Standard Steel Pipe Seamless A192-02 America Standard Steel Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 kg

- Supply Capability:

- 9700 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Seamless A192-02 America Standard Steel Tube :

Seamless A192-02 America Standard Steel Tube is to be used for conveying gas, water, and petroleum foroil and natural gas industries. And used for structural steel pies purpose. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of Seamless A192-02 America Standard Steel Tube :

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless A192-02 America Standard Steel Tube ,Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM SPEC 5CT-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless A192-02 America Standard Steel Tube :

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

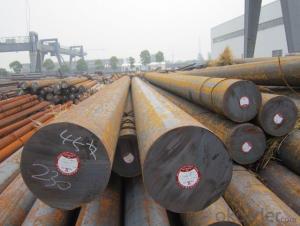

6、 Seamless A192-02 America Standard Steel Tube : Images:

- Q: How does special steel contribute to the telecommunications aftermarket industry?

- Special steel plays a crucial role in the telecommunications aftermarket industry by providing the necessary materials for the manufacturing and maintenance of various telecommunications equipment. This type of steel is specifically designed to possess exceptional properties, such as high strength, corrosion resistance, and durability, which are essential for the demanding conditions of the telecommunications sector. One of the main contributions of special steel to the telecommunications aftermarket industry is its use in the production of communication towers and transmission structures. These structures need to withstand extreme weather conditions, including strong winds and heavy loads, while also providing reliable support for antennas and other equipment. Special steel is capable of meeting these requirements, ensuring the longevity and stability of communication towers. Furthermore, special steel is extensively used in the manufacturing of cables and wires used in telecommunications systems. These cables need to transmit signals without any loss or interference, and the unique properties of special steel, such as high electrical conductivity and low resistance, make it an ideal material for this purpose. The use of special steel in cables helps maintain the quality and efficiency of telecommunications networks. Another significant contribution of special steel is in the production of equipment enclosures and cabinets. These enclosures provide protection to sensitive electronic components from environmental factors, such as moisture, dust, and extreme temperatures. Special steel, with its corrosion-resistant properties, ensures the longevity and reliability of these enclosures, safeguarding the valuable equipment inside. Moreover, special steel is also utilized in the manufacturing of various components and accessories used in the telecommunications aftermarket industry. These include connectors, brackets, and hardware, which are essential for assembling and maintaining telecommunications equipment. Special steel's high strength and durability make it a preferred choice for these components, ensuring their long-lasting performance. In conclusion, special steel contributes significantly to the telecommunications aftermarket industry by providing the necessary materials for the manufacturing and maintenance of various telecommunications equipment. Its exceptional properties, including high strength, corrosion resistance, and durability, make it an ideal choice for communication towers, cables, enclosures, and various components. By utilizing special steel, the telecommunications industry can ensure the reliability, efficiency, and longevity of its equipment, ultimately benefiting both service providers and end-users.

- Q: What are the requirements for special steel used in low-temperature applications?

- The requirements for special steel used in low-temperature applications include high toughness, excellent resistance to brittle fracture, and good ductility at low temperatures. It should have a low carbon content to prevent embrittlement, along with specific alloying elements like nickel, manganese, and chromium to enhance its low-temperature properties. Additionally, the steel should have good weldability and corrosion resistance to withstand the harsh conditions often encountered in low-temperature environments.

- Q: How does wear-resistant steel protect against abrasive wear?

- Wear-resistant steel protects against abrasive wear by having a high hardness and toughness, which allows it to withstand the abrasive forces and prevent material loss or surface damage. The steel's composition and heat treatment provide it with enhanced resistance to abrasive particles, reducing wear and extending the lifespan of the material.

- Q: Can special steel be used for medical applications?

- Yes, special steel can be used for medical applications. Specialized types of stainless steel, such as AISI 316L or 316LVM, are commonly used in medical devices and implants due to their excellent corrosion resistance, biocompatibility, and strength. These steels are often used in surgical instruments, orthopedic implants, cardiovascular devices, and many other medical applications.

- Q: What are the main alloying elements in special steel?

- The main alloying elements in special steel are chromium, nickel, molybdenum, vanadium, and tungsten.

- Q: Can special steel be used in power generation applications?

- Yes, special steel can certainly be used in power generation applications. Special steel refers to various types of steel that are specifically designed to have enhanced properties such as high strength, durability, heat resistance, corrosion resistance, and wear resistance. These properties make special steel ideal for use in power generation applications where the materials need to withstand high temperatures, pressures, and mechanical stresses. In power generation, special steel can be used in various components and equipment, such as turbine blades, boiler tubes, heat exchangers, steam pipes, and high-pressure valves. For example, in thermal power plants, where fossil fuels are burned to generate electricity, special steel is commonly used in boiler tubes and heat exchangers to withstand the high temperatures and pressures of the steam generation process. Additionally, in nuclear power plants, special steel is used in critical components like reactor vessels, steam generators, and fuel cladding due to its excellent strength, resistance to radiation damage, and corrosion resistance. Furthermore, special steel is also used in renewable energy power generation applications. For instance, in wind turbines, special steel is used in the construction of turbine towers, rotor blades, and gearboxes, as it needs to withstand high wind speeds, vibrations, and fatigue. Overall, special steel plays a crucial role in power generation applications due to its exceptional properties, ensuring the reliability, efficiency, and longevity of the equipment and components used in various power generation systems.

- Q: Can special steel be used in the cement manufacturing industry?

- Yes, special steel can be used in the cement manufacturing industry. Special steel, such as heat-resistant and wear-resistant steel, can be utilized in various components and machinery used in cement manufacturing processes. These steels are designed to withstand high temperatures, abrasion, and corrosion, making them suitable for applications in kilns, crushers, mills, and other equipment involved in cement production.

- Q: What are the properties of electrical steel?

- Electrical steel, also known as silicon steel, possesses specific properties that make it ideal for use in electrical equipment. It exhibits low core loss, high permeability, and high magnetic saturation, enabling efficient energy conversion and minimizing power losses. Additionally, electrical steel has a high resistivity, reducing eddy currents and further improving its performance in transformers, motors, and generators.

- Q: What are the main characteristics of high-speed steel forgings?

- Highly desirable in various industries are high-speed steel forgings, which possess several key characteristics. To begin, the exceptional hardness and wear resistance of high-speed steel forgings are noteworthy. This is a result of their composition, which typically includes elements like tungsten, molybdenum, chromium, and vanadium. These elements create hard carbides within the steel matrix, leading to a material capable of enduring high temperatures and resisting abrasion and deformation. Additionally, high-speed steel forgings exhibit excellent heat resistance, enabling them to maintain their hardness and strength even at elevated temperatures. This is particularly significant in applications where tools or components undergo intense heat during operation. Another important trait of high-speed steel forgings is their ability to retain a sharp cutting edge for extended periods. This proves advantageous in cutting tools, where an efficient and precise machining process relies on a sharp edge. The steel's high hardness ensures the cutting edge remains sharp, resulting in enhanced tool life and performance. Moreover, high-speed steel forgings demonstrate good toughness and impact resistance, making them less vulnerable to cracking or chipping under heavy loads or sudden impacts. This ensures their durability and reliability in demanding applications. In addition to these mechanical properties, high-speed steel forgings possess excellent machinability. They can be easily shaped, formed, and machined into intricate geometries, making them ideal for producing complex components or tools. Overall, the main characteristics of high-speed steel forgings encompass exceptional hardness, wear resistance, heat resistance, cutting edge retention, toughness, impact resistance, and machinability. These qualities render them highly sought-after in industries such as aerospace, automotive, tooling, and machining, where performance, reliability, and longevity are of utmost importance.

- Q: What are the different methods for case hardening special steel?

- There are several methods for case hardening special steel, including carburizing, nitriding, carbonitriding, and induction hardening. Carburizing involves heating the steel in a carbon-rich environment to allow carbon atoms to diffuse into the surface, creating a hardened outer layer. Nitriding, on the other hand, involves introducing nitrogen to the steel's surface, resulting in a hard and wear-resistant layer. Carbonitriding combines both carbon and nitrogen to create a hardened surface with improved wear and corrosion resistance. Lastly, induction hardening utilizes an electromagnetic field to heat and harden specific areas of the steel, providing localized hardness and strength.

Send your message to us

Standard Steel Pipe Seamless A192-02 America Standard Steel Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 kg

- Supply Capability:

- 9700 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords