges faced in the recycling of steel coils?

- The recycling of steel coils presents several challenges that must be overcome. To start, the collection and sorting process poses a significant hurdle. Steel coils are often utilized in large-scale industries and construction projects, making it challenging to gather and transport them for recycling purposes. Moreover, steel coils can become mixed with other materials, such as plastic or wood, further complicating the sorting process. Another obstacle is the size and weight of steel coils. Given that steel is a heavy material, handling and processing large coils can be quite difficult. Specialized equipment and machinery may be necessary to efficiently move and separate the coils, thereby increasing the cost and complexity of the recycling process. Additionally, the recyclability of steel coils can be impacted by varying quality. These coils may contain impurities or contaminants, such as oil or paint, that must be eliminated before recycling. Such impurities can compromise the integrity and quality of the recycled steel, making it less desirable for certain applications. Moreover, the recycling of steel coils demands substantial energy and resources. Melting down the steel requires a significant amount of energy, while the transportation and processing of the coils also consume resources and contribute to carbon emissions. Consequently, the environmental friendliness of the recycling process can be diminished. Lastly, the viability of the recycling industry can be influenced by fluctuating market demand for recycled steel coils. The demand for steel products can vary depending on economic conditions and industry trends, making it challenging for recyclers to find buyers for their recycled coils. This can potentially result in stockpiling or disposal difficulties. In conclusion, while recycling steel coils offers environmental benefits and resource conservation, several challenges must be addressed for its successful implementation. These challenges encompass collection and sorting, handling and processing, quality control, energy and resource consumption, as well as market demand.

- Q: What is the average lifespan of a steel coil storage rack?

- The average lifespan of a steel coil storage rack can vary depending on several factors such as the quality of the rack, proper maintenance, and usage conditions. However, with proper care and maintenance, a well-built steel coil storage rack can typically last anywhere from 10 to 20 years or even longer.

- Q: could anybody tell me the the weight of a cubic metre of mild steel? and where to get this info from?

- Weight per meter kg/m kg/m = (Oc - 4Wt) * Wt * 0.00785 Oc = outside circuit, Wt = wall thickness For sq. steel tubes: Oc = 4*a For rect. steel tubes: Oc = 2a + 2b Specific Weight =7.85 g/cm3

- Q: How are steel coils used in the manufacturing of industrial mixers?

- Steel coils are used in the manufacturing of industrial mixers as they provide a strong and durable structure for the mixer body. The coils are shaped and welded to create the necessary components, such as the mixing chamber and blade supports. This ensures that the mixer can withstand the high forces and vibrations involved in mixing large quantities of materials in industrial applications.

- Q: Can steel coils be coated with heat-resistant materials?

- Yes, steel coils can be coated with heat-resistant materials.

- Q: (I'm not sure if steel is in fact a mineral)But I want to know if .. Last say topaz is stronger/harder then steel

- Sandpaper , quartz will wear a hole in alloy steel. Just rub it. The steel that is.

- Q: How are steel coils used in the manufacturing of suspension arms?

- Steel coils are used in the manufacturing of suspension arms as they provide the necessary strength and flexibility required to absorb shocks and vibrations, ensuring a smooth and stable ride. The coils are typically placed around the suspension arm and compressed under the weight of the vehicle, allowing them to act as springs, supporting the weight of the vehicle and maintaining proper suspension alignment.

- Q: What industries use steel coils?

- Several industries use steel coils, including automotive, construction, manufacturing, and transportation. Steel coils are commonly used in the production of various metal parts, components, and structures due to their durability, strength, and versatility. They are utilized in manufacturing automobiles, appliances, pipes, roofing materials, and even in the construction of bridges and buildings. Additionally, steel coils are essential in the transportation industry for the fabrication of railcars, ships, and other heavy-duty vehicles.

Send your message to us

steel coil manufacturer colour coated steel coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords