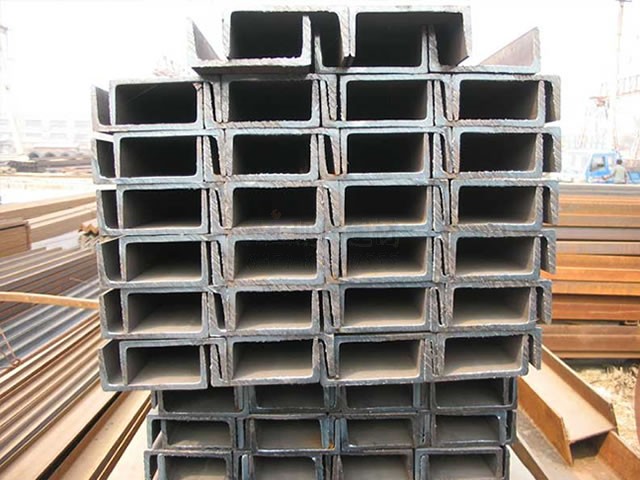

Stainless Steel U-Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Stainless Steel U-Channels at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Stainless Steel U-Channels are ideal for structural applications and general fabricating, as well as transportation and engineering.

Product Advantages:

OKorder's Steel Channels are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (15-30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Lighter than concrete

· Professional Service

· Competitive pricing

Product Specifications:

Process: Cold drawn, hot rolled

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: 201, 304, 316, 316L, 321

Height: 90 – 400mm

Thickness: 0.4 – 4mm

Length: 6m, as per customer request

Max Dimensions: 40*20*200*100mm

Surface: Bright, polished, peeled

Place of Origin: Tianjin, China

MOQ: 1 ton

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: Are stainless steel channels suitable for tank supports?

- Yes, stainless steel channels are suitable for tank supports. Stainless steel is known for its durability, corrosion resistance, and high strength, making it an excellent choice for supporting heavy loads such as tanks. Stainless steel channels provide a strong and stable framework for tank supports, ensuring the tank remains securely in place and can withstand the weight and pressure it holds. Additionally, stainless steel channels are resistant to rust and other forms of corrosion, which is crucial for tank supports as they are often exposed to moisture and chemicals. This makes stainless steel channels a reliable and long-lasting option for tank supports in various industries such as manufacturing, water treatment, and chemical processing.

- Q: Are stainless steel channels suitable for earthquake-resistant construction?

- Stainless steel channels are indeed suitable for earthquake-resistant construction. The reason lies in the exceptional qualities of stainless steel, such as its high strength-to-weight ratio, corrosion resistance, and ductility, which make it an ideal material for buildings in seismic zones. When an earthquake occurs, stainless steel channels possess the capability to absorb and dissipate energy, effectively reducing the impact of seismic forces on the structure. Additionally, its ductility allows it to deform without fracturing, ensuring the building's integrity remains intact even during intense shaking. Moreover, the corrosion resistance of stainless steel is a significant advantage, especially in areas prone to earthquakes where moisture and harsh environmental conditions can pose a threat to buildings. This resistance ensures the long-term durability and structural integrity of the channels. Furthermore, stainless steel channels offer ease in fabrication and installation, granting designers and engineers the flexibility to optimize the structural system to withstand earthquake loads and create buildings that meet the required seismic performance standards. In summary, the combination of high strength, ductility, corrosion resistance, and ease of fabrication renders stainless steel channels an appropriate choice for earthquake-resistant construction. By using these channels, structures in seismic zones can gain enhanced safety and resilience.

- Q: What are the dimensions and sizes of stainless steel channels?

- The dimensions and sizes of stainless steel channels can vary depending on the specific requirements and industry standards. However, commonly used sizes for stainless steel channels range from 1 inch to 8 inches in height, with widths ranging from 1/2 inch to 3 inches. The thickness can also vary, typically ranging from 1/8 inch to 1/2 inch. These dimensions allow for a wide range of applications across various industries.

- Q: Can stainless steel channels be used for electrical wiring management?

- Yes, stainless steel channels can be used for electrical wiring management. Stainless steel channels are durable, resistant to corrosion, and can provide effective protection and organization for electrical wiring systems. They are commonly used in industrial and commercial settings where there is a need for reliable and efficient electrical wiring management.

- Q: Are stainless steel channels suitable for use in the automotive industry?

- Yes, stainless steel channels are suitable for use in the automotive industry. Stainless steel is known for its excellent corrosion resistance, high strength, and durability, making it an ideal material for various automotive applications. Stainless steel channels can be used for structural components, such as frames, chassis, and body supports, as well as for decorative purposes, such as trims and moldings. Stainless steel channels provide the necessary strength and stability, even in harsh environments, ensuring the longevity and safety of automotive vehicles. Additionally, stainless steel is easy to clean and maintain, making it a practical choice for the automotive industry.

- Q: Can stainless steel channels be used for agricultural or farming structures?

- Yes, stainless steel channels can be used for agricultural or farming structures. Stainless steel is known for its durability, corrosion resistance, and strength, making it suitable for various applications in the agricultural industry. It can be used for constructing barns, poultry houses, livestock enclosures, storage sheds, and other farm structures that require long-lasting and reliable materials. Stainless steel channels provide structural support and can withstand harsh environmental conditions, making them a suitable choice for agricultural purposes.

- Q: How do stainless steel channels compare to wooden or plastic channels?

- Stainless steel channels offer several advantages over wooden or plastic channels. Firstly, stainless steel is highly durable and resistant to corrosion, ensuring long-term use without deterioration. Additionally, stainless steel channels provide a higher load-bearing capacity, making them suitable for heavy-duty applications. They are also easier to clean and maintain, as they are non-porous and impervious to moisture, unlike wood or plastic. Finally, stainless steel channels have a sleek and modern appearance, making them a preferred choice for architectural and design purposes.

- Q: How do you determine the appropriate size of a stainless steel channel for a specific application?

- Determining the suitable size of a stainless steel channel for a specific application involves taking into account various elements. Below are the essential actions to establish the appropriate size: 1. Determine the load requirements: The initial step involves identifying the maximum load that the stainless steel channel must support. This encompasses both the static load (the weight of the material being supported) and the dynamic load (additional forces or vibrations). It is crucial to comprehend the distribution and magnitude of the load in order to select the right size. 2. Consider the properties of the material: Stainless steel channels are available in different grades, each possessing distinct mechanical properties. Take into consideration the specific grade of stainless steel required for the application, as it affects the strength and durability of the channel. Ensure that the chosen grade can withstand the environmental conditions and any corrosive agents present. 3. Assess the dimensions and shape: Evaluate the dimensions and shape of the application to determine the necessary size of the stainless steel channel. Take into account the length, width, and height required to achieve the desired strength and stability. Additionally, analyze the cross-sectional shape of the channel (C, U, or customized) to ensure it provides sufficient support and functionality. 4. Consult applicable design codes and standards: Refer to relevant design codes and standards that apply to the specific application or industry. These codes offer guidelines and safety factors to aid in determining the appropriate size of the stainless steel channel. Examples include the American Institute of Steel Construction (AISC) Manual or Eurocode standards. 5. Perform structural analysis: Utilize structural analysis techniques, such as finite element analysis (FEA), to simulate the loading conditions and evaluate the structural performance of the channel. This analysis assists in determining the appropriate size by considering factors such as stress distribution, deflection, and buckling. 6. Seek professional guidance: If unsure or dealing with complex applications, it is advisable to seek advice from an experienced structural engineer or a stainless steel specialist. They can offer valuable insights and expertise in selecting the suitable size of a stainless steel channel, considering all the relevant factors mentioned above. By following these steps and considering all the necessary elements, one can determine the appropriate size of a stainless steel channel for a specific application, ensuring optimal performance, safety, and longevity.

- Q: Can stainless steel channels be used for framing or support structures in corrosive environments?

- Yes, stainless steel channels can be used for framing or support structures in corrosive environments. Stainless steel is known for its excellent corrosion resistance properties, which makes it suitable for use in environments where there is exposure to moisture, chemicals, or saltwater. The chromium content in stainless steel forms a passive oxide layer on the surface, which acts as a protective barrier against corrosion. This oxide layer is self-healing and helps to prevent further corrosion. Additionally, stainless steel channels are available in various grades, with each grade offering different degrees of corrosion resistance. For highly corrosive environments, such as marine or industrial settings, it is recommended to use stainless steel channels with higher levels of corrosion resistance, such as grades 316 or 2205. These grades have additional alloying elements like molybdenum and nitrogen, which further enhance their corrosion resistance properties. Overall, stainless steel channels are an excellent choice for framing or support structures in corrosive environments due to their durability, longevity, and ability to withstand corrosion.

- Q: Are stainless steel channels suitable for flooring or grating systems?

- Depending on the particular needs and circumstances of the project, stainless steel channels may be a suitable option for flooring or grating systems. Stainless steel is known for its durability, resistance to corrosion, and excellent strength-to-weight ratio, which makes it a popular choice for various industrial and commercial applications. In flooring systems, stainless steel channels can be used to offer structural support and create a stable walking surface. They are ideal for areas that require a high load-bearing capacity, such as factories, warehouses, or outdoor platforms. Stainless steel channels can withstand heavy foot traffic and effectively distribute weight, ensuring the safety and longevity of the flooring system. Similarly, in grating systems, stainless steel channels can be utilized to support and secure grating panels. Stainless steel's resistance to corrosion and ability to withstand harsh environments make it suitable for applications that involve frequent exposure to water, chemicals, or extreme temperatures. Stainless steel channels can be used in industrial settings, including wastewater treatment plants, oil refineries, or chemical processing facilities, where a durable and long-lasting grating system is necessary. However, it is crucial to consider the specific requirements and conditions of the project before determining the suitability of stainless steel channels for flooring or grating systems. Factors such as load capacity, environmental conditions, and maintenance needs should be taken into account to ensure optimal performance and longevity of the system. Seeking advice from a professional engineer or supplier specializing in stainless steel channels can provide valuable guidance and help in making the right choice for the specific project.

Send your message to us

Stainless Steel U-Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords