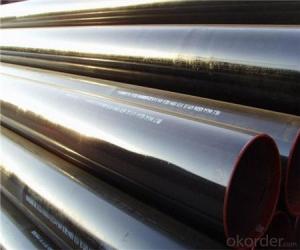

ERW STEEL PIPE API 5L/ASTM A53/ASTM A106

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1)Outside Diameter: 10.3mm--914.4mm

2)Wall Thickness: 0.5~59.54mm

3)Length: Random 1~12m or fixed 6

4)Material quality: ASTM A106 / A53/A210, API 5L,API 5CT,DIN, EN, GB/T8162 / 8163, etc

5)Packing:Hexangular packing in bundles

6)Export: Europe, North America, the Middle East, Africa, Asia and other countries and regions, well received by consumers!

Product Name: | ERW pipe | |

Size | OD | 1/8” -24” (10.3mm-914.4mm) |

Wall Thickness | 0.5mm-59.54mm SCH30,SCH40,STD,XS,SCH80,SCH,XXS | |

Length | 1m-12m | |

Steel material | Q195,Q215,Q235,Q345,STL400,ST37-2,16Mn,X42,X52,X80,E235, Grade B, SS330,SPHC, S185,SS400,S235JR,ST52,STK500 | |

Standard | BS1387-1985,ASTM A53,ASTM A106,GB/T3091-93-2008,EN10129,JIS. | |

Usage | Used For irrigation,Structure, Accessorize And Construction | |

Ends | 1) Plain 2) Beveled 3) Threaded with Coupling & cap | |

Surface Treatment | 1) Bared 2) Black Painted (varnish coating) 3) Galvanized 4) With Oiled | |

Technique | Electronic Resistance Welded (ERW ) Electronic Fusion Welded (EFW) Double Submerged Arc Welded (DSAW) | |

Welded Line Type | Longitudinal | |

Inspection | With Hydraulic Test, Eddy Current , Infrared Test | |

Package | In Bundle with water-proof package | |

Delivery | 1) Container 2) Bulk carrier | |

Port of Shipment | Xingang Port,Tianjin, China | |

Date of Delivery | 15 days after contract | |

Payment | L/C at sight or 30% T/T | |

Others | Fitting as coupler and flange also can be supplied. | |

- Q: What is the average cost of steel pipes?

- The average cost of steel pipes can vary significantly depending on factors such as size, grade, and quantity needed. Therefore, it is difficult to provide a specific average cost without more information.

- Q: How are steel pipes used in the construction of highways?

- Steel pipes are commonly used in the construction of highways for various purposes, such as drainage systems, culverts, and sign supports. They provide a durable and efficient solution for transporting stormwater and preventing damage to the road surface. Additionally, steel pipes are utilized to support highway signs and traffic signals, ensuring their stability and longevity.

- Q: Can steel pipes be used for automotive applications?

- Yes, steel pipes can be used for automotive applications. Steel pipes are commonly used for various automotive components such as exhaust systems, fuel lines, and structural frames due to their high strength, durability, and resistance to corrosion. They provide reliable performance and are cost-effective in automotive manufacturing.

- Q: How are steel pipes used in the oil and gas industry?

- Steel pipes are widely used in the oil and gas industry for various purposes. They are primarily used for transporting oil and gas from production sites to refineries and distribution centers. These pipes are known for their strength, durability, and resistance to corrosion, making them ideal for handling the high-pressure and corrosive nature of oil and gas fluids. Steel pipes are also used in drilling operations as casing and tubing to maintain the integrity of the wellbore and prevent any leakage. Additionally, steel pipes are utilized in the construction of oil and gas infrastructure such as pipelines, storage tanks, and offshore platforms, ensuring the safe and efficient transportation and storage of oil and gas resources.

- Q: What are the common applications of steel pipes in industrial settings?

- Steel pipes have a wide range of applications in industrial settings, including but not limited to, the transportation of fluids and gases, structural supports in buildings and infrastructure, manufacturing of machinery and equipment, and even in the oil and gas industry for drilling and extraction purposes.

- Q: Are steel pipes more expensive than other types of pipes?

- The cost of steel pipes can vary compared to other pipe types due to various factors. In terms of upfront cost, steel pipes are generally more expensive than certain pipe types. This is primarily because the production process and raw materials for steel pipes are highly costly. Additionally, steel pipes are renowned for their strength and durability, making them a popular option for applications involving high pressure or extreme conditions. However, when considering long-term costs and benefits, steel pipes are often more economically viable. They have a longer lifespan compared to certain pipes, reducing the need for frequent repairs or replacements. Furthermore, steel pipes possess excellent corrosion resistance, making them suitable for diverse environments and reducing maintenance expenses over time. Moreover, the strength and durability of steel pipes contribute to a reduced likelihood of leaks or failures, resulting in significant cost savings to prevent damage or loss. When comparing the cost of steel pipes to other pipe types, it is crucial to consider the specific requirements and characteristics of the project or application. Factors like the transported fluid or material, required pressure rating, expected lifespan, and environmental conditions should all be taken into account. Ultimately, despite steel pipes having a higher upfront cost, their long-term durability and reliability often make them a cost-effective choice in numerous applications.

- Q: Can steel pipes be used for transporting gases and liquids?

- Yes, steel pipes can be used for transporting gases and liquids. Steel pipes are known for their high strength, durability, and resistance to corrosion, making them an ideal choice for transporting various substances. Additionally, steel pipes have the ability to withstand high pressure and temperature, making them suitable for a wide range of applications in industries such as oil and gas, water supply, and chemical processing.

- Q: Can steel pipes be used for the construction of tunnels?

- Yes, steel pipes can be used for the construction of tunnels. Steel pipes are often used as structural elements for tunnel construction due to their strength, durability, and resistance to corrosion. They can be used for various purposes such as tunnel lining, ventilation systems, and water drainage. Steel pipes offer the advantage of being able to withstand high loads and pressures, making them suitable for tunnel construction in different geological conditions.

- Q: What is the cost of steel pipes?

- The cost of steel pipes can vary depending on factors such as the size, grade, and quantity needed, as well as market conditions and supplier. It is recommended to contact suppliers or check online platforms to get specific pricing information.

- Q: How seamless steel tube is formed?

- Hot drawing or cold drawing. The so-called cold is the billet from the thick wall tube is not heated, oil lubrication, with a steel sleeve inside, gradually elongated. Hot drawing is to make the billet tube red, do such work, generally thick wall applicable.

Send your message to us

ERW STEEL PIPE API 5L/ASTM A53/ASTM A106

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords