Stainless Steel Coil Cold Rolled 304 With High Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Coil Cold Rolled 304 With Good Quality

1.Structure of Stainless Steel Coil Cold Rolled 304 With Good Quality

Cold Rolled stainless steel Coil with good quality is one of the raw material of the cold rolled stainless steel Coil, which can be used

directly in many places. Stainless Steel (Stainless Steel) is short for acidproof Stainless Steel, resistant to weak corrosive medium

such as air, steam, water, or with a Stainless Steel grade.

2.Main Features of Prefabricated Steel Structure High Building Project

The purpose of the different requirement for welding performance are different.1 Kind of tableware generally do not require the performance

of welding, even including some pot class enterprise. But the vast majority of products all need raw materials welding performance is good,

like the 2 kinds of tableware, thermos flask, steel pipes, water heaters, water dispensers, etc.

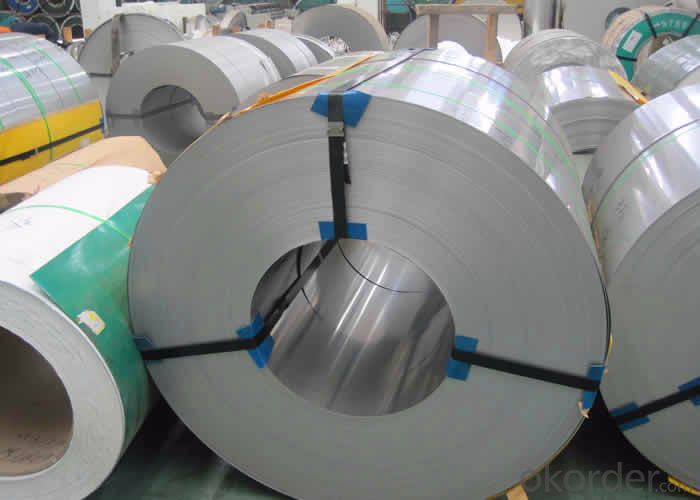

3. Stainless Steel Coil Cold Rolled 304 With Good Quality Images

4. Stainless Steel Coil Cold Rolled 304 With Good Quality Specification

Austenitic stainless steel The title Chromium is more than 18%, still contain about 8% of the nickel and small amounts of molybdenum,

titanium, nitrogen and other elements. Good comprehensive performance, corrosion resistant to a variety of media. Number of austenitic

stainless steel is commonly used one cr18ni9, 0 cr19ni9, etc. In the Wc < 0.08% 0 cr19ni9 steel, steel grade is marked as "0". This class

contains large amounts of Ni and Cr in steel, make steel in austenitic state at room temperature. This kind of steel has good plasticity

and toughness, weldability and corrosion resistance and nonmagnetic or weak magnetic, the corrosion resistance in oxidizing and reducing

medium are good, used to make acid equipment, such as corrosion resistant containers and equipment lining, pipelines, nitric acid

resistant equipment parts, etc., also can be used as the main body of watches and clocks jewelry stainless steel material. Austenitic

stainless steel with solid solution treatment, the steel heating to 1050 ~ 1150 ℃, then water-cooled or air-cooled, for single-

phase austenitic organization.

5. Applications of Stainless Steel Coil 304 With Good Quality

1. Kitchenware: tableware, cookware, Stoves…

2. Food packing: storage cans, food containers…

3. Construction: bridge, roofing, wall, decoration, bathroom accessories…

4. Precision instruments: electrical products, aerospace…

5. Others: automotive parts, machine building, chemical processing, farming…

6.FAQ of Stainless Steel Coil 304 With Good Quality

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory.

Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM

casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict

quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary

follow-up service assurance.

③How is the packaging and delivery?

Standard export packing (Coil: waterproof paper + protective steel ring; Circle: wooden box), or as your requirement and the delivery term

is based on the project.

④How long can we receive the product after purchase?

In the purchase of product within 20 working days, We will arrange the factory delivery as soon as possible. The specific time of receiving

is related to the state and position of customers. Commonly 20 to 40 working days can be served.

- Q: Are stainless steel strips magnetic?

- Yes, stainless steel strips can be magnetic or non-magnetic, depending on the specific type of stainless steel used. Stainless steel is an alloy that contains iron, which is inherently magnetic. However, the addition of certain elements such as nickel or manganese can alter the magnetic properties of stainless steel. Stainless steel strips that have a higher nickel content, such as the popular 304 or 316 grades, are generally non-magnetic. On the other hand, stainless steel strips with lower nickel content, such as the 400 series, can be magnetic. Therefore, it is important to consider the specific grade and composition of the stainless steel strip when determining its magnetic properties.

- Q: Can stainless steel strips be used in contact with food?

- Stainless steel strips, indeed, find utility when they come into contact with food. Owing to its non-reactive characteristics, corrosion resilience, and sturdy build, stainless steel stands as a favored option for food-related purposes. It refrains from releasing any detrimental substances into the food and wards off staining, thereby ensuring a secure and sanitary material for food handling, storage, and presentation. Frequently, stainless steel strips find employment in commercial kitchens, food processing facilities, as well as household appliances like refrigerators, sinks, and cookware.

- Q: Can stainless steel strips be used in high-pressure applications?

- Stainless steel strips have the capability to be employed in high-pressure scenarios. The reputation of stainless steel resides in its remarkable resistance to corrosion and its strength, rendering it a fitting material for a multitude of industrial uses, particularly in environments with high pressures. In the creation of pressure vessels, pipes, valves, and other exposed components, stainless steel strips are frequently utilized. The material's capacity to endure heightened pressures, in conjunction with its resistance to corrosion and oxidation, establishes stainless steel strips as an unfailing choice for high-pressure applications. Moreover, the heat resistance and durability of stainless steel further enhance its adaptability for deployment in such challenging conditions.

- Q: Can 111 stainless steel strips be laser cut for precise shapes?

- Yes, 111 stainless steel strips can be laser cut for precise shapes.

- Q: Are stainless steel strips resistant to stress corrosion cracking?

- Yes, stainless steel strips are generally resistant to stress corrosion cracking due to their high levels of chromium and nickel content, which form a protective oxide layer on the surface, preventing the penetration of corrosive agents.

- Q: What industries commonly use stainless steel strips?

- Stainless steel strips possess exceptional properties and versatility, making them widely utilized in various industries. One industry that frequently employs stainless steel strips is the automotive sector. These strips are utilized to manufacture a range of automotive components, including exhaust systems, trim, and decorative elements, thanks to their corrosion resistance, strength, and attractive appearance. The construction industry is another sector that extensively relies on stainless steel strips. These strips are employed in the construction of infrastructure such as bridges, tunnels, and buildings due to their excellent structural integrity, durability, and resistance to environmental factors. Additionally, stainless steel strips find application in roofing, siding, and cladding. The food processing and packaging industry heavily depends on stainless steel strips as well. These strips are preferred for their hygienic properties, including easy cleaning, resistance to bacterial growth, and non-reactivity with food products. Consequently, stainless steel strips are used in the production of equipment like conveyors, mixers, and food storage containers. Moreover, the medical and pharmaceutical industries heavily rely on stainless steel strips for their equipment and instruments. Stainless steel's biocompatibility, corrosion resistance, and ease of sterilization make it an ideal choice for surgical tools, dental instruments, medical implants, and pharmaceutical manufacturing equipment. Additional industries commonly utilizing stainless steel strips include the aerospace sector, where they are employed in aircraft components, and the energy industry, where they find application in power plants, oil and gas processing, and renewable energy systems. In conclusion, the extensive range of properties offered by stainless steel strips has made them a popular and versatile choice across various industries. Their benefits encompass durability, corrosion resistance, hygiene, and strength, among others.

- Q: Are 111 stainless steel strips resistant to pitting and crevice corrosion?

- Yes, 111 stainless steel strips are resistant to pitting and crevice corrosion.

- Q: Can stainless steel strips be used in power generation plants?

- Yes, stainless steel strips can be used in power generation plants. Stainless steel is a versatile and highly durable material that is resistant to corrosion, heat, and pressure, making it ideal for various applications in power generation plants. One common use of stainless steel strips in power plants is for the fabrication of heat exchangers. These devices are crucial for transferring heat from one medium to another, such as converting steam into electricity. Stainless steel's resistance to corrosion and high-temperature environments makes it an excellent choice for heat exchanger tubes, ensuring their longevity and efficiency. Stainless steel strips are also utilized in the construction of various components in power plants, including valves, pumps, and piping systems. The material's strength, resistance to corrosion, and ability to withstand high-pressure environments make it suitable for these critical applications. Furthermore, stainless steel strips are often used in the manufacturing of turbine blades and other parts in steam and gas turbines. These components are exposed to extreme temperatures and high mechanical stresses, and stainless steel's ability to retain its strength and shape under such conditions makes it a reliable choice. In addition to its physical properties, stainless steel is also favored in power generation plants due to its hygienic properties. It is easy to clean and maintain, ensuring that the equipment remains free from contaminants and does not compromise the plant's operations. In conclusion, stainless steel strips are commonly used in power generation plants due to their corrosion resistance, high-temperature tolerance, strength, and hygienic properties. From heat exchangers to turbine components, stainless steel is a versatile material that contributes to the efficiency and reliability of power generation processes.

- Q: Can stainless steel strips be used for magnetic applications?

- Yes, stainless steel strips can be used for magnetic applications. However, it is important to note that stainless steel itself is not a magnetic material. The magnetic properties of stainless steel strips are typically achieved by adding other elements such as nickel or manganese to the alloy. These elements help to create a magnetic structure within the stainless steel, allowing it to be attracted to magnets. It is also worth mentioning that the magnetic strength of stainless steel strips may vary depending on the specific composition of the alloy.

- Q: Can stainless steel strips be used in the production of jewelry findings?

- Indeed, the utilization of stainless steel strips is viable when manufacturing jewelry findings. The endurance and resistance to corrosion exhibited by stainless steel render it a highly favored option for crafting jewelry findings. In fact, stainless steel is frequently employed in the creation of clasps, jump rings, earring hooks, and bead caps, among other components. The malleability of stainless steel strips enables them to be conveniently molded, cut, and fashioned into diverse jewelry findings, thus rendering them suitable for an extensive array of designs. Moreover, the sleek and contemporary aesthetic of stainless steel contributes to its desirability as a sought-after material in contemporary jewelry.

Send your message to us

Stainless Steel Coil Cold Rolled 304 With High Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords