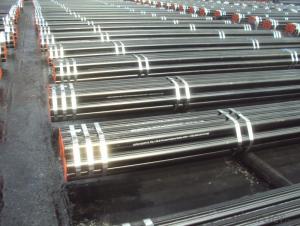

Stainless steel welded pipe variety specification

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless steel welded pipe is currently mainly used in heat exchanger tube, fluid pipe, pressure pipe, mechanical structure tube, city landscape, professions and so on

Welded steel pipe with high precision, uniform wall thickness, pipe inside and outside surface of high brightness (steel plate surface brightness surface level decision), can be arbitrary fixed length. Therefore, it reflects the economy and its aesthetics in high precision, low voltage applications in fluid.

| Name | 2 inch Stainless Steel Pipe,Welded Stainless Steel Pipe China Manufacture |

Material | 304:0cr18ni9, 0cr17ni8 201:1cr17mn6ni5n,1cr13mn9ni1n 316:0cr17ni12 or as customer’s request |

Size(round pipe) | 9.5, 12.7, 15.9, 17, 18, 19.1, 20, 21, 22.2, 23, 25.4, 28, 318, 35, 60, 63.5, 73, 76.2, 88.9, 101.6, 114.3, 127, 133, 159, 168, 219 mm or customized |

Size (square pipe) | 10×10,12×12,18×18,23×23,38×38,50×50,70×70,100×100,20×10,23×10,24×12,25×13,36×23,40×20,50×20, 60×15,75×45,80×60,95×45,100×60,150×100 mm or customized |

Size (oval pipe) | 30×15,80×40 mm os customized |

Thickness | 0.25-3 mm |

Length | 6m or according to customer’s request |

Outer diameter | 6.35-219mm |

Tolerance | Outer diameter :±0.2mm |

Thickness :±0.02mm | |

Length :±0.5mm | |

Process method | Code down, annealed with nitrogen protection, ultrasonic,automatic shape, polished |

Finishing | A: sanded B: 400#-600# mirror C: hairline brushed D: TIN titanlum E : HL brushed & mirror (two kinds of finishing for one pipe |

- Q: What is the difference between 316 and 316LN stainless steel pipes?

- 316 and 316LN stainless steel pipes are variations of the same stainless steel grade known as 316, but there are some distinctions between them. The primary disparity between 316 and 316LN stainless steel pipes resides in their nitrogen levels. 316LN stainless steel contains a higher nitrogen content than 316 stainless steel. The inclusion of nitrogen enhances the material's strength and corrosion resistance, making it more suitable for specific applications. Due to its elevated nitrogen content, 316LN stainless steel pipes display superior resistance to pitting and crevice corrosion, especially in chloride environments. This renders them particularly appropriate for utilization in marine settings or other scenarios where the pipes may encounter corrosive substances. Another contrast between the two grades lies in their availability and cost. 316 stainless steel pipes are more widely accessible and commonly employed, making them generally more cost-effective than 316LN stainless steel pipes. However, 316LN stainless steel pipes may be necessary for particular applications where enhanced corrosion resistance is required. In conclusion, the main difference between 316 and 316LN stainless steel pipes is their nitrogen content, which impacts their corrosion resistance properties. While 316 stainless steel is more readily available and cost-effective, 316LN stainless steel offers improved resistance to pitting and crevice corrosion, making it suitable for specific applications.

- Q: Can stainless steel pipes be used for brewery equipment?

- Yes, stainless steel pipes can definitely be used for brewery equipment. Stainless steel is a preferred material in brewery setups due to its excellent corrosion resistance, durability, and hygienic properties. It can handle the high temperatures, acidic content, and frequent cleaning required in brewery operations, making it a reliable choice for the construction of pipes used in brewing equipment.

- Q: Are stainless steel pipes suitable for fire protection systems?

- Indeed, fire protection systems find stainless steel pipes to be a suitable option. The reason lies in the fact that stainless steel possesses remarkable resistance against corrosion, a trait of utmost importance for fire protection systems, which frequently encounter water or other corrosive substances. The ability of stainless steel pipes to endure high temperatures while preserving their structural integrity enhances their dependability for the transportation of water or other fire suppressants. Furthermore, the durability and extended lifespan of stainless steel pipes contribute to a decrease in the necessity for frequent replacements or repairs. All in all, stainless steel pipes are widely favored in fire protection systems due to their reliability, resistance to corrosion, and durability.

- Q: Can stainless steel pipes be used for solar water heating systems?

- Yes, stainless steel pipes can be used for solar water heating systems. Stainless steel is a preferred material for solar water heating systems due to its excellent corrosion resistance and durability, making it suitable for withstanding the high temperatures and harsh environmental conditions associated with solar water heating applications.

- Q: Are stainless steel pipes resistant to sea water corrosion?

- Indeed, the resistance of stainless steel pipes to corrosion caused by sea water is highly remarkable. The exceptional corrosion resistance of stainless steel is widely recognized, which makes it an optimal material for various applications, including pipes utilized in marine settings. The presence of elevated levels of chromium and nickel in stainless steel results in the formation of a protective layer on the metal's surface, effectively preventing corrosion and damage caused by exposure to sea water. Moreover, stainless steel pipes also exhibit resistance against other forms of corrosion, such as rusting and pitting, thereby further augmenting their durability and longevity in marine environments. Consequently, stainless steel pipes prove to be a dependable option for applications involving contact with sea water.

- Q: How do you pressure test stainless steel pipes?

- To ensure the integrity and safety of stainless steel pipes, it is crucial to conduct pressure testing. Below is a step-by-step guide on how to perform pressure testing on stainless steel pipes: 1. Pipe Preparation: Before initiating the pressure test, make sure the stainless steel pipes are clean and devoid of any debris or contaminants. Inspect the pipes for visible defects like cracks or leaks and repair or replace them if necessary. 2. Gathering the Necessary Equipment: You will require a pressure testing pump or equipment capable of generating the desired pressure, pressure gauges, and appropriate seals or plugs to seal the pipe ends. 3. Determining the Required Pressure: Refer to engineering specifications or relevant industry standards to determine the suitable pressure for testing the stainless steel pipes. The pressure is usually indicated in pounds per square inch (psi). 4. Sealing the Pipe Ends: Use suitable seals or plugs to securely seal all the ends of the stainless steel pipes. This will prevent any leakage during the pressure test. 5. Connecting the Pressure Testing Equipment: Connect the pressure testing pump or equipment to one end of the pipe using a pressure gauge to accurately monitor the pressure. Ensure that the connections are tight and leak-proof. 6. Applying Pressure Gradually: Gradually increase the pressure in the stainless steel pipes using the pressure testing pump or equipment. Keep a close eye on the pressure gauge and ensure it reaches and stabilizes at the desired testing pressure. This gradual process avoids sudden pressure surges that could potentially damage the pipes. 7. Maintaining the Pressure: Maintain the pressure at the desired level for a specified duration as recommended by engineering specifications or standards. The duration can vary from a few minutes to several hours depending on the application and requirements. 8. Leak Inspection: While maintaining the pressure, carefully inspect the stainless steel pipes for any signs of leakage. Look for visible leaks, listen for hissing sounds, or use leak-detection solution or soapy water to identify any escaping air or bubbles. If leaks are detected, halt the pressure test and address the issue before proceeding. 9. Releasing the Pressure: Once the pressure test is completed, gradually release the pressure from the stainless steel pipes using the pressure testing pump or equipment. Be cautious while releasing the pressure to prevent sudden decompression that could potentially damage the pipes. 10. Evaluating the Results: After the pressure test, inspect the stainless steel pipes again to ensure no new leaks or defects have emerged. If the pipes have successfully passed the pressure test without any issues, they can be considered safe and suitable for their intended application. It is important to note that pressure testing stainless steel pipes should only be carried out by qualified personnel following industry standards and guidelines to ensure accuracy and safety.

- Q: What's the difference between cold drawn steel tube and hot rolled steel tube?

- Cold drawn steel tube is a kind of precision cold drawn seamless pipe used for mechanical structure and hydraulic equipment with high dimensional accuracy and good surface finish. The use of precision seamless tube manufacturing machinery structure or hydraulic equipment, etc., can greatly save the working hours of mechanical processing, improve material utilization, at the same time help improve product quality.

- Q: Can stainless steel pipes be used for gas pipelines?

- Indeed, gas pipelines can utilize stainless steel pipes. Stainless steel, renowned for its exceptional durability and resistance to corrosion, proves to be an ideal material for transporting a wide range of gases, including natural gas and propane. Moreover, stainless steel pipes possess remarkable tensile strength, enabling them to endure the demanding conditions of high pressure and temperature frequently encountered in gas pipelines. Furthermore, stainless steel demonstrates non-reactivity, thereby guaranteeing the integrity and safety of the pipeline system by preventing any interaction with the transported gases. Ultimately, with its strength, corrosion resistance, and capability to withstand high-pressure environments, stainless steel pipes emerge as a dependable choice for gas pipelines.

- Q: Are stainless steel tubes and galvanized steel tubes the same?

- Galvanized steel pipe is common steel pipe, and then the surface coated with a layer of zinc coating, in order to prevent rust, as long as the surface layer is ground, it will rust.

- Q: Can stainless steel pipes be lined with polyethylene?

- Yes, stainless steel pipes can be lined with polyethylene. Lining stainless steel pipes with polyethylene is a common practice in various industries, including oil and gas, chemical processing, and water distribution. The polyethylene lining provides several benefits such as corrosion resistance, increased flow capacity, reduced friction, and improved resistance to chemicals. This lining process involves inserting a polyethylene liner into the stainless steel pipe and then heating and expanding it to create a tight fit. This lining technique is effective for protecting the stainless steel pipes from corrosion and extending their lifespan.

Send your message to us

Stainless steel welded pipe variety specification

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords