Factory price 304L stainless steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

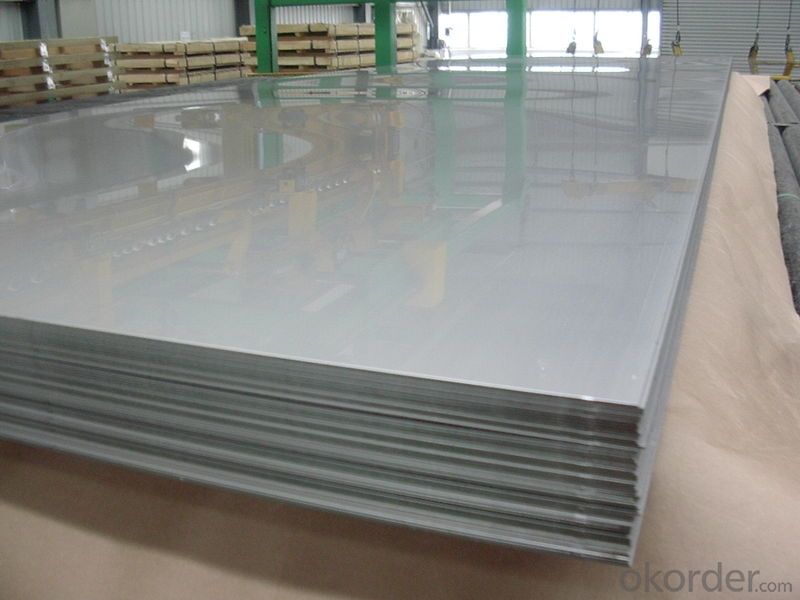

Factory price 304L stainless steel sheet !!!

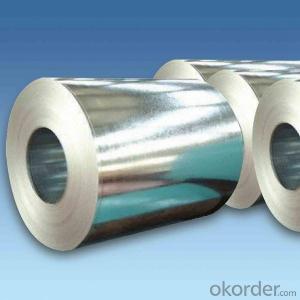

1.hot rolled and cold rolled stainless steel sheet detailed information:

Type | 304L stainless steel sheet |

Thinckness | 0.3mm-60mm |

Widthness | 50mm~2000mm |

Length | 2000mm~8000mm or as request |

Brand name | TISCO |

Standard | JIS, AISI, ASTM, GB, DIN, EN |

Material | 304L,304,316,316L,309S,310S,321,317,301,904L,201,202,430,410,420, etc |

Surface | 2B,BA,HL,BK,NO.1,NO.4,etc |

Certificate | We accept the third inspections |

Application | Bridge, Shipbuilding,roofing,Car, etc |

Payment | T/T, 30% deposit, blance before loading, L/C |

Note | We can produce other standard as the customers’ require |

2. 304L stainless steel sheet Applications :

| Finish | Thickness | Characteristics | Applications |

| No. 1 | 3.0mm~50.0mm | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface | Chemical industry equipment, Industrial tanks |

| No. 2B | 0.3mm~6.0mm | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be more brighter and smooth surface | General Application Medical Instruments,Tableware |

| No. BA (Bright Annealed) | 0.5mm~2.0mm | Bright heat treatment after cold rolling | Kitchen utensil, kitchen ware,architectural purpose |

| No. 4 | 0.4mm~3.0mm | Polishing with No. 150 to No.180 mesh abrasivesThe most popular finishes | Milk & Food processing acilities, Hospital Equipment, Bath-tub |

| HL(Hair Line) | 0.4mm~3.0mm | Finished by continuous linear polishing | Architectural purposes, escalators, kitchen ware vehicles |

Why do you choose us?

1) Our products are high quality and best price.

2)We have experience in this line for many years.

3)We have professional team and the factory.

4)It's very important for a company to be honest in the process of trading and so do we.

- Q: Are stainless steel pipes suitable for wastewater treatment plants?

- Yes, stainless steel pipes are highly suitable for wastewater treatment plants. They offer excellent corrosion resistance, durability, and strength, ensuring long-term reliability and minimal maintenance requirements. Stainless steel pipes can withstand the harsh and corrosive conditions found in wastewater treatment plants, making them an ideal choice for conveying and handling various types of wastewater.

- Q: How do stainless steel pipes compare to PVC pipes?

- Stainless steel pipes are generally more durable, have higher heat resistance, and are better suited for high-pressure applications compared to PVC pipes. While PVC pipes are lightweight, cost-effective, and easier to install, they are prone to cracking, chemical reactions, and may not be suitable for certain environments. Therefore, the choice between stainless steel and PVC pipes depends on the specific needs of the application.

- Q: Can stainless steel pipes be laser welded?

- Yes, stainless steel pipes can be laser welded.

- Q: What are the specifications of stainless steel decorative pipes?

- Decorative tubes, then more specifications. Our factory has the smallest 9.5MM, the largest to see how big you can, directly with the industrial pipe to polish it

- Q: What is the difference between 304J2 and 316J2 stainless steel pipes?

- The main difference between 304J2 and 316J2 stainless steel pipes lies in their chemical composition and the presence of certain elements. 304J2 stainless steel is a variant of the popular 304 stainless steel grade. It contains around 18-20% chromium and 8-10.5% nickel, which gives it good corrosion resistance, especially in mildly corrosive environments. However, it has a lower molybdenum content compared to 316J2. On the other hand, 316J2 stainless steel is a variant of the 316 stainless steel grade. It contains around 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The higher molybdenum content enhances its corrosion resistance, making it suitable for more aggressive environments, such as marine or chemical applications. In terms of mechanical properties, both grades have similar tensile strength and yield strength. However, due to the higher nickel and molybdenum content, 316J2 stainless steel pipes generally offer better resistance to pitting and crevice corrosion. Overall, the choice between 304J2 and 316J2 stainless steel pipes depends on the specific application and the level of corrosion resistance required. While 304J2 is suitable for general use in mildly corrosive environments, 316J2 is preferable for applications where exposure to more aggressive conditions is expected.

- Q: What are the common standards used for manufacturing stainless steel pipes?

- The common standards used for manufacturing stainless steel pipes include ASTM A312/A312M, ASTM A269, and ASTM A790.

- Q: Can stainless steel pipes be used for food processing?

- Yes, stainless steel pipes can be used for food processing. Stainless steel is a popular choice in the food industry due to its excellent corrosion resistance, high strength, and hygiene properties. It is non-reactive, which means it does not interact with food and does not impart any taste or odor. Stainless steel pipes are easy to clean, sanitize, and maintain, making them suitable for use in food processing applications where cleanliness and hygiene are crucial. Additionally, stainless steel pipes can withstand high temperatures and pressures, making them ideal for various food processing operations such as transportation, storage, and distribution of food products.

- Q: How do you clean stainless steel pipes?

- To effectively clean stainless steel pipes, various methods can be employed depending on the extent of dirt or grime present. To begin with, warm water and a mild detergent can be utilized. The detergent should be mixed with water and a soft cloth or sponge can be used to gently wipe the surface of the pipes. It is important to ensure that the wiping motion follows the direction of the grain in order to prevent any scratching of the steel. Following this, the pipes should be thoroughly rinsed with clean water and dried with a clean, lint-free cloth. In cases where the pipes exhibit tougher stains or buildup, a vinegar solution can be employed. Equal parts of vinegar and water should be mixed and the resultant solution can be applied to the pipes. Allowing it to sit for a few minutes will enable the solution to dissolve the stains, after which a soft brush or cloth can be used to gently scrub the pipes. Subsequently, the pipes should be well-rinsed with clean water and thoroughly dried. For more stubborn stains or discoloration, the utilization of a specialized stainless steel cleaner or polish is recommended. The product's instructions should be followed, typically involving its application to the pipes and subsequent rubbing with a soft cloth, once again following the direction of the grain. The pipes must then be rinsed extensively with clean water and completely dried. It should be noted that abrasive cleaners or scrubbing pads must be avoided as they possess the potential to scratch the stainless steel surface. Furthermore, it is advisable to always test any cleaning solution or product on a small, inconspicuous area of the pipes before applying it to the entire surface. This ensures that no damage or discoloration occurs.

- Q: How do you prevent contamination in stainless steel pipes?

- To prevent contamination in stainless steel pipes, it is crucial to follow a few important steps. Firstly, regular cleaning and maintenance are essential. This involves using appropriate cleaning agents and techniques to remove any dirt, debris, or potential contaminants from the pipes. It is important to avoid using abrasive materials or harsh chemicals that can damage the stainless steel surface. Secondly, ensuring proper installation and sealing of the pipes is crucial. Any gaps or leaks in the connections can allow contaminants to enter the system. It is advisable to use high-quality fittings and seals to ensure a tight and secure connection. Thirdly, implementing a comprehensive filtration system can help prevent contamination. Filters can remove impurities such as sediments, particles, and other contaminants that may be present in the fluid or gas flowing through the pipes. Regularly inspecting and replacing these filters is important to maintain their efficiency. Additionally, regular inspection and monitoring of the pipes is essential. This includes checking for signs of corrosion, rust, or any other damage that can compromise the integrity of the pipes. Promptly addressing any issues that arise can prevent contamination and extend the lifespan of the stainless steel pipes. Lastly, it is crucial to establish and follow proper hygiene practices. This includes implementing procedures to minimize the introduction of contaminants during maintenance or repairs. It is also important to train personnel on proper handling techniques and the importance of maintaining cleanliness and hygiene when working with stainless steel pipes. By following these preventive measures, it is possible to minimize the risk of contamination in stainless steel pipes, ensuring the integrity and longevity of the system.

- Q: Can stainless steel pipes be used for desalination plants?

- Yes, stainless steel pipes can be used for desalination plants. Stainless steel is a highly corrosion-resistant material, which makes it suitable for use in desalination plants where the water contains high levels of salt and other corrosive substances. The high corrosion resistance of stainless steel pipes helps to prevent the buildup of scale and the formation of rust, ensuring the longevity and efficiency of the desalination plant. Additionally, stainless steel pipes are also known for their high strength and durability, which can withstand the high pressure and temperature conditions often found in desalination plants. Overall, stainless steel pipes are an ideal choice for desalination plants due to their corrosion resistance, strength, and durability.

Send your message to us

Factory price 304L stainless steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords