Galvanized/Aluzinc Steel Roof High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Roof Description:

Hot-dip galvanized steel roof are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Roof:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

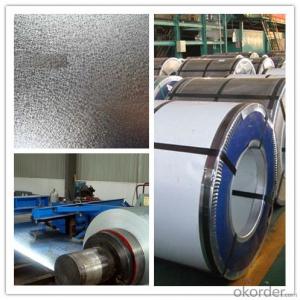

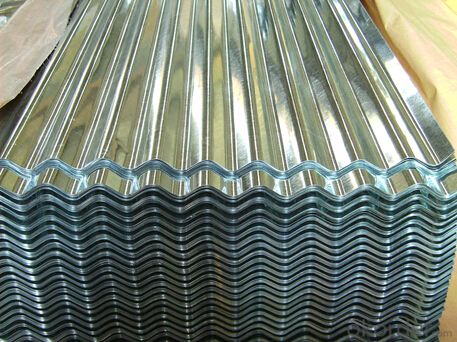

3.Hot-Dip Galvanized Steel Roof Images

4.Hot-Dip Galvanized Steel Roof Specification

Material: Galvanized Sheet

Width: 650/800/890/900

Length: 1500/1800/2000/2400/3005/3600 or customized

Thickness: 0.2-2.0

Surface Treatment: Hot dipped/Bended

Application: warehouse; shelter; Commercial facilities; industrial facilities

5.FAQ of Hot-Dip Galvanized Steel Roof

Which payment term we can do?

L/C at sight or T/T.

What’s the basic material of this product?

Galvanized/Aluzinc Steel

- Q: Want to construct a patio cover approx. 20 feet long. Only want to use a 6x6 or 8x8 post at each end. What size steel i-beam would I have to use to carry the load???

- consult your local building for the area design loads including, live dead and wind.many local steel supp;iers can design it for you.

- Q: where can i find information online about steel residential homes that use solar energy?

- Guide okorder /

- Q: I am doing a project on how revolvers work and what materials they use and would like to know what specific grade of stainless steel they use for the manufacturing of the frame and cylinder?

- *Rifle barrels are usually made from steel alloys called ordinance steel, nickel steel, chrome-molybdenum steel, or stainless steel, depending upon the requirements of the cartridge for which they are chambered. The higher the pressure and velocity of a cartridge (pressure and velocity usually go up together), the faster it will wear out a barrel. To give a satisfactory service life, barrels for high velocity cartridges must me made from tougher and harder steel than barrels for lower pressure cartridges. *The 400 (416) series SS commonly known as ordnance grade , is what barrels are made from . *If you want your barrel to be made from super alloy then it is 718 Inconel ,but a costly affair.

- Q: How are steel coils used in the production of food processing equipment?

- Steel coils are commonly used in the production of food processing equipment due to their various advantageous properties. These coils, typically made from stainless steel, are used in the manufacturing of a wide range of equipment such as mixers, blenders, conveyors, ovens, and fryers. One of the main reasons steel coils are used in food processing equipment is their excellent resistance to corrosion. Stainless steel coils are highly resistant to rust and can withstand exposure to moisture and various food substances without deteriorating. This is crucial in ensuring the equipment remains hygienic and safe for food processing. Additionally, steel coils provide exceptional strength and durability, allowing food processing equipment to withstand heavy use and harsh operating conditions. The coils can be formed into different shapes and sizes, enabling the fabrication of complex equipment components. This versatility facilitates the design and construction of equipment that is both efficient and reliable in processing various food products. Furthermore, steel coils are easy to clean and maintain. The smooth surface of stainless steel makes it resistant to staining and facilitates the removal of food residues, preventing the growth of bacteria. Regular cleaning and sanitization of food processing equipment are essential for maintaining food safety standards, and steel coils make this process easier and more effective. Moreover, steel coils have excellent heat conductivity properties, allowing for efficient heat transfer in food processing equipment such as ovens and fryers. This enables precise temperature control and uniform cooking, ensuring consistent quality of processed food products. In summary, steel coils play a vital role in the production of food processing equipment by providing corrosion resistance, strength, durability, ease of cleaning, and efficient heat transfer. These qualities make steel coils an ideal material for manufacturing equipment that meets the high standards of hygiene, safety, and quality required in the food processing industry.

- Q: How are steel coils used in the manufacturing of HVAC ductwork?

- Steel coils are used in the manufacturing of HVAC ductwork as they provide the necessary strength and durability required for the ductwork. These coils are typically processed through a roll-forming machine, which shapes them into the required ductwork profile. The steel coils are then cut to the desired length, welded or joined together, and finally, coated to prevent corrosion and improve the overall performance of the ductwork.

- Q: Im in the process of replacing the gutters/down spouts on my house. The top of the house is four sided. The bottom level has a porch area with 3 sides, two smaller roofs in the back, and one small roof on the side with all stainless steel gutters. A two story house. Not sure of the demensions. They were made at a Steel Mill where the previous owner, worked.This guy wants to buy the stainless gutters but I need to know the market value of this steel and offer him a price. Can someone tell me what I can sell it for? Does it go by the pound? Foot? Can you give me an idea please? Theres a lot of it! I have no clue what to do! Thanks!

- i know it goes buy the pound but i do not know how mutch a pound.waite for some more answers someone must know.or call your local junk yard and ask them.

- Q: What are the dimensions of steel coils used in the oil and gas industry?

- The dimensions of steel coils in the oil and gas industry can differ based on the specific application and needs. Nevertheless, there are commonly used dimensions. Steel coils in the oil and gas industry typically possess a width that ranges from 600mm to 2000mm. The coil's outer diameter can vary from 800mm to 2200mm, while the inner diameter can range from 508mm to 610mm. The coil's weight can also vary, ranging from a few tons to several tens of tons. These dimensions are tailored to fulfill the requirements of diverse processes in the oil and gas industry, including pipe manufacturing, storage tank fabrication, and offshore platform construction. It is important to emphasize that these dimensions are not fixed and can be customized to meet the specific demands of each project.

- Q: What are the different surface treatments for steel coils?

- There are several different surface treatments available for steel coils, depending on the desired outcome and application. Some of the most common surface treatments for steel coils include: 1. Hot-dip galvanizing: This process involves immersing the steel coils in a bath of molten zinc, which forms a protective layer on the surface of the steel. Hot-dip galvanizing provides excellent corrosion resistance and is often used for outdoor applications. 2. Electro-galvanizing: Similar to hot-dip galvanizing, but instead of immersing the steel coils in molten zinc, a thin layer of zinc is electroplated onto the surface of the steel. Electro-galvanizing provides good corrosion resistance and is commonly used for indoor applications. 3. Powder coating: This process involves applying a dry powder to the surface of the steel coils, which is then heated and cured to form a hard, durable coating. Powder coating provides excellent corrosion resistance and is available in a wide range of colors and finishes. 4. Paint coating: Steel coils can also be coated with a liquid paint, which provides both corrosion resistance and aesthetic appeal. Paint coatings can be applied in various thicknesses and finishes, depending on the desired look and level of protection required. 5. Phosphating: Phosphating is a chemical treatment that involves immersing the steel coils in a phosphate solution. This process creates a thin, adherent layer of phosphate on the surface of the steel, which enhances paint adhesion and improves corrosion resistance. 6. Chromate conversion coating: Also known as chromating or passivation, this process involves immersing the steel coils in a solution containing chromium salts. Chromate conversion coatings provide excellent corrosion resistance and also act as a primer for subsequent paint or powder coating. 7. Zinc-nickel plating: This surface treatment involves electroplating a layer of zinc-nickel alloy onto the steel coils. Zinc-nickel plating provides superior corrosion resistance compared to pure zinc plating and is often used in demanding environments. These are just a few of the many surface treatments available for steel coils. The choice of treatment depends on factors such as the application, desired level of corrosion resistance, aesthetic requirements, and budget. It is important to carefully consider the specific needs of the project and consult with experts to determine the most suitable surface treatment for steel coils.

- Q: I was wondering whether anyone knew if painted steels rusts at the same speed as steel that isn't painted. Also, does steel rust quicker than aluminium?Thank you

- Painting a piece of steel will coat it with a protective layer, causing it to not rust (not get oxidised). Aluminum does not rust.

- Q: Question about steel type used in bridges.?

- Do you mean galvanized steel?

Send your message to us

Galvanized/Aluzinc Steel Roof High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords