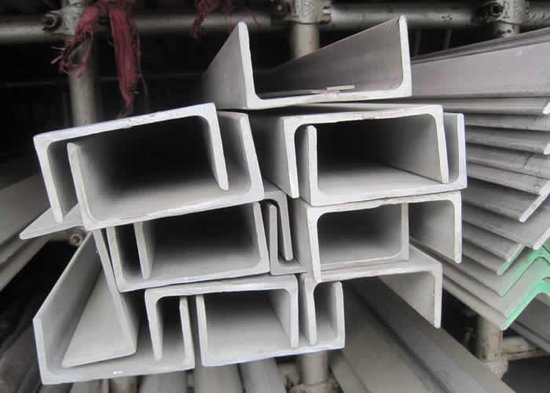

Stainless Steel Channel

- Loading Port:

- Shanghai Port or Others

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Channels

Stainless Steel Channel, is ideal for all applications where greater strength and superior corrosion resistance is required. Stainless Channel has a durable dull, mill finish that is widely used for all types of fabrication projects that are exposed to the elements - chemical, acidic, fresh water, and salt water environments

The standard length for most size channel is 12’-14’ random lengths, but lengths are available in some sizes up to 20’ and longer. Finishes on channel can vary and include cold drawn, centerless ground, smooth turned, rough turned, turned ground and polished, and HRAP.

· We will custom saw cut to length

· DEFARS or domestic material available in many sizes

· Polishing services are available

|

Product Name |

Stainless Steel Channel | |

|

Standard |

JIS, ASTM, GB, DIN, EN, AISI | |

|

Grade |

301,302,303,304,304L,305,309S,310S,316,316L,317,317L,321,347 631... | |

|

Diameter |

75x30x6mm many other sizes can be done | |

|

Length |

1m~6m |

|

|

Package Detail |

Export standard package, bundled or be required. The inner size of container is below: 20ft GP: 5.9m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM | |

|

Delivery Time |

Normally according to the order quantity or upon negotiation | |

|

Payment Terms |

L/C, T/T | |

|

Application |

Food stuff, gas, metallurgy, biology, electron, chemical, petroleum, boilers, nuclear, energy, construction field, ships building industry, war and electricity industry, boiler heat exchanger, machiner and hardware fields and medical equipment, fertilizer, etc.

| |

|

Contact |

Our products are very popular because of high-quality and reasonable prices. If you are interested in any of our products, please feel free to contact us for more information. | |

- Q: Galvanized steel plate, channel steel, angle steel how to take samples, how to submit?

- Sampling requirements: symmetry type steel (such as steel, T steel), in the distance where the interception endpoint 1/6 length long 500 mm, 20 mm wide rectangular healthy specimens, non symmetry type steel (such as steel, L steel), in the distance where the endpoint 1/3 length of 500 interception mm, 20 mm wide rectangular specimens. Direct interception of local plate in from the outer ends of the 12.5 mm long 500 mm, 20 mm wide rectangular specimens. Take one for tensile test and one for cold bending test.

- Q: Can stainless steel channels be welded or joined together?

- Yes, stainless steel channels can be welded or joined together. Stainless steel is a highly weldable material and can be easily joined using various welding techniques such as TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), or stick welding. These processes involve melting the stainless steel at the joint and adding a filler material to create a strong bond between the channels. Welding or joining stainless steel channels provides a secure and durable connection, making it suitable for various applications in construction, manufacturing, and engineering industries.

- Q: Can stainless steel channels be used in high-moisture or humid environments?

- Yes, stainless steel channels can be used in high-moisture or humid environments. Stainless steel is known for its excellent corrosion resistance properties, making it a suitable material for applications exposed to moisture, humidity, and other corrosive elements. The chromium content in stainless steel forms a protective layer on the surface, preventing oxidation and corrosion. This inherent resistance to corrosion allows stainless steel channels to withstand high-moisture or humid environments without deteriorating or rusting. Additionally, stainless steel is also resistant to staining and pitting, further enhancing its suitability for these environments. Therefore, stainless steel channels are a reliable choice for construction, industrial, and marine applications where exposure to moisture or humidity is likely.

- Q: Can stainless steel channels be used in food processing or sanitary applications?

- Indeed, it is possible to utilize stainless steel channels in food processing or sanitary applications. The utilization of stainless steel in these domains is highly favored due to its remarkable resistance to corrosion, enduring nature, and hygienic attributes. Stainless steel channels exhibit the capability to withstand repeated cleansing and sterilization procedures without any deterioration, rendering them appropriate for implementation in environments where cleanliness and hygiene hold paramount importance. Moreover, stainless steel does not interact with edibles or beverages, guaranteeing the preservation of product quality and taste. In summary, stainless steel channels represent a dependable and secure alternative for food processing and sanitary applications.

- Q: Can stainless steel channels be used in the construction of industrial shelving?

- Yes, stainless steel channels can be used in the construction of industrial shelving. Stainless steel is known for its durability, strength, and resistance to corrosion, making it suitable for heavy-duty applications such as industrial shelving. Additionally, stainless steel channels provide structural support and stability, making them a reliable choice for constructing shelves in industrial settings.

- Q: Can stainless steel channels be used for architectural cladding or façade systems?

- Yes, stainless steel channels can be used for architectural cladding or façade systems. Stainless steel is a durable and corrosion-resistant material that can withstand harsh weather conditions, making it suitable for exterior applications. The channels can be used to create sleek and modern designs, providing a visually appealing finish to buildings.

- Q: Are stainless steel channels suitable for use in agricultural or farming applications?

- Stainless steel channels are a perfect fit for agricultural or farming applications due to their durability and resistance to corrosion. This material is highly recommended for environments where it may encounter moisture or chemicals. In agricultural or farming settings, where exposure to water, fertilizers, and other corrosive substances is common, stainless steel channels can endure the harsh conditions and maintain their structural integrity for a long time. Furthermore, stainless steel's robustness and ability to withstand impact make it a suitable option for supporting heavy loads, thus making it a dependable choice for various agricultural equipment and structures. In summary, stainless steel channels offer exceptional durability and reliability in agricultural or farming applications, making them an ideal choice for such purposes.

- Q: What are stainless steel channels?

- Stainless steel channels are structural components made from stainless steel that have a C-shaped cross-section. They are commonly used in construction and engineering projects to provide support and reinforcement in various applications such as framing, bracing, and securing other materials.

- Q: How do you select the right size of stainless steel channel for a specific application?

- When selecting the right size of stainless steel channel for a specific application, there are a few factors to consider. Firstly, you need to determine the load capacity that the channel will need to support. This involves calculating the weight or force that will be applied to the channel, including any potential dynamic loads or vibrations. By understanding the load requirements, you can choose a channel size with the appropriate strength and structural integrity to handle the expected load. Secondly, it is important to take into account the dimensions and shape of the items or materials that will be placed or mounted on the channel. Consider the width, height, and depth of the items to ensure that the selected channel size can accommodate them securely and without any risk of instability. Additionally, the length of the stainless steel channel should also be considered. Measure the distance or span that the channel will need to cover and select a length that can adequately support the load across the entire span without any significant deflection or bending. It is also crucial to think about any specific requirements or regulations for the application. For example, if the stainless steel channel will be used in a corrosive environment or in contact with certain chemicals, you may need to choose a channel made from a specific grade of stainless steel that offers suitable corrosion resistance. Lastly, consulting with a structural engineer or an expert in stainless steel channels can provide valuable guidance and ensure that you select the right size for your specific application. They can help analyze the load requirements, evaluate the dimensions and shape of the items, and consider any other relevant factors to make an informed decision.

- Q: Are stainless steel channels magnetic?

- Negative, stainless steel channels do not possess magnetic properties. Although stainless steel does have a minor iron content, the inclusion of chromium and nickel, among other elements, in the alloy composition forms a safeguarding layer on the exterior, referred to as a passive layer. This passive layer renders stainless steel channels unmagnetic.

Send your message to us

Stainless Steel Channel

- Loading Port:

- Shanghai Port or Others

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords