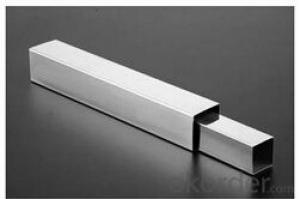

Stainless welded square steel pipe 9.5x15mm~63x133mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Name: Stainless welded square steel tube and pipe

1) Material: Stainless steel

2)Standards:300series

3) Shape:square pipe

4) Type: stainless steel square pipe

5) Surface: Pickling, Sand, Polished

6) Sizes range: 9.5x15mm~63x133mm

7) Wall thickness:0.5m~3.0mm

8)Packing:Export sea worthy package

9) Payment:T/T 30%payment in advance, 70% T/T before shipment or by L/C

10) Delivery:Within30days after receiving 30%T/T of deposit or L/C

Name | Stainless welded square steel tube and pipe |

Standard: | 300series |

Type | stainless steel square pipe |

Material | Stainless steel |

Shape | square pipe |

Sizes range | 9.5x15mm~63x133mm |

Wall thickness | 0.5m~3.0mm |

surface finish | Pickling, Sand, Polished |

Packing: | Export sea worthy package |

Delivery: | Within 30days after receiving 30%T/T of deposit or L/C |

MOQ: | 1Metric Ton/Metric Tons |

Price terms: | FOB, CFR, CIF |

Payment terms: | T/T, L/C |

Application | Stainless Steel square Pipe applies to Petroleum & chemical industries, construction field, machinery and hardware fields, food processing and medical industry, high or low temperature resistant, electricity industries, etc. |

Quality control: | a)Mill Test Certificate is supplied with shipment. b)Third party inspection is highly welcomed. |

Advantage | a) Strong processing and warehousing service b) Stock available c) Strict quality control |

- Q: How do you prevent freezing in stainless steel pipes?

- One way to prevent freezing in stainless steel pipes is by insulating them with high-quality pipe insulation. This insulation helps maintain the temperature of the pipes and prevents heat loss, thus reducing the risk of freezing. Additionally, ensuring proper ventilation in areas where the pipes are located can also help prevent freezing by allowing warm air to circulate around the pipes.

- Q: Can stainless steel pipes be stress relieved?

- Yes, stainless steel pipes can be stress relieved. Stress relieving is a heat treatment process that helps to reduce residual stresses in the material, improving its mechanical properties and reducing the risk of cracking or distortion. This process can be applied to stainless steel pipes to enhance their performance and durability.

- Q: Are stainless steel pipes suitable for underground applications?

- Indeed, underground applications are well-suited for the utilization of stainless steel pipes. Renowned for its remarkable resistance to corrosion, stainless steel proves to be an exceptional selection for installations that are situated beneath the surface, where pipes are regularly exposed to moisture, soil, and other detrimental elements. Its ability to endure harsh environments while maintaining its structural integrity over time is truly impressive. Moreover, stainless steel pipes possess superior strength and durability, enabling them to withstand the immense pressure and stress associated with being buried underground. Furthermore, the non-reactive nature of stainless steel ensures that the water or fluid flowing through these pipes remains uncontaminated. Overall, stainless steel pipes can be relied upon as a dependable and long-lasting solution for underground applications.

- Q: What is the average lead time for manufacturing stainless steel pipes?

- The average lead time for manufacturing stainless steel pipes can vary depending on several factors such as the complexity of the design, quantity required, and the manufacturer's production capacity. However, on average, it can range from a few weeks to a couple of months.

- Q: How do you calculate the maximum allowable span for stainless steel pipes?

- The maximum allowable span for stainless steel pipes can be calculated by considering various factors such as the material's tensile strength, the pipe's diameter, wall thickness, and the type of support or loading conditions. By using engineering formulas and standards specific to stainless steel pipes, such as those provided by ASME B31.1 or ASME B31.3, one can determine the maximum span that ensures structural integrity and safety.

- Q: Are stainless steel pipes suitable for mining applications?

- Yes, stainless steel pipes are suitable for mining applications due to their excellent corrosion resistance, high strength, and durability. They can withstand harsh environments, extreme temperatures, and the corrosive nature of mining fluids, making them ideal for transporting and distributing various materials in the mining industry.

- Q: Can stainless steel pipes be insulated with polyvinylidene fluoride?

- Yes, stainless steel pipes can be insulated with polyvinylidene fluoride (PVDF). PVDF is a high-performance fluoropolymer that offers excellent thermal and chemical resistance properties, making it suitable for insulating stainless steel pipes in various industrial applications.

- Q: Can stainless steel pipes be threaded with NPT threads?

- Indeed, NPT threads can be applied to stainless steel pipes. NPT, a prevalent standard for pipe threads in the United States, is compatible with stainless steel as well as various other materials. Nevertheless, it is crucial to acknowledge that stainless steel possesses greater strength and hardness compared to alternative materials, necessitating increased caution and attentiveness during the threading procedure. Moreover, employing lubricants or cutting fluids specifically formulated for stainless steel is advised to guarantee a seamless and precise threading operation.

- Q: What is the difference between 304J7 and 316J7 stainless steel pipes?

- The main difference between 304J7 and 316J7 stainless steel pipes lies in their composition and properties. 304J7 stainless steel is part of the 304 series, which is a widely used stainless steel grade known for its excellent corrosion resistance and durability. It contains around 18-20% chromium and 8-10% nickel, which contribute to its corrosion resistance and make it suitable for various applications, including plumbing, food processing, and chemical industries. On the other hand, 316J7 stainless steel belongs to the 316 series, which is a higher grade of stainless steel compared to 304. It contains a higher amount of chromium (16-18%) and nickel (10-14%) as well as the addition of molybdenum (2-3%), which further enhances its corrosion resistance, especially against chlorides and other aggressive environments. This makes 316J7 stainless steel pipes ideal for applications such as marine environments, coastal areas, and chemical processing plants. In terms of mechanical properties, 316J7 stainless steel pipes generally have higher tensile strength and creep resistance compared to 304J7. This makes them more suitable for high-pressure and high-temperature applications. Furthermore, 316J7 stainless steel pipes are often considered more expensive than 304J7 due to their superior corrosion resistance and enhanced properties. However, the specific pricing may vary depending on market conditions and other factors. In summary, while both 304J7 and 316J7 stainless steel pipes offer good corrosion resistance, 316J7 is a higher grade with superior resistance to chlorides and aggressive environments. The choice between the two will depend on the specific application requirements, budget, and environmental factors.

- Q: Can stainless steel pipes be used for petrochemical applications?

- Yes, stainless steel pipes can be used for petrochemical applications. Stainless steel is highly resistant to corrosion and can withstand high temperatures, making it suitable for transporting and storing petrochemicals safely and efficiently.

Send your message to us

Stainless welded square steel pipe 9.5x15mm~63x133mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords