Hot and Cold Rolled Steel Strip Coils with High Quality in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 122 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Steel Strip Coils:

Steel strips is one of our main products that is widely used in making band saw blade & other blades to cut paper, weed, etc.

Festures of Steel Strip Coils:

1. Each coil is closely covered by oil paper or plastic film.

2. Outside it is firmly packed with sack cloth or compound paper.

3. Steel strap or PP strap to pack the outside to ensure safety.

Specifications of Steel Strip Coils:

Our Products are packed and labeled according to rigorous internal regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product and quality information.

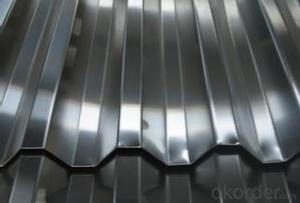

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: How are steel strips used in the production of tools?

- Steel strips are an essential component in the production of tools due to their high strength, durability, and versatility. These strips are primarily used in the manufacturing process to create various types of cutting tools, such as saw blades, drill bits, and knives. One of the main applications of steel strips in tool production is as the raw material for the tool's cutting edge. The strips are carefully shaped and sharpened to create a precise cutting surface that can effectively cut through different materials. The hardness and toughness of steel strips make them ideal for this purpose, as they can withstand the high forces and pressures exerted during the cutting process without deforming or breaking. Additionally, steel strips are used in the production of tool components that require high strength and rigidity. For example, they are commonly used in the construction of tool handles or frames, providing the necessary strength and stability for the tool to be used effectively. Due to their malleability, the strips can be easily shaped or bent to fit the desired design and ensure an ergonomic grip for the user. Moreover, steel strips are often used in the production of specialty tools, such as measuring instruments or precision engineering tools. These tools require high precision and accuracy, and steel strips can be precisely machined and calibrated to meet these requirements. The dimensional stability and uniformity of steel strips make them suitable for creating tools with consistent and reliable performance. In conclusion, steel strips play a crucial role in the production of tools by providing the necessary strength, durability, and versatility required by various cutting tools and tool components. The use of steel strips ensures the production of tools that are robust, reliable, and capable of performing a wide range of tasks in different industries and applications.

- Q: How do steel strips contribute to product sustainability in various applications?

- Steel strips contribute to product sustainability in various applications in several ways. Firstly, steel strips are highly durable and have a long lifespan. This means that products made using steel strips, such as automotive components, construction materials, and packaging, will have a longer service life, reducing the need for replacements or repairs. This durability not only reduces waste but also conserves resources that would have been used in manufacturing new products. Secondly, steel strips are recyclable. At the end of their life cycle, steel strips can be easily and efficiently recycled to create new products. This reduces the demand for new raw materials and minimizes the environmental impact associated with mining and extracting these materials. Recycling steel also requires less energy compared to producing steel from virgin materials, resulting in a significant reduction in greenhouse gas emissions. Furthermore, steel strips are highly versatile and can be used in a wide range of applications. This versatility allows for the creation of multiple products from a single steel strip, reducing the need for different materials. This not only simplifies the manufacturing process but also reduces waste and resource consumption. Moreover, steel strips have excellent strength-to-weight ratios. This means that products made using steel strips can be designed to be lightweight without compromising on strength and performance. For example, in the automotive industry, lightweight steel strips are used to manufacture fuel-efficient vehicles that consume less energy and emit fewer greenhouse gases. Lastly, steel strips have a high resistance to corrosion and wear, making them suitable for applications in harsh environments. This resistance ensures that products made using steel strips will have a longer lifespan, reducing the need for replacements and conserving resources. In conclusion, steel strips contribute to product sustainability in various applications by providing durability, recyclability, versatility, lightweight design options, and resistance to corrosion and wear. These qualities not only reduce waste and conserve resources but also help in minimizing the environmental impact associated with the manufacturing and disposal of products.

- Q: What are the main factors affecting the creep resistance of steel strips?

- The main factors affecting the creep resistance of steel strips are temperature, applied stress, and microstructure. Higher temperatures and higher levels of applied stress accelerate creep, while a finer and more uniform microstructure can improve creep resistance. Additionally, the presence of impurities and alloying elements can also influence the creep behavior of steel strips.

- Q: What are the common defects in steel strips?

- Some common defects in steel strips include surface defects such as scratches, pits, and scale formation, as well as edge defects like burrs and cracks. Other defects may include thickness variations, waviness, and non-uniformity in width.

- Q: Can steel strips be used in aerospace applications?

- Yes, steel strips can be used in aerospace applications. They are often utilized in various components such as brackets, supports, and fasteners due to their strength, durability, and resistance to high temperatures. However, the specific use and requirements of the aerospace application must be considered to ensure that the steel strips meet the necessary specifications and standards.

- Q: Can steel strips be used in the production of heat exchangers?

- Yes, steel strips can be used in the production of heat exchangers. Steel is a commonly used material in heat exchanger manufacturing due to its excellent thermal conductivity, high strength, and durability. Steel strips can be shaped and formed into the necessary components of a heat exchanger, such as fins, tubes, or plates. These components are crucial for efficient heat transfer between fluids in a heat exchanger. Steel strips also offer corrosion resistance, making them suitable for various environments and applications. Overall, steel strips are a viable and commonly used material for the production of heat exchangers.

- Q: How do steel strips resist corrosion?

- The process of corrosion resistance allows steel strips to withstand corrosion. This process involves various factors, including the composition of the steel, the presence of a protective coating, and the utilization of corrosion inhibitors. To begin with, the composition of steel strips plays a crucial role in their ability to resist corrosion. Steel contains iron as its primary component, along with small amounts of carbon, chromium, nickel, and manganese. These elements contribute to the formation of a protective oxide layer on the steel's surface. This layer acts as a barrier against corrosive substances. Additionally, steel strips are often coated with a protective layer to enhance their resistance to corrosion. Common coatings include zinc, which creates a protective barrier between the steel and the environment. In addition, paints or epoxy coatings are used to provide an extra layer of protection. These coatings not only prevent direct contact between the steel and corrosive substances but also act as a barrier against moisture, oxygen, and other corrosive agents. Furthermore, corrosion inhibitors are frequently employed to further enhance the resistance of steel strips. These inhibitors are chemical compounds added to the surrounding environment of the steel to reduce the corrosion rate. They work by forming a protective film on the steel surface or by altering the chemical properties of the environment to make it less corrosive. Examples of corrosion inhibitors include chromates, phosphates, and organic compounds. In conclusion, the corrosion resistance of steel strips is achieved through a combination of factors, such as the steel's composition, the presence of protective coatings, and the utilization of corrosion inhibitors. These measures work together to prevent the deterioration of the steel's surface, ensuring its durability and longevity.

- Q: Are steel strips used in the production of automotive chassis components?

- Yes, steel strips are commonly used in the production of automotive chassis components. Steel strips are preferred due to their high strength and durability, making them suitable for supporting the weight of the vehicle and providing structural integrity. These strips can be formed and welded into various shapes and sizes to meet the specific requirements of different chassis components, such as frame rails, cross members, and suspension mounting points. Steel strips also offer excellent corrosion resistance, reducing the risk of rusting and extending the lifespan of the chassis components. Additionally, steel strips are cost-effective and readily available, making them a popular choice in the automotive industry for chassis production.

- Q: How are steel strips protected against rust and corrosion?

- There are various methods to protect steel strips from rust and corrosion. One way is to apply a protective coating on the surface of the steel. This can be achieved through processes like galvanizing or painting. Galvanizing involves coating the steel with a layer of zinc, which acts as a sacrificial layer. Zinc is more reactive than steel, so it corrodes first and shields the steel beneath. This technique is highly effective, particularly in outdoor or high-humidity environments. Another commonly used method is painting. A layer of paint creates a barrier between the steel and the surrounding environment, preventing direct contact with moisture and oxygen. The paint can be formulated with additives that resist corrosion, providing even greater protection. In addition to coatings, corrosion inhibitors can also be used to safeguard steel strips. These are chemical compounds applied to the steel surface, forming a protective layer. Corrosion inhibitors work by either passivating the steel surface, reducing its reactivity, or by creating a film that prevents the penetration of corrosive substances. Proper storage and handling of steel strips are crucial in preventing rust and corrosion. This involves keeping the strips in a dry environment, away from moisture and corrosive substances. Regular cleaning and maintenance, such as removing any dirt or debris on the surface, also contribute to prolonging the steel's lifespan and preventing corrosion. In summary, a combination of protective coatings, corrosion inhibitors, and proper storage practices is vital to ensure the long-term protection of steel strips against rust and corrosion.

- Q: How are steel strips processed for surface coating?

- Steel strips are processed for surface coating through a series of steps that ensure proper adhesion and durability of the coating. The process typically involves cleaning, pre-treatment, and application of the coating. Firstly, the steel strips are thoroughly cleaned to remove any dirt, grease, or other contaminants that may hinder adhesion. This is usually done through a combination of mechanical cleaning, such as brushing or blasting, and chemical cleaning using solvents or alkaline cleaners. After cleaning, the steel strips undergo pre-treatment to improve the bonding between the surface and the coating. This can involve various methods such as phosphating, chromating, or zirconium-based treatments. These treatments create a thin layer on the surface that enhances adhesion and corrosion resistance. Once the pre-treatment is complete, the steel strips are ready for the application of the coating. The coating can be applied through different techniques such as hot-dip galvanizing, electroplating, or powder coating. Each technique has its advantages and is chosen based on the specific requirements of the steel strips. In hot-dip galvanizing, the steel strips are immersed in a bath of molten zinc, which forms a protective layer on the surface. Electroplating involves passing an electric current through the steel strip while it is submerged in a plating solution. This causes a metal coating, such as chrome or nickel, to be deposited on the surface. Powder coating involves electrostatically spraying a dry powder onto the steel strip and then curing it through heat, which results in a durable and attractive finish. After the coating is applied, the steel strips are usually inspected for quality control purposes. This can involve visual inspection, thickness measurement, adhesion testing, and other checks to ensure that the coating meets the required specifications. In summary, steel strips are processed for surface coating through cleaning, pre-treatment, and application of the coating. This ensures that the surface is properly prepared for adhesion and that the coating is applied in a manner that meets the desired requirements for protection and appearance.

Send your message to us

Hot and Cold Rolled Steel Strip Coils with High Quality in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 122 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords