Best Quality for Stainless Steel Channels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 500 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

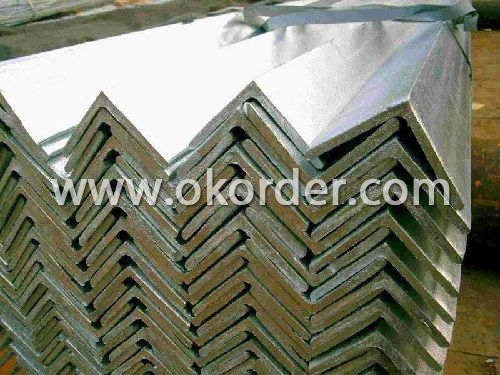

Stainless Steel Channels

General Information of Stainless Steel Channels

Stainless Steel Channel, is ideal for all applications where greater strength and superior corrosion resistance is required. Stainless Channel has a durable dull, mill finish that is widely used for all types of fabrication projects that are exposed to the elements -chemical, acidic, fresh water, and salt water environments.

The standard length for most size channel is 12’-14’ random lengths, but lengths are available in some sizes up to 20’ and longer. Finishes on channel can vary and include cold drawn, center less ground, smooth turned, rough turned, turned ground and polished, and HRAP.

1. We will custom saw cut to length

2. DEFARS or domestic material available in many sizes

3. Polishing services are available

Specification of Stainless Steel Channels

Product Name | Stainless Steel Channel |

Standard | JIS, ASTM, GB, DIN, EN, AISI. |

Grade | 301,302,303,304,304L,305,309S,310S,316,316L,317,317L,321,347 631. |

Diameter | 75x30x6mm many other sizes can be done |

Length | 1m~6m |

Package Detail | Export standard package, bundled or be required. The inner size of container is below: 20ft GP: 5.9m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM |

Delivery Time | Normally according to the order quantity or upon negotiation. |

Payment Terms | L/C, T/T. |

Application | Food stuff, gas, metallurgy, biology, electron, chemical, petroleum, boilers, nuclear, energy, construction field, ships building industry, war and electricity industry, boiler heat exchanger, machi-nery and hardware fields and medical equipment, fertilizer, e-tc. |

Contact | Our products are very popular because of high-quality and reasonable prices. If you are interested in any of our products, ple-ase feel free to contact us for more information. |

- Q: Can stainless steel channels be used for railings or balustrades?

- Yes, stainless steel channels can be used for railings or balustrades. Stainless steel is a popular material choice for railings and balustrades due to its durability, strength, and aesthetic appeal. Stainless steel channels are capable of providing structural support and can be easily integrated into railing or balustrade systems. They can be used to create a sleek and modern look, and they are resistant to corrosion, making them suitable for both indoor and outdoor applications. Additionally, stainless steel channels can be customized to fit specific design requirements, allowing for a wide range of creative possibilities in railing and balustrade installations.

- Q: What are the vibration damping properties of stainless steel channels?

- Stainless steel channels have excellent vibration damping properties. The material's high density and stiffness effectively absorb and dissipate vibrations, reducing noise and minimizing the transmission of vibrations to surrounding structures. Additionally, stainless steel's corrosion resistance ensures long-term performance in various environments, making it a suitable choice for applications requiring vibration damping capabilities.

- Q: Can stainless steel channels be used in outdoor furniture?

- Yes, stainless steel channels can be used in outdoor furniture. Stainless steel is highly resistant to corrosion, making it an excellent choice for outdoor applications where furniture is exposed to moisture and varying weather conditions. Stainless steel channels offer structural strength and durability, making them ideal for supporting the weight of outdoor furniture. Additionally, stainless steel has a sleek and modern appearance, which can enhance the overall aesthetic of outdoor furniture.

- Q: Do stainless steel channels require any protective coatings?

- Protective coatings are not always necessary for stainless steel channels because stainless steel itself is highly resistant to corrosion and rust. The main advantage of stainless steel is that it forms a passive protective layer on its surface, preventing further oxidation and corrosion. However, there are situations and environments where protective coatings may be necessary for stainless steel channels. For instance, if the channels are exposed to extremely corrosive chemicals or harsh weather conditions, applying a protective coating can provide an additional defense against corrosion. Moreover, in industries like food processing and pharmaceuticals where hygiene is crucial, a protective coating may be applied to ensure easy cleaning and resistance to bacterial growth in the channels. Ultimately, the decision to use protective coatings on stainless steel channels depends on the specific application and the desired level of corrosion resistance.

- Q: Can stainless steel channels be used for equipment or machinery support structures?

- Yes, stainless steel channels can be used for equipment or machinery support structures. Stainless steel is a strong and durable material that provides excellent resistance to corrosion, making it suitable for use in various environments. Stainless steel channels are often used in construction and industrial applications due to their structural integrity and ability to withstand heavy loads. They can be easily fabricated and welded to create sturdy support structures for equipment or machinery. Additionally, stainless steel channels offer aesthetic appeal with their sleek and modern finish. Overall, stainless steel channels are a reliable choice for supporting equipment or machinery in different industries.

- Q: Are stainless steel channels suitable for use in harsh chemical environments?

- Stainless steel channels are indeed appropriate for harsh chemical environments due to their exceptional resistance to corrosion. Known for its excellent corrosion resistance properties, stainless steel effectively withstands various chemicals. It remains unaffected by acids, alkalis, solvents, and other corrosive substances commonly present in such environments. Moreover, stainless steel channels provide exceptional strength and durability, rendering them perfect for withstanding extreme conditions within these environments. Furthermore, their easy cleaning and maintenance ensure their longevity, even in the harshest chemical settings.

- Q: Can stainless steel channels be used in pharmaceutical or laboratory settings?

- Pharmaceutical or laboratory settings can utilize stainless steel channels, as they possess exceptional corrosion resistance, durability, and cleaning convenience. These industries prefer stainless steel due to its ability to construct equipment, fixtures, and storage systems. Stainless steel channels can withstand chemicals, moisture, and temperature changes, making them suitable for storing, transporting, and processing diverse substances and materials. Moreover, their smooth, non-porous surface prevents the accumulation of bacteria and other contaminants, ensuring a clean and hygienic environment in pharmaceutical and laboratory settings.

- Q: How do stainless steel channels perform in vibration-prone environments?

- Due to their excellent mechanical properties and inherent resistance to vibration, stainless steel channels are highly suitable for environments prone to vibrations. The unique composition and structure of stainless steel make it the preferred choice for applications where vibration is a concern. Stainless steel channels possess a high tensile strength, enabling them to withstand the dynamic forces generated by vibrations without deforming or breaking. This property ensures their durability and reliability in environments with constant movement or oscillation. Moreover, stainless steel exhibits excellent resistance to corrosion and oxidation, enhancing its performance in vibration-prone environments. Unlike other materials, stainless steel does not easily corrode, even when exposed to moisture, chemicals, or harsh weather conditions. This corrosion resistance ensures that the channels maintain their structural integrity and functionality over time, even in demanding environments. Another advantage of stainless steel channels in vibration-prone environments is their ability to absorb and dampen vibrations. With their high density and stiffness, stainless steel channels effectively dampen vibrations, reducing their transmission to other parts of the structure or equipment. This minimizes the risk of damage and increases the overall stability of the system. Furthermore, stainless steel channels offer versatility in design and fabrication. They can be customized to meet specific requirements, allowing for precise fitting and integration into various applications. This flexibility enables engineers to optimize the performance of stainless steel channels in vibration-prone environments, ensuring optimal functionality and efficiency. In conclusion, stainless steel channels demonstrate exceptional performance in vibration-prone environments. Their high tensile strength, corrosion resistance, vibration-dampening capabilities, and versatility make them a reliable and long-lasting choice for applications such as industrial machinery, construction, transportation, and infrastructure projects.

- Q: Are stainless steel channels magnetic?

- No, stainless steel channels are not magnetic. While stainless steel does contain a small amount of iron, the addition of other elements such as chromium and nickel in the alloy composition creates a protective layer on the surface, known as a passive layer. This passive layer makes stainless steel channels non-magnetic.

- Q: Can stainless steel channels be used for water treatment facilities?

- Indeed, the utilization of stainless steel channels in water treatment facilities is feasible. Due to its exceptional durability and resistance to corrosion, stainless steel proves to be an optimal choice for environments involving water. Its capability to endure diverse chemicals, elevated temperatures, and severe conditions commonly encountered in water treatment facilities further solidifies its suitability. Stainless steel channels find widespread application in the fabrication of tanks, pipelines, and various other elements within water treatment plants. Furthermore, the smooth surface of stainless steel impedes the buildup of bacteria and other microorganisms, thereby guaranteeing the cleanliness and safety of the treated water.

1. Manufacturer Overview

| Location | Zhejiang,China |

| Year Established | 2000 |

| Annual Output Value | Above US$8.3 Million |

| Main Markets | Europe, America |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 30 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 7 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality for Stainless Steel Channels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 500 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords