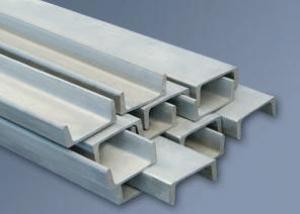

SUS304 Stainless Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Ton Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Channel

1.Size: 3mm to 24mm Thickness

2.Material:SUS201,202,301,304,304L,316,316L ,321 etc.

3.Length: 4m to 6m,or according to the customer's requirement

4.Standard: AISI,JIS,GB,DIN

5.Finish: Cold Drawn ,hot rolled & Polishing

6.Testing: Each heat number and batch must be tested for both chemical and mechanical properties

7.Application: Produce screw and nut, engine parts, indoor and outdoor decorating,etc.

|

Size (mm) |

Thickness (mm) | ||||||||

|

H×B |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

12 |

|

Mass (Kg/m) | |||||||||

|

40×20 |

1.79 |

|

|

|

|

|

|

|

|

|

50×25 |

2.27 |

|

|

|

|

|

|

|

|

|

60×30 |

2.74 |

3.56 |

4.37 |

5.12 |

|

|

|

|

|

|

70×35 |

3.23 |

4.21 |

5.17 |

6.08 |

|

|

|

|

|

|

80×40 |

3.71 |

4.84 |

5.96 |

7.03 |

|

|

|

|

|

|

90×45 |

4.25 |

5.55 |

6.83 |

8.05 |

|

|

|

|

|

|

100×50 |

4.73 |

6.18 |

7.62 |

8.98 |

10.3 |

11.7 |

13 |

41.2 |

|

|

120×60 |

|

|

9.2 |

10.9 |

12.6 |

14.2 |

|

|

|

|

130×65 |

|

|

10.1 |

11.9 |

13.8 |

15.5 |

17.3 |

19.1 |

|

|

140×70 |

|

|

|

12.9 |

14.9 |

16.8 |

18.8 |

20.7 |

|

|

150×75 |

|

|

|

13.9 |

16 |

18.1 |

20.2 |

22.2 |

26.3 |

|

160×80 |

|

|

|

14.8 |

17.1 |

19.3 |

21.6 |

23.8 |

28.1 |

|

180×90 |

|

|

|

16.7 |

19.4 |

22 |

24.5 |

27 |

32 |

|

200×100 |

|

|

|

18.6 |

21.6 |

24.5 |

27.4 |

30.2 |

35.8 |

- Q: Do stainless steel channels have any electrical conductivity?

- Indeed, electrical conductivity is present in stainless steel channels. Although stainless steel falls short in conductivity compared to metals such as copper or aluminum, it still possesses a certain level of electrical conduction. The electrical conductivity of stainless steel channels may fluctuate due to factors like the composition of the alloy and the surface finish. It is worth highlighting that stainless steel is commonly preferred for its resistance to corrosion and its mechanical properties, rather than its electrical conductivity.

- Q: Are stainless steel channels suitable for hygienic applications?

- Yes, stainless steel channels are highly suitable for hygienic applications. Stainless steel is known for its excellent corrosion resistance, durability, and low maintenance requirements, making it an ideal choice for industries that require high levels of cleanliness and sanitation. Stainless steel channels have a smooth surface finish, which makes them easy to clean and disinfect, preventing the growth of bacteria, mold, and other contaminants. This is especially important in industries such as food and beverage processing, pharmaceuticals, healthcare, and laboratories, where maintaining strict hygiene standards is crucial. Additionally, stainless steel is resistant to chemicals, making it suitable for applications where harsh cleaning agents or disinfectants are used. It is also non-porous, meaning it does not absorb or retain moisture, which further enhances its hygienic properties. Stainless steel channels are also durable and long-lasting, allowing them to withstand high traffic areas and heavy loads without compromising their hygienic properties. They are resistant to impact, abrasion, and temperature variations, ensuring their suitability for a wide range of hygienic applications. In conclusion, stainless steel channels are an excellent choice for hygienic applications due to their corrosion resistance, durability, ease of cleaning, and resistance to chemicals. They are widely used in industries where maintaining high levels of cleanliness and sanitation is essential.

- Q: Are stainless steel channels easy to transport?

- Stainless steel channels, by and large, are uncomplicated to transport. Their reputation for strength and durability makes them a trustworthy choice for transportation needs. Moreover, stainless steel channels are frequently crafted in diverse lengths and sizes, facilitating effortless handling and maneuverability during transportation. Furthermore, stainless steel's resistance to corrosion and rust guarantees that the channels will remain in optimal condition, even when subjected to varying weather conditions while being transported. All in all, the attributes of stainless steel render it an ideal material for the effortless and trouble-free transportation of channels.

- Q: What are the load-bearing capabilities of stainless steel channels?

- Various factors, such as the type of stainless steel, channel dimensions and geometry, and the application, contribute to the load-bearing capabilities of stainless steel channels. Stainless steel channels possess strength and durability, making them suitable for a wide range of load-bearing applications. Grade 304 or 316 stainless steel is commonly used for channels due to their corrosion resistance and structural integrity. To determine the load-bearing capacity of stainless steel channels, one must consider the material's yield strength, which is the maximum stress it can withstand before permanent deformation occurs. Stainless steel channels typically have high yield strengths, ranging from 30,000 to 90,000 psi, depending on the grade and thickness of the material. However, it is crucial to note that the material alone does not determine the load-bearing capabilities. The design, installation, and support structure of the channel play significant roles in determining its ultimate load-bearing capacity. Factors like the number and spacing of fasteners, distance between supports, and load distribution all require careful consideration. In general, stainless steel channels can support substantial loads, ranging from light to heavy, depending on the specific application and design. They are commonly employed in construction, infrastructure projects, and industrial applications where durability and strength are essential. To accurately determine the load-bearing capabilities of stainless steel channels for a specific application, it is advisable to consult relevant engineering standards, guidelines, or seek the assistance of a professional engineer. They can provide detailed calculations and recommendations based on the project's specific requirements and conditions.

- Q: Can stainless steel channels be used for shelving or storage racks?

- Certainly, shelving or storage racks can make use of stainless steel channels. This material, known for its durability and resistance to corrosion, is well-suited for a range of applications, including shelving and storage racks. By providing structural support and stability, stainless steel channels ensure that these racks can withstand heavy loads and maintain stability over time. Moreover, stainless steel's appealing appearance and ease of cleaning make it an excellent choice for environments where hygiene and aesthetics are imperative, such as commercial kitchens, hospitals, or laboratories. In conclusion, stainless steel channels offer both functionality and longevity, making them an optimal option for shelving or storage racks.

- Q: Are stainless steel channels resistant to staining from chemicals?

- Yes, stainless steel channels are highly resistant to staining from chemicals. Stainless steel is known for its excellent corrosion resistance properties, which make it resistant to the damaging effects of various chemicals. It has a protective oxide layer on its surface that prevents the penetration of chemicals, thus reducing the risk of staining. Additionally, stainless steel channels are often made with specific grades that are more resistant to certain types of chemicals, ensuring even higher resistance to staining. Overall, stainless steel channels are a durable and reliable choice for applications where exposure to chemicals is a concern.

- Q: What are the typical applications of stainless steel channels?

- Stainless steel channels are commonly used in various applications such as construction, architectural designs, infrastructure projects, manufacturing processes, and the automotive industry. They are particularly useful in providing structural support, reinforcement, and framing for buildings, bridges, and machinery. Additionally, stainless steel channels are also utilized in the production of furniture, handrails, shelving units, and electrical enclosures due to their durability, corrosion resistance, and aesthetic appeal.

- Q: What are the different surface colors available for stainless steel channels?

- Stainless steel channels are available in a variety of surface colors to suit different aesthetic preferences and applications. The most common surface colors for stainless steel channels include: 1. Brushed or satin finish: This is the most popular surface color for stainless steel channels. It features a dull, matte appearance created by brushing the surface with abrasive material. The brushed finish is known for its durability, resistance to fingerprints, and easy maintenance. 2. Mirror finish: Also known as a polished finish, this surface color offers a reflective and shiny appearance. Achieved through polishing the stainless steel surface to a high gloss, the mirror finish is often chosen for its aesthetic appeal and ability to enhance the overall look of a space. 3. Matte finish: This surface color provides a smooth, non-reflective appearance. It is achieved by applying a coating or using a chemical treatment to create a uniform, dull surface. The matte finish is commonly used in industrial or commercial settings where a subdued appearance is desired. 4. Colored finishes: Stainless steel channels can also be coated with various colors to match specific design requirements. These colored finishes are achieved through powder coating or PVD (Physical Vapor Deposition) processes, where a thin layer of color is applied to the stainless steel surface. Popular colored finishes include black, gold, bronze, and copper. It is important to note that the availability of surface colors may vary depending on the manufacturer and specific product line. Consulting with a supplier or manufacturer can provide more detailed information on the range of surface colors available for stainless steel channels.

- Q: Can stainless steel channels be used in the construction of staircases?

- Yes, stainless steel channels can be used in the construction of staircases. Stainless steel is a durable and corrosion-resistant material, making it suitable for both indoor and outdoor staircases. It offers strength and stability, while also providing a modern and sleek aesthetic. Additionally, stainless steel channels can be easily fabricated and customized to meet specific design requirements for staircases.

- Q: What are the insulation properties of stainless steel channels?

- Due to their high thermal conductivity, stainless steel channels typically exhibit inadequate insulation properties. The efficiency of stainless steel in conducting heat renders it unsuitable for insulating purposes. In contrast to fiberglass or foam, stainless steel channels fail to effectively obstruct the transmission of heat or cold. Consequently, for those prioritizing insulation, it is advisable to opt for alternative materials offering superior insulation characteristics.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$8 million |

| Main Markets | East Asia, Middle East, West Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | above 50 people |

| Language Spoken: | English, Chinese, Arabic |

| b) Factory Information | |

| Factory Size: | about 15000 square meter |

| No. of Production Lines | above 4 |

| Contract Manufacturing | OEM Service Offered,Design Service Offered |

| Product Price Range | Average |

Send your message to us

SUS304 Stainless Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Ton Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords