Hot and Cold Rolled Steel Strip Coils with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Steel Strip Coils:

Steel strips is one of our main products that is widely used in making band saw blade & other blades to cut paper, weed, etc.

Festures of Steel Strip Coils:

1. Each coil is closely covered by oil paper or plastic film.

2. Outside it is firmly packed with sack cloth or compound paper.

3. Steel strap or PP strap to pack the outside to ensure safety.

Specifications of Steel Strip Coils:

1:Chemical industry equipment, Industrial tanks

2:Medical Instruments,Tableware, Kitchen utensil, kitchen ware

3:Architectural purpose, Milk & Food processing facilities

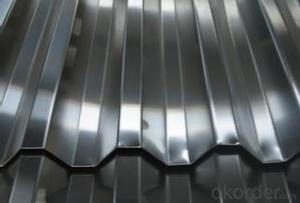

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: How do steel strips contribute to dimensional stability in various applications?

- The inherent properties and characteristics of steel strips play a crucial role in maintaining dimensional stability in various applications. To begin with, steel strips are renowned for their exceptional strength and rigidity. This unique quality enables them to withstand external forces and resist deformation, ensuring that the dimensions of the application remain stable. Whether it be in construction, automotive, or manufacturing industries, steel strips provide the necessary structural integrity to prevent any significant changes in shape or size. Furthermore, steel strips exhibit excellent thermal stability. They possess the ability to withstand extreme temperature variations without experiencing significant expansion or contraction. This characteristic proves particularly vital in applications where dimensional stability is of utmost importance, such as in the aerospace industry or precision engineering. Steel strips can retain their shape and size even under extreme temperature conditions, thus guaranteeing the accuracy and reliability of the final product. In addition, steel strips demonstrate minimal creep, which refers to the gradual deformation under a constant load over time. This property is particularly valuable in applications that demand long-term dimensional stability, such as bridges or infrastructure projects. Steel strips can endure prolonged stress without experiencing significant deformation, thereby ensuring that the dimensions of the structure remain stable over time. Moreover, steel strips possess exceptional corrosion resistance, which is essential for applications exposed to harsh environments or corrosive substances. By preventing corrosion, steel strips retain their original dimensions and structural integrity, thus contributing to dimensional stability. Finally, steel strips can be precisely manufactured to meet specific dimensional requirements. They can be produced with tight tolerances and accurate dimensions, guaranteeing consistency and stability across various applications. This precision in manufacturing allows for seamless integration and assembly, minimizing any potential dimensional variations. In conclusion, steel strips play a vital role in achieving and maintaining dimensional stability in various applications due to their high strength, thermal stability, resistance to creep and corrosion, and precise manufacturing capabilities. These properties ensure that the dimensions of the application remain stable, reliable, and consistent over time, providing durability and functionality to the end product.

- Q: Can steel strips be used in electrical enclosures?

- Yes, steel strips can be used in electrical enclosures. Steel strips are commonly used in the construction of electrical enclosures due to their durability, strength, and ability to provide protection against external elements. They help to secure and reinforce the enclosure, ensuring the safety and integrity of the electrical components within.

- Q: How are steel strips polished for aesthetic purposes?

- Steel strips can be polished for aesthetic purposes through a multi-step process that involves various techniques. The first step is to clean the steel strip thoroughly, removing any dirt, grease, or other contaminants. This can be done by using a solvent or a degreaser. Next, the strip is sanded using progressively finer grits of sandpaper or abrasive pads. This helps to remove any surface imperfections, scratches, or rough spots. The goal is to create a smooth and even surface. After sanding, the strip goes through a buffing process. Buffing involves using a rotating wheel or a polishing machine with a soft cloth or a buffing pad. The wheel or pad is coated with a polishing compound, which can be a paste, liquid, or powder. This compound helps to remove any remaining scratches and brings out a shine on the steel strip. Depending on the desired level of polish, multiple buffing stages may be required, using different compounds with varying levels of abrasive properties. The process may involve using different types of wheels or pads, each designed for specific polishing requirements. Once the desired level of polish is achieved, the strip is thoroughly cleaned again to remove any residue from the polishing compounds. This ensures a clean and smooth finish. Finally, the strip may undergo additional treatments, such as electroplating or coating, to enhance its aesthetic appeal and provide protection against corrosion. Overall, the process of polishing steel strips for aesthetic purposes involves a combination of cleaning, sanding, buffing, and finishing to create a smooth, shiny, and visually appealing surface.

- Q: How are steel strips processed further for specific applications?

- Various techniques and methods are utilized to further process steel strips for specific applications. Cold rolling is a commonly used method where the strips are passed through a series of rollers at room temperature to reduce thickness and enhance surface finish. This procedure also improves the mechanical properties of the steel, including strength and hardness. After cold rolling, steel strips can undergo annealing, which involves heating them to high temperatures and gradually cooling them. This helps to alleviate internal stresses, enhance ductility, and refine the grain structure of the steel, resulting in better suitability for specific applications. Coating is another essential step in steel strip processing. Depending on the intended use, the strips can be coated with materials such as zinc, aluminum, or polymer to provide protection against corrosion, improve aesthetics, and enhance performance in specific environments. Furthermore, steel strips can be subjected to various forming processes, such as bending, stamping, or deep drawing, to shape them into specific components or products. These forming techniques enable the transformation of steel strips into a wide range of applications, including automotive parts, construction materials, electrical appliances, and packaging materials. Additionally, secondary operations such as slitting, edging, and shearing may be conducted to further refine the dimensions and characteristics of the steel strips for specific applications. These secondary processes aid in achieving the desired size, shape, and surface quality required by different industries. In conclusion, steel strips undergo further processing through cold rolling, annealing, coating, forming, and secondary operations to customize their properties and dimensions for specific applications. These processing techniques are crucial in optimizing the performance, functionality, and versatility of steel strips in various industries.

- Q: What are the dimensions of steel strips?

- The dimensions of steel strips can vary depending on their intended use and manufacturing process. Generally, steel strips are thin, flat pieces of steel that have a rectangular shape. They typically have a length that is much greater than their width, and their thickness can range from a few millimeters to a few centimeters. The width of steel strips can vary widely, ranging from a few millimeters to several meters. Additionally, steel strips may come in various standard sizes or be custom-made to meet specific requirements. Therefore, it is important to consult the specific standards or specifications for the desired steel strip to determine its exact dimensions.

- Q: Can steel strips be used for making springs?

- Yes, steel strips can be used for making springs.

- Q: What are the measuring techniques for steel strips?

- Steel strips can be measured using various techniques. One commonly used method involves calipers, which are handheld devices that can determine the strip's thickness, width, and length. Calipers are known for their accuracy and user-friendliness. Alternatively, micrometers can be employed for more precise measurements, particularly for thinner steel strips. Micrometers offer greater accuracy in measuring thickness. Laser sensors are another option for measuring steel strip dimensions. These sensors utilize laser beams to scan the strip and provide precise measurements of its thickness, width, and length. Overall, these measuring techniques play a crucial role in ensuring the quality and precision of steel strips in diverse industries, including manufacturing, construction, and automotive.

- Q: How are steel strips used in automotive manufacturing?

- Steel strips are used in automotive manufacturing for various applications such as body panels, structural components, chassis parts, and reinforcements. They provide high strength, durability, and formability, making them ideal materials for creating safe and robust vehicles. Steel strips are often used in stamping and forming processes, where they are shaped and molded into specific parts and components that enhance the overall performance and safety of automobiles.

- Q: 1 can thick galvanized steel square pipe burn welding?

- Galvanized square is a hot-rolled or cold-rolled galvanized steel or galvanized sheet for the blank shape by the cold bending process after section steel pipe welded square hollow square cross-section shape and size of the high-frequency; or the cold hollow steel well in advance of the re galvanized square by galvanizing processing of pipe.

- Q: What is the hardness of a steel strip?

- The hardness of a steel strip refers to its ability to resist deformation or indentation. It is commonly measured using scales such as the Rockwell Hardness Scale or the Brinell Hardness Scale. The specific hardness of a steel strip can vary depending on factors such as its composition, heat treatment, and manufacturing process. Steel strips with a higher hardness are typically more resistant to wear and can withstand higher loads, making them suitable for applications that require durability and strength, such as in automotive components, tools, or machinery parts.

Send your message to us

Hot and Cold Rolled Steel Strip Coils with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords