Stainless Steel Sheets 201 low price tisco cold rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

stainless steel sheet

1.Thickness:0.1-150mm

2.Width:500-3000mm

3.Length:500-6000mm

4.BV ISO ROHS SGS

Stainless steel sheet

Item | Stainless steel sheet |

Description | Stainless steel sheet,stainless steel plate,cold rolled stainless steel sheet,hot rolled stainless steel sheet,stainless checkered sheet, stainless steel decorative sheet |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,BS,GB |

Material | 201,202,304,304L,309S,310S,316,316L,316Ti,317L,321,347H, 409,409L,410,420,430 |

Finish(Surface) | NO.1, NO.2D, NO.2B, BA,NO.3, NO.4,NO.240,NO.400,Hairline,NO.8, Brushed |

Exported Area | USA,UAE,Europe,Asia,Middle East,Africa,South America |

Thickness | Form 0.4mm to 100mm |

Width | 1000mm,1219mm(4feet),1250mm,1500mm,1524mm(5feet),1800mm,2200mm or we can also help the size as you require |

Length | 2000mm,2440mm(8feet),2500mm,3000mm,3048mm(10feet),5800mm, 6000mm or we can make the length as you require |

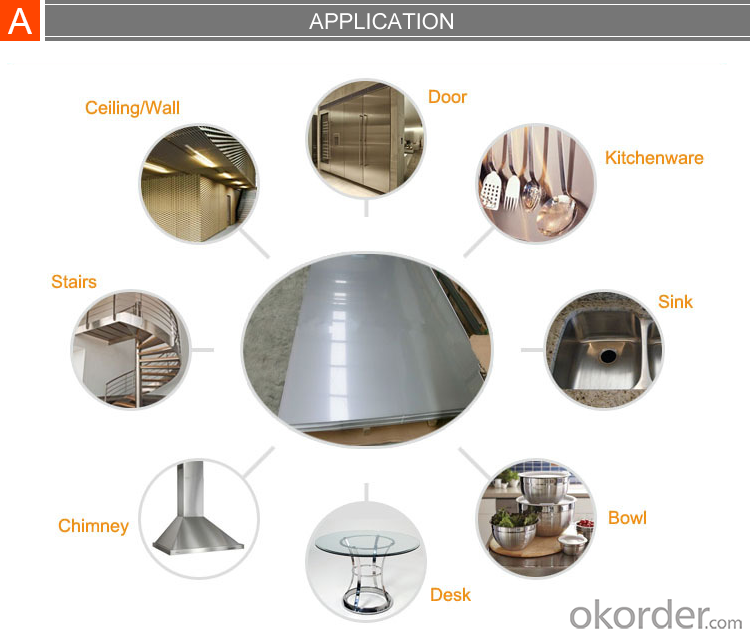

Application | Stainless steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heatexchanger, machinery and hardware fields. Stainless steel sheet can be made accordingto the customers requirements. Fast delivery. Quality assured.Welcome to order more. |

Package Detail | Standard seaworthy package(wooden boxes package,pvc package, and other package) |

Delivery Time | According to your size and quantity or as customers require |

Payment Term | T/T ,L/C |

Advantage | Good quality with reasonable price |

THE CHEMICAL COMPOSITION AND MECHANICAL PROPERTIES

| Grade | C (Max) | Mn (Max) | P (Max) | S (Max) | Si (Max) | Cr | Ni | Mo | Nitrogen (Max) | Cu/ Others |

| 201 | 0.15 | 5.50-7.50 | 0.06 | 0.03 | 1 | 16.00-18.00 | 3.50-5.50 | - | 0.25 | |

| 202 | 0.15 | 7.50-10.00 | 0.06 | 0.03 | 1 | 17.00-19.00 | 4.00-6.00 | - | 0.25 | |

| 301 | 0.15 | 2 | 0.045 | 0.03 | 1 | 16.00 - 18.00 | 6.00 - 8.00 | - | 0.1 | - |

| 304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.00 - 20.00 | 8.00- 10.50 | - | 0.1 | - |

| 304L | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.00 - 20.00 | 8.00- 12.00 | - | 0.1 | - |

| 310S | 0.08 | 2 | 0.045 | 0.03 | 1.5 | 24.00- 26.00 | 19.00-22.00 | - | - | - |

| 316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.00 - 18.00 | 10.00- 14.00 | 2.00 - 3.00 | 0.1 | - |

| 316L | 0.03 | 2 | 0.045 | 0.03 | 1 | 16.00 - 18.00 | 10.00- 14.00 | 2.00 - 3.00 | 0.1 | - |

| 316Ti | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.00 - 18.00 | 10.00- 14.00 | 2.00 - 3.00 | 0.1 | Ti5x C Min |

| 317 | 0.08 | 2 | 0.045 | 0.03 | 0.75 | 18.00 - 20.00 | 11.00 - 14.00 | 3.00 - 4.00 | 0.1 | - |

| 317L | 0.03 | 2 | 0.045 | 0.03 | 0.75 | 18.00 - 20.00 | 11.00 - 15.00 | 3.00 - 4.00 | 0.1 | - |

| 321 | 0.08 | 2 | 0.045 | 0.03 | 0.75 | 17.00 - 19.00 | 9.00 - 12.00 | - | 0.1 | Ti5xC Min |

| 347 | 0.08 | 2 | 0.045 | 0.03 | 0.75 | 17.00 - 19.00 | 9.00 - 13.00 | - |

- Q: Stainless steel plate net price, stainless steel plate net how much one meter?

- It has excellent corrosion resistance, acid, alkali and salt corrosion, which can meet the special requirements of oil well, not because of the erosion of the gap becomes larger; one welding multilayer structure, can make the filter hole stability, anti deformation ability.

- Q: What is 3042B stainless steel?

- 2B: the fog surface; after cold rolling, after heat treatment and acid washing, the finishing surface is made to be a fair light. As the surface is smooth, easy to re grinding, make the surface more bright, wide range of uses, such as tableware, building materials, etc.. Surface treatment with improved mechanical properties almost meets all uses.Stainless steel can be divided into Cr series (400 Series), Cr - Ni series (300 Series), Cr - Mn - Ni (200 Series), Heat-Resisting Chromium Alloy Steel (500 Series) and precipitation hardening system (600 series).

- Q: What type of stainless steel plate made by imported vibrating disk?

- Compared with similar products, the vibration disc produced by our factory is of high precision, low noise, long life and easy operation. It solves the problem of automatic sorting and feeding.

- Q: Are stainless steel sheets suitable for architectural column covers or cladding?

- Yes, stainless steel sheets are suitable for architectural column covers or cladding. Stainless steel is known for its durability, corrosion resistance, and aesthetic appeal, making it an excellent choice for exterior applications. It can withstand harsh weather conditions, maintain its appearance over time, and provide a sleek and modern look to architectural structures. Additionally, stainless steel sheets offer versatility in terms of finishes, patterns, and colors, allowing architects and designers to create unique and visually appealing column covers or cladding designs.

- Q: What are the different types of stainless steel sheet surface patterns available?

- There is a wide range of surface patterns available for stainless steel sheets, each possessing its own distinct qualities and aesthetic charm. Some of the most frequently encountered patterns are as follows: 1. Brushed: This texture is obtained by gently brushing the stainless steel surface with an abrasive material, resulting in a smooth and uniform appearance. It is commonly employed in scenarios where a sleek and contemporary appearance is desired. 2. Mirror: This pattern entails polishing the stainless steel surface to achieve a highly reflective finish, akin to that of a mirror. It is often utilized in decorative applications where a high degree of shine is sought after. 3. Satin: Also referred to as a brushed or hairline finish, this pattern is achieved by uniformly applying a fine abrasive substance to the stainless steel surface in a linear motion, resulting in a matte effect. It is commonly employed in architectural and kitchen applications. 4. Embossed: This pattern involves imprinting a design or texture onto the stainless steel surface using a patterned roller or press. It can produce a variety of decorative effects, such as raised or recessed patterns, and is frequently utilized in interior design and automotive applications. 5. Perforated: In this pattern, the stainless steel sheet is punctured with a series of small holes arranged in a regular pattern. This allows for improved ventilation and drainage capabilities and is commonly employed in architectural and industrial applications. 6. Etched: This pattern involves chemically treating the stainless steel surface to create a design or pattern. It can be used to produce intricate and detailed designs, making it popular in decorative and artistic applications. These examples merely scratch the surface of the diverse range of surface patterns available for stainless steel sheets. The choice of pattern often depends on the desired application, functionality, and visual appeal.

- Q: Can stainless steel sheets be used for elevator ceilings or floors?

- Yes, stainless steel sheets can be used for elevator ceilings or floors. Stainless steel is a durable and resistant material, making it suitable for areas that require frequent cleaning and maintenance, such as elevator interiors. Additionally, stainless steel offers an aesthetically pleasing and modern look, enhancing the overall appearance of elevator ceilings and floors.

- Q: What are the standard dimensions for stainless steel sheets?

- The standard dimensions for stainless steel sheets vary depending on the type and grade of stainless steel being used. However, there are some common sizes that are widely available in the market. For most stainless steel sheets, the standard width ranges from 36 inches to 48 inches, with a length varying between 72 inches to 120 inches. These dimensions are commonly used for stainless steel sheets used in various applications such as construction, automotive, and manufacturing. The thickness of stainless steel sheets can also vary, with common options ranging from 0.024 inches to 0.1875 inches. Thinner sheets are often used for decorative purposes or lightweight applications, while thicker sheets are utilized for heavy-duty applications that require higher strength and durability. It is important to note that these dimensions are general guidelines and can vary depending on the specific requirements of a project. Additionally, custom sizes can also be manufactured to meet the unique needs of a particular application. Overall, the standard dimensions for stainless steel sheets provide a range of options suitable for various industries and purposes, ensuring that there is flexibility in selecting the appropriate size for a specific project.

- Q: What are the different types of finishes available for stainless steel sheets?

- There are several different types of finishes available for stainless steel sheets, each offering its own unique appearance and level of protection. Some of the most common finishes include: 1. No. 1 Finish: This is a dull, rough, and non-reflective finish that is achieved by hot rolling the stainless steel sheet. It is commonly used for industrial applications where appearance is not a primary concern. 2. No. 2B Finish: This finish is a smooth, reflective surface achieved by cold rolling the stainless steel sheet and then annealing it in a controlled atmosphere. It is widely used in applications that require a visually appealing finish, such as kitchen appliances and decorative trim. 3. No. 4 Finish: Also known as brushed or satin finish, this is achieved by applying a series of abrasive grits to the surface of the stainless steel sheet. It creates a uniform, linear grain pattern that is commonly used for architectural and decorative purposes. 4. No. 8 Finish: This is a highly reflective finish that is achieved by polishing the stainless steel sheet to a mirror-like appearance. It is often used in applications where a sleek and sophisticated look is desired, such as in high-end architectural projects and automotive trim. 5. BA (Bright Annealed) Finish: This finish is achieved by annealing the stainless steel sheet in a controlled atmosphere and then pickling or blasting it to remove any oxide scale. It results in a smooth, bright surface that is commonly used in applications that require optimum corrosion resistance, such as medical equipment and pharmaceutical processing. 6. Hairline Finish: This finish is achieved by mechanically brushing the surface of the stainless steel sheet with fine abrasive belts. It creates a subtle, textured look that can be used for architectural and decorative purposes. 7. Embossed Finish: This finish involves imprinting a raised or recessed pattern onto the surface of the stainless steel sheet using a rolling mill or press. It adds texture and visual interest to the sheet and is often used in applications such as elevator interiors, wall cladding, and signage. These are just a few of the many finishes available for stainless steel sheets, each offering its own unique aesthetic and functional properties. The choice of finish depends on the specific application and desired appearance.

- Q: What is the machinability of stainless steel sheets?

- The machinability of stainless steel sheets can differ depending on the grade of stainless steel and its specific composition. Generally, stainless steel is known to have lower machinability in comparison to carbon steel or aluminum. This is primarily because of its higher strength, hardness, and work-hardening characteristics. During machining, stainless steel tends to work-harden, resulting in increased cutting forces and tool wear. It also has lower thermal conductivity, which can lead to higher temperatures during machining operations, further contributing to tool wear. Additionally, stainless steel has a unique chip formation behavior, often resulting in stringy and hard-to-break chips. However, advancements in cutting tool technology and machining techniques have made it possible to enhance the machinability of stainless steel. For example, using appropriate cutting tool geometries, coatings, and coolant/lubricant can help reduce cutting forces, minimize tool wear, and improve chip control. It is important to note that different grades of stainless steel can display varying levels of machinability. Austenitic stainless steels, such as 304 and 316, are generally more challenging to machine compared to ferritic or martensitic stainless steels. This is because of their higher nickel and chromium content, which contribute to their excellent corrosion resistance but also make them harder to machine. Overall, although machining stainless steel sheets may present some difficulties, with the right tools, techniques, and expertise, it is possible to achieve satisfactory machinability and produce high-quality components from stainless steel sheets.

- Q: What brand of stainless steel plate is good?

- It is an alloy steel which is not easily rusted, but it is not absolutely rusty. Stainless steel plate refers to the atmosphere, steam and water and other weak medium corrosion of steel plate, and acid resistant steel plate refers to acid, alkali, salt and other chemical corrosive medium corrosion of steel plate. Stainless steel plate has been published since the beginning of twentieth Century, and now has a history of more than 1 centuries.

Send your message to us

Stainless Steel Sheets 201 low price tisco cold rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords