Stainless Steel Sheet with Special Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50000 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Sheet with Special Surface Treatment

Description of Stainless Steel Sheet with Special Surface Treatment:

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widelyused in light industry,heavy industry,daily necessities and the decoration industry.my company long-termsupply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Main Features of SStainless Steel Sheet with Special Surface Treatment:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Maintance of Stainless Steel Sheet with Special Surface Treatment:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

Applications of Stainless Steel Sheet with Special Surface Treatment:

Stainless steel’s resistance to corrosion and staining, low maintenance and familiar lustre make it an ideal material for many applications. There are over 150 grades of stainless steel, of which fifteen are most commonly used. The alloy is milled into coils, sheets, plates, bars, wire, and tubing to be used in cookware, cutlery, household hardware, surgical instruments, major appliances, industrial equipment Storage tanks and tankers used to transport orange juice and other food are often made of stainless steel, because of its corrosion resistance and antibacterial properties. This also influences its use in commercial kitchens and food processing plants, as it can be steamcleaned and sterilized and does not need paint or other surface finishes..

Specifications of Stainless Steel Sheet with Special Surface Treatment:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Surface Finish Characteristics of Stainless Steel Sheet with Special Surface Treatment:

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

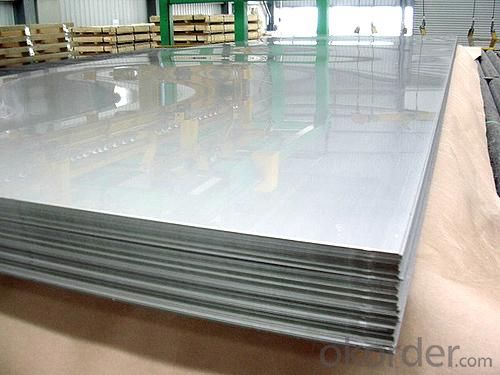

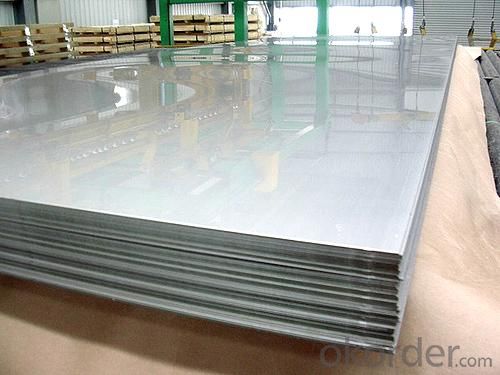

Images of Stainless Steel Sheet with Special Surface Treatment:

Sandard Seaworth Packing(wooden packing with water proof paper):

FAQ:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

Our company adheres to the tenet of "survival by quality, build brand by reputation, win market by prices and innovate to develop", has developed international markets and the products are well sold in many countries as Singapore, Indonesia, South Korea, Dubai, Pakistan, Sri Lanka, Vietnam, Iran, Malaysia, Mexico, Chile, Brazil, Holland, Italy, Belgium, Russia, Moldova, Paraguay, Uruguay, Germany, Spain, USA etc. More than 40 countries.; commonly we have more than 500tons stainless steel materials in stock; so w can arrange the soonest delivery too; also we hope we will have chance to cooperate with your esteemed company!

- Q: What are the common sizes of stainless steel sheets?

- Common sizes of stainless steel sheets vary depending on the industry and application. However, there are some standard sizes that are readily available in the market. For instance, stainless steel sheets commonly come in thicknesses ranging from 0.4mm to 3.0mm. The most common widths are 1000mm, 1219mm, and 1500mm, while the most common lengths are 2000mm, 2438mm, and 3000mm. These dimensions are often referred to as 4x8 (4 feet by 8 feet), as they are the standard size for stainless steel sheets used in various construction and fabrication projects. It's worth noting that stainless steel sheets can also be custom-cut to specific dimensions based on the requirements of a particular project. This allows for greater flexibility and ensures that the sheets fit perfectly for the intended application.

- Q: Are stainless steel sheets suitable for chemical transport containers?

- Yes, stainless steel sheets are suitable for chemical transport containers. Stainless steel is highly resistant to corrosion, making it an ideal material for withstanding the potentially corrosive nature of chemicals. It also offers excellent strength and durability, ensuring the safe transportation of chemicals without compromising their integrity. Additionally, stainless steel is easy to clean and maintain, which is crucial for preventing cross-contamination during transportation.

- Q: How do you straighten bent stainless steel sheets?

- To straighten bent stainless steel sheets, there are a few methods you can try depending on the severity of the bend. 1. Cold straightening: For slight bends, you can use a rubber mallet or a hammer to gently tap the bent area back into place. Start from the center of the bend and work your way towards the edges, applying gradual and even pressure. Be careful not to hit the stainless steel too hard, as it may cause further damage. 2. Heat straightening: If the bend is more severe, you can use heat to soften the stainless steel, making it easier to straighten. Start by heating the bent area using a blow torch or a heat gun. Once the stainless steel becomes red-hot, use pliers or a vice grip to carefully straighten the sheet. Keep in mind that this method should only be used for thicker stainless steel sheets, as thinner ones may warp or lose their shape if exposed to excessive heat. 3. Mechanical straightening: This method involves using specialized tools like a hydraulic press or a metal brake to apply controlled pressure and straighten the bent stainless steel sheet. This is recommended for large or heavy-duty sheets that cannot be easily straightened by hand. Ensure that you follow the manufacturer's instructions when using these tools to avoid any accidents. Remember to always wear appropriate safety gear, such as gloves and eye protection, when working with stainless steel sheets. If you are unsure or uncomfortable with straightening the sheets yourself, it is recommended to consult a professional metalworker or a fabrication shop for assistance.

- Q: Can stainless steel sheets be etched or engraved?

- Yes, stainless steel sheets can be etched or engraved using various techniques such as chemical etching, laser engraving, or mechanical engraving.

- Q: Are stainless steel sheets suitable for water tanks?

- Stainless steel sheets are indeed a great option for water tanks. Their resistance to corrosion makes them perfect for water storage. They won't react with the water or introduce any harmful substances into it. Additionally, stainless steel tanks are durable, require little maintenance, and have a long lifespan. They can handle high temperatures and extreme weather conditions without compromising their structural integrity. Moreover, stainless steel is non-porous, preventing the growth of bacteria and algae. These outstanding characteristics make stainless steel sheets a superb choice for water tanks in different settings, such as residential, commercial, and industrial environments.

- Q: Are stainless steel sheets heat-resistant?

- Indeed, stainless steel sheets possess impressive heat resistance. Renowned for their capacity to endure extreme temperatures without distorting or bending, stainless steel sheets prove to be an exceptional option for various heat-exposed purposes. The inclusion of chromium in stainless steel generates a protective coating on its surface, which effectively impedes oxidation and corrosion, even when subjected to elevated temperatures. As a result of this invaluable heat resistance attribute, stainless steel sheets are fitting for an extensive array of applications, encompassing industrial equipment, kitchen appliances, automotive components, and construction materials.

- Q: Can stainless steel sheets be used for chemical storage tanks?

- Yes, stainless steel sheets can be used for chemical storage tanks. Stainless steel is known for its corrosion resistance, making it an ideal choice for storing a wide range of chemicals. It is durable, easy to clean, and can withstand high temperatures and pressure, making it a reliable material for chemical storage applications.

- Q: What are the different types of surface treatments available for stainless steel sheets?

- There is a variety of surface treatments accessible for stainless steel sheets, each with its own purpose and distinct advantages. 1. The Mill Finish is the most basic type of surface treatment, achieved directly from the mill after the stainless steel sheet's manufacturing process. It presents a smooth, dull appearance and is commonly utilized for a clean, unembellished look. 2. The Brushed Finish, also known as satin finish, entails brushing the stainless steel surface with a fine abrasive substance to create fine parallel lines. This finish offers a decorative, textured appearance while concealing any surface imperfections or scratches. 3. The Mirror Finish creates a highly reflective surface resembling a mirror. It is attained by progressively polishing the stainless steel sheet with finer abrasives until a glossy, reflective finish is achieved. This finish is commonly used in decorative applications where a high level of shine is desired. 4. The Bead Blasted Finish involves blasting the stainless steel surface with tiny glass beads at high pressure. This creates a uniform, matte texture with a slightly rough feel. The bead blasted finish is often employed in architectural applications to achieve a modern, industrial appearance. 5. The Etched Finish involves applying an acid or chemical solution to the stainless steel surface to form intricate patterns or designs. This treatment allows for a high level of customization and is commonly used in architectural, signage, and decorative applications. 6. PVD Coating, or Physical Vapor Deposition, is a process where a thin film of a specific material is deposited onto the stainless steel surface using a vacuum chamber. This coating can provide various colors and finishes, such as gold, black, or bronze, while also enhancing the durability and corrosion resistance of the stainless steel sheet. These examples represent only a fraction of the diverse surface treatments available for stainless steel sheets. The choice of treatment depends on the desired aesthetic, functionality, and application requirements.

- Q: Can stainless steel sheets be used for oil and gas pipelines?

- Yes, stainless steel sheets can be used for oil and gas pipelines. Stainless steel is commonly used in the oil and gas industry due to its excellent corrosion resistance properties. It can withstand the harsh conditions of transportation and storage of oil and gas, including high-pressure, high-temperature, and corrosive environments. Stainless steel sheets are often utilized to fabricate pipeline components such as pipes, fittings, and flanges, as they offer durability, strength, and resistance to corrosion, which helps to prevent leaks and maintain the integrity of the pipeline.

- Q: How do you determine the best thickness of stainless steel sheet for a specific application?

- To determine the best thickness of stainless steel sheet for a specific application, several factors need to be considered. Firstly, the intended use of the stainless steel sheet is crucial. Different applications require different levels of strength, durability, and resistance to corrosion. For example, if the sheet will be used in a high-stress environment or exposed to harsh chemicals, a thicker gauge stainless steel sheet would be suitable to ensure sufficient strength and corrosion resistance. Secondly, the size and dimensions of the application should be taken into account. Larger structures or components may require thicker stainless steel sheets to maintain structural integrity and prevent deformation under load. Conversely, smaller or more delicate applications may benefit from thinner sheets to reduce weight and improve flexibility. Moreover, considering the expected lifespan and maintenance requirements is essential. Thicker stainless steel sheets generally offer greater longevity and can withstand more wear and tear. However, if the application requires frequent cleaning or maintenance, a thinner sheet may be more practical. Additionally, budgetary constraints should be taken into consideration. Thicker stainless steel sheets tend to be more expensive due to the increased material cost and manufacturing complexity. Balancing the desired performance with available resources is crucial to determine the most cost-effective thickness. Lastly, consulting industry standards, guidelines, and experts can provide valuable insights. Various industries have specific requirements for stainless steel sheet thickness based on their experiences and safety standards. Engaging with professionals can help to ensure the chosen thickness meets the necessary specifications and regulations. In summary, determining the best thickness of stainless steel sheet for a specific application involves considering the intended use, size, expected lifespan, maintenance requirements, budget, and seeking guidance from industry experts. By carefully evaluating these factors, one can make an informed decision to select the most suitable thickness for their particular needs.

Send your message to us

Stainless Steel Sheet with Special Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50000 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords