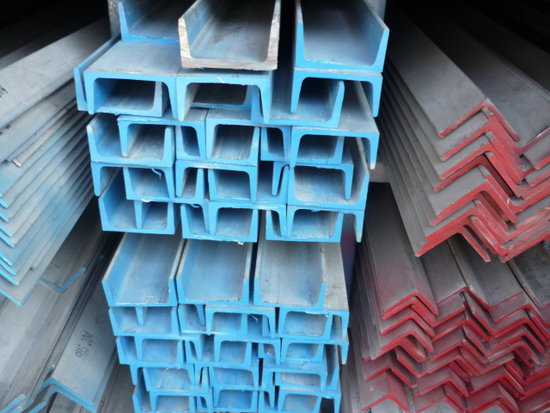

304 Stainless Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Channel

1.Size: 3mm to 24mm Thickness

2.Material:SUS201,202,301,304,304L,316,316L ,321 etc.

3.Length: 4m to 6m,or according to the customer's requirement

4.Standard: AISI,JIS,GB,DIN

5.Finish: Cold Drawn ,hot rolled & Polishing

6.Testing: Each heat number and batch must be tested for both chemical and mechanical properties

7.Application: Produce screw and nut, engine parts, indoor and outdoor decorating,etc.

|

Size (mm) |

Thickness (mm) | ||||||||

|

H×B |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

12 |

|

Mass (Kg/m) | |||||||||

|

40×20 |

1.79 |

|

|

|

|

|

|

|

|

|

50×25 |

2.27 |

|

|

|

|

|

|

|

|

|

60×30 |

2.74 |

3.56 |

4.37 |

5.12 |

|

|

|

|

|

|

70×35 |

3.23 |

4.21 |

5.17 |

6.08 |

|

|

|

|

|

|

80×40 |

3.71 |

4.84 |

5.96 |

7.03 |

|

|

|

|

|

|

90×45 |

4.25 |

5.55 |

6.83 |

8.05 |

|

|

|

|

|

|

100×50 |

4.73 |

6.18 |

7.62 |

8.98 |

10.3 |

11.7 |

13 |

41.2 |

|

|

120×60 |

|

|

9.2 |

10.9 |

12.6 |

14.2 |

|

|

|

|

130×65 |

|

|

10.1 |

11.9 |

13.8 |

15.5 |

17.3 |

19.1 |

|

|

140×70 |

|

|

|

12.9 |

14.9 |

16.8 |

18.8 |

20.7 |

|

|

150×75 |

|

|

|

13.9 |

16 |

18.1 |

20.2 |

22.2 |

26.3 |

|

160×80 |

|

|

|

14.8 |

17.1 |

19.3 |

21.6 |

23.8 |

28.1 |

|

180×90 |

|

|

|

16.7 |

19.4 |

22 |

24.5 |

27 |

32 |

|

200×100 |

|

|

|

18.6 |

21.6 |

24.5 |

27.4 |

30.2 |

35.8 |

- Q: Can stainless steel channels be used for suspended ceiling systems?

- Yes, stainless steel channels can be used for suspended ceiling systems. Stainless steel is a high-quality and durable material that offers several advantages for suspended ceilings. It is resistant to corrosion, which makes it ideal for areas with high moisture, such as kitchens or bathrooms. Stainless steel channels also have a sleek and modern appearance, adding an aesthetic appeal to the ceiling system. Additionally, stainless steel channels are easy to install and maintain, making them a practical choice for suspended ceilings in various settings, including commercial, industrial, and residential buildings.

- Q: Are stainless steel channels available in different grades?

- Yes, stainless steel channels are available in different grades. Stainless steel is a versatile material that contains various alloying elements, which determine the grade and its properties. The most common grades of stainless steel channels include 304 and 316. Grade 304 is a general-purpose stainless steel that is widely used due to its excellent corrosion resistance and low maintenance requirements. Grade 316, on the other hand, is known for its superior corrosion resistance, especially in harsh environments or applications involving exposure to chemicals or saltwater. Other grades, such as 310, 321, and 430, are also available and each offers specific properties to suit different applications. It is important to consider the specific requirements of your project and consult with a stainless steel supplier to determine the most suitable grade for your needs.

- Q: Can stainless steel channels be used in the construction of storage racks?

- Stainless steel channels are indeed applicable in the construction of storage racks. The material boasts durability and resistance against corrosion, rendering it a perfect choice for storage rack usage. Its exceptional strength and stability make it apt for bearing heavy loads. Moreover, stainless steel channels can be effortlessly crafted and tailored to cater to the precise demands of storage rack design. They exhibit remarkable resilience against moisture, chemicals, and temperature changes, thus guaranteeing the enduring dependability of storage racks.

- Q: What are the load distribution capabilities of stainless steel channels?

- Stainless steel channels have excellent load distribution capabilities due to their inherent strength and durability. They can effectively distribute loads across their surface, making them suitable for various applications where structural support is required.

- Q: Can stainless steel channels be used for railway infrastructure?

- Yes, stainless steel channels can be used for railway infrastructure. Stainless steel is known for its durability, corrosion resistance, and strength, making it suitable for various applications in the railway industry, including tracks, bridges, and platforms. Additionally, stainless steel's low maintenance requirements and long lifespan make it a cost-effective choice for railway infrastructure.

- Q: What is the thermal conductivity of stainless steel channels?

- The thermal conductivity of stainless steel channels can vary depending on the specific grade of stainless steel and its composition. Generally, stainless steel is known for its relatively low thermal conductivity compared to other metals such as copper or aluminum. However, within the range of stainless steel alloys, there can be variations in thermal conductivity. For example, austenitic stainless steel, which is commonly used in channels, typically has lower thermal conductivity compared to ferritic or martensitic stainless steel. The thermal conductivity of stainless steel channels can also be affected by factors such as temperature, surface finish, and any insulating materials present. In general, stainless steel channels are not the most efficient conductors of heat, but they can still effectively transfer heat if designed and used appropriately. If high thermal conductivity is required for a specific application, it is advisable to consult with the manufacturer or refer to specific material data sheets to determine the thermal conductivity of the specific stainless steel alloy being used.

- Q: Can stainless steel channels be used for electrical applications?

- Indeed, electrical applications can make use of stainless steel channels. Renowned for its exceptional corrosion resistance, durability, and impressive strength-to-weight ratio, stainless steel proves itself suitable for diverse electrical purposes. These channels serve as cable trays, supports for electrical cables, conduits, and junction boxes, offering a robust and dependable framework for electrical systems, thereby guaranteeing the safety and efficiency of the installation. Furthermore, stainless steel channels find utility in hostile environments where corrosion or chemical exposure poses a concern.

- Q: How are stainless steel channels used in construction?

- Stainless steel channels are widely used in construction for various purposes due to their unique properties. These channels, also known as C-channels or U-channels, are versatile structural components that provide strength, support, and stability to different construction applications. One common application of stainless steel channels in construction is in the framing of buildings and structures. They are used as primary components in the construction of walls, roofs, and floors. Stainless steel channels offer excellent load-bearing capacity, making them suitable for withstanding heavy loads and supporting the weight of the structure. Additionally, stainless steel channels are often utilized as support beams and braces in construction projects. They are used to reinforce and strengthen the framework, ensuring the stability and structural integrity of the building. These channels are particularly useful in areas prone to seismic activities or high wind loads, as they offer resistance against these forces. Another way stainless steel channels are used in construction is for the installation of electrical and plumbing systems. They act as conduits, providing a secure and organized pathway for electrical wires, cables, and plumbing pipes. Stainless steel channels are corrosion-resistant, making them ideal for carrying water or other liquids without the risk of rust or degradation. Moreover, stainless steel channels find applications in architectural designs. They are used to create decorative elements such as handrails, balustrades, and staircases. Stainless steel channels offer an aesthetically pleasing appearance and can be easily customized to fit various design requirements. In summary, stainless steel channels play a vital role in construction by providing structural support, reinforcing frameworks, facilitating the installation of electrical and plumbing systems, and adding aesthetic appeal. Their durability, corrosion resistance, and versatility make them a popular choice in the construction industry.

- Q: What are the insulation properties of stainless steel channels?

- Stainless steel channels have relatively low insulation properties compared to other materials commonly used for insulation purposes. However, stainless steel does have some thermal resistance due to its low thermal conductivity. Therefore, it can provide a certain level of insulation, but it is not as effective as materials specifically designed for insulation, such as foam or fiberglass.

- Q: How do stainless steel channels compare to galvanized channels?

- Stainless steel channels are generally considered to be more durable and resistant to corrosion compared to galvanized channels. Stainless steel channels also have a higher strength-to-weight ratio and are often preferred for applications that require higher load-bearing capabilities. Additionally, stainless steel channels offer a more aesthetically pleasing finish and can withstand extreme temperature variations better than galvanized channels.

Send your message to us

304 Stainless Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords