Steel coil aluzinc coating in different size

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 17654 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

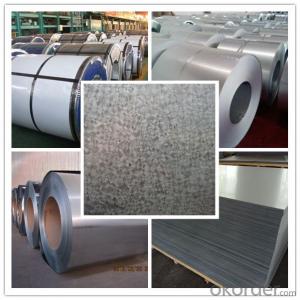

Hot –dip aluzinc steel sheet/coil is substrated on cold rolled steel (CRC) in various strength and

specification. Coating composition is 55% aluminum in weight ratio, 43.4% zinc, and 1.5% silicon,

with excellent corrosion and heat resistance performance.

The superior corrosion resistance of Galvalume steel sheet is achieved by the presence of microscopic

zinc-rich and aluminum-rich areas within the coating. The aluminum-rich areas, which corrode very slowly,

provide the long-term durability while the zinc-rich areas, which corrode preferentially, provide galvanic protection.

Standard and Grade :

Hot-dip Aluzinc steel coils | ||||

ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 | AS- 1397-2001 | |

Commercial quality | CS | DX51D+AZ | SGLCC | G1+AZ |

Structure steel | SS GRADE 230 | S220GD+AZ | SGLC400 | G250+AZ |

SS GRADE 255 | S250GD+AZ | SGLC440 | G300+AZ | |

SS GRADE 275 | S280GD+AZ | SGLC490 | G450+AZ | |

SS GRADE 340 | S320GD+AZ | SGLC570 | G450+AZ | |

SS GRADE 550 | S350GD+AZ | G500+AZ | ||

S550GD+AZ | G550+AZ | |||

Application :

Production of cold formed corrugated sheet and profiles for roofing, cladding, decking, tiles, sandwich

walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Packaging & Shipping

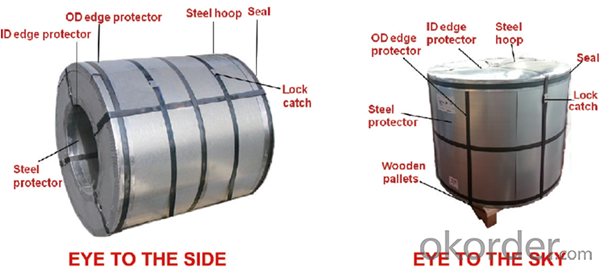

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the

specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers.

For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for

Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: What are the different types of steel coil coatings available?

- There are several different types of steel coil coatings available, including polyester, polyurethane, siliconized polyester, fluorocarbon, and plastisol coatings. Each type of coating offers specific properties and benefits, such as durability, corrosion resistance, weatherability, and aesthetics, making them suitable for various applications in industries such as construction, automotive, and appliances.

- Q: What are the challenges in coil recoiling for high-strength steel?

- Coil recoiling for high-strength steel presents several challenges that must be addressed. To begin with, high-strength steel possesses heightened hardness and strength, rendering it more difficult to coil than regular steel. The greater tensile strength of high-strength steel places additional strain on the recoiling machinery, potentially resulting in damage or machinery failure. Moreover, high-strength steel tends to exhibit reduced ductility, meaning it is less able to endure deformation without fracturing. Recoiling high-strength steel coils necessitates meticulous handling and control to prevent excessive bending or stretching that could lead to material breakage or cracking. Another obstacle arises from the shape memory effect of high-strength steel, whereby the material returns to its original shape after being deformed. Although this property can be advantageous in certain applications, it complicates the recoiling process as the steel coil resists reshaping into a new coil form. Furthermore, high-strength steel often possesses a more intricate microstructure compared to regular steel, characterized by various phases and grain boundaries. This complexity can heighten the difficulty of the recoiling process, as it can impact the material's mechanical properties and response to deformation. Finally, the surface finish of high-strength steel coils is crucial for many applications. Recoiling can introduce surface defects, such as scratches or marks, which may impair the functionality or appearance of the final product. Consequently, maintaining a high-quality surface finish during the recoiling process poses a significant challenge. In summary, the challenges associated with coil recoiling for high-strength steel encompass increased stress on recoiling equipment, reduced ductility, the shape memory effect, complex microstructure, and the need for a high-quality surface finish. Overcoming these challenges necessitates specialized equipment, precise control, and careful handling to ensure the integrity and quality of the recoiled high-strength steel coils.

- Q: How are steel coils used in the production of roofing systems?

- Steel coils are used in the production of roofing systems as they are formed into sheets or panels that are then shaped, cut, and fastened to create durable and weather-resistant roofs. The coils provide the raw material for manufacturing various components of the roofing system, such as metal tiles, standing seam panels, or corrugated sheets, which offer excellent strength, longevity, and protection against harsh elements.

- Q: How are steel coils used in the manufacturing of building materials?

- Steel coils are used in the manufacturing of building materials as they provide a strong and durable base for various products. These coils are typically unrolled and shaped into different forms, such as sheets or beams, which are then used to create structures like roofing, siding, and framing. The flexibility and strength of steel make it an ideal material for construction purposes, ensuring buildings are sturdy and long-lasting.

- Q: Steel is no doubt a better constructin material but it is only in practice in developed country.i would like that we should high lights the benifits and negatives of steel to make the steel more clear as a construction material.Hope some expert to address this topicMD

- Steel Structure considered as the most efficient and fast in completion of any project, specially the high rise buildings, also the logistics during construction is less complicated than the normal methods, Steel Structure has so many advantages vs the disadvantages, and highly recommended for commercial buildings

- Q: How are steel coils used in the manufacturing of elevator components?

- Steel coils are used in the manufacturing of elevator components as they provide the raw material for producing various parts such as brackets, frames, and structural supports. These coils are processed through cutting, bending, and shaping techniques to create the necessary components that ensure the safe and efficient operation of elevators.

- Q: What are the dimensions of steel coils used in the metalworking tool industry?

- The dimensions of steel coils used in the metalworking tool industry vary depending on the specific requirements of the tool being manufactured. However, common dimensions for steel coils in this industry range from 0.5 to 3 millimeters in thickness and 1000 to 2000 millimeters in width.

- Q: I'm going to see Man Of Steel this weekend, and the reviews that I've been hearing aren't that good. I've been hearing that it's this depressing, dark, dramatic film with no humor, loud noises, and action on top of action (which is kind of what I expected from this movie). With that said, I was quite positive that this was what the fans wanted, a more serious Super Man interpretation. I'm ultimately going to judge the movie when I see it, but for now, I have 3 short questions for you:1) What did you think of Man Of Steel?2) Superman Returns got somewhat better reviews than Man Of Steel. Does it seem logical?3) There is a huge fan battle between Man Of Steel and Christopher Reeve's version of Super Man. Which one do you favor?

- saw it yesterday and it was great. all the complaints about it being gloomy...nonsense really. how would u feel if u found out ur life was a big question mark THEN u grow up only to get tossed in giant sh*t storm. many right now are excluding this is a story driven movie/character. u can't go in expecting anything with this movie especially ANY comparison to precious films. between Reeves and Cavill... I'm not gonna make that decision yet. this portrayal was one of a complete serious nature. u only get a couple glimpses of other emotions. the ending was a great lead off in which the sequel will showcase a lot more emotion within the character guaranteed. for now Reeves is still the best. until we all see Cavill display a full form of charm and charisma then the entire debate is really pointless

- Q: What are the typical lead times for steel coil orders?

- The typical lead times for steel coil orders can vary depending on factors such as the quantity, specifications, and availability. However, on average, lead times can range from a few weeks to several months. It is recommended to check with the specific supplier or manufacturer for accurate lead time estimates.

- Q: how do i quinch steel? i heard instead of water oil will actually make it harder... wat ways are best for wat steels? and how do i tell wat kind of steel i have?... i will be doin this with my poket knife..

- boy what a though question ! let me explain. when you rapidly cool a steel from high temperatures(depending on steel type) with water or oil or other means , it is called quenching. it depends on the steel type to say if it is better to quench it with oil or water but basically in water you will have a harder steel rather than oil. for some steels if you do this you will ruin it's properties ! you can't totally tell what kind of steel do you have until you get it analyzed with Quantometer analyzer with a pocket knife it is more like an estimation and it can't be trust able generally if you can scratch the steel with your knife it means it is not a hard steel and it might not be expensive. I hope that helps but for more information i need to know more !

Send your message to us

Steel coil aluzinc coating in different size

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 17654 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords