Stainless Steel Sheet 430 for Foodstuff, Biology, Petroleum, Nuclear Energy Medical Equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Stainless Steel Sheet 430 for Foodstuff, Biology, Petroleum, Nuclear Energy Medical Equipment

Packaging Details:Wooden pallets,water proof paper-20'GP or 40'GP for stainless steel sheet.

Delivery Detail:within 5-7 days after receiving the deposit

1. Specifications about stainless steel sheet

Commodity | Professional 430 201 202 304 304l 316 316l 321 310s 309s 904l stainless steel sheet |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

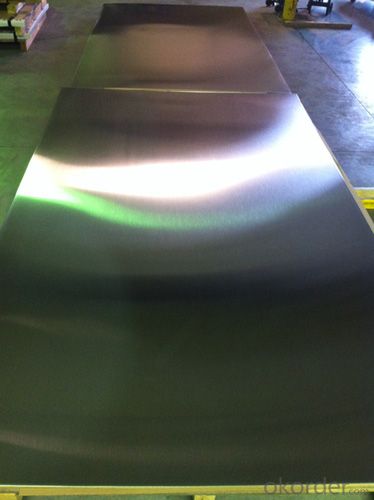

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 1 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

2.Production Flow about stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold; rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shiftoperation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealin and pickling by our experienced staff.

3.Surface--stainless steel sheet

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA/8K mirror | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

- Q: Can stainless steel sheets be used for power generation equipment?

- Yes, stainless steel sheets can be used for power generation equipment. Stainless steel is a versatile material that offers several beneficial properties for power generation applications. It has excellent corrosion resistance, which is crucial in environments where the equipment is exposed to water, steam, or other corrosive substances. Stainless steel also has high strength and durability, making it suitable for withstanding the high temperatures and pressures typically found in power generation systems. Additionally, stainless steel is a good conductor of electricity, making it suitable for electrical components and connections within the equipment. Therefore, stainless steel sheets are commonly used in the construction of power generation equipment such as turbines, boilers, heat exchangers, and exhaust systems.

- Q: Can stainless steel sheets be used for wire mesh?

- Certainly, wire mesh can be made from stainless steel sheets. Stainless steel, being a highly versatile material, finds extensive usage across numerous applications owing to its exceptional durability, resistance to corrosion, and strength. Once stainless steel sheets undergo processing to transform into wire mesh, they acquire a robust and dependable mesh structure. Industries like construction, agriculture, mining, and filtration often employ stainless steel wire mesh due to its remarkable ability to endure harsh environments, withstand rust and corrosion, and uphold its structural integrity throughout time.

- Q: Are stainless steel sheets suitable for laser cutting?

- Yes, stainless steel sheets are suitable for laser cutting. Laser cutting is an efficient and precise method for cutting stainless steel sheets, as lasers can easily penetrate the material and create clean, accurate cuts. Stainless steel sheets have high heat resistance, which makes them ideal for laser cutting as they can withstand the intense heat generated by the laser beam. Additionally, stainless steel sheets have excellent corrosion resistance, making them a popular choice for various industries. Laser cutting ensures minimal distortion and no contact with the material, resulting in a high-quality finished product.

- Q: Can stainless steel sheets be used for brewery piping?

- Certainly! Brewery piping can indeed utilize stainless steel sheets. Due to its corrosion resistance, durability, and hygienic qualities, stainless steel remains a favored material selection for brewery piping. It is capable of enduring the rigorous demands of the brewing process, including exposure to intense temperatures and harsh chemicals, thereby guaranteeing the integrity and cleanliness of the piping system. Moreover, stainless steel is effortlessly cleaned and maintained, rendering it exceptionally well-suited for breweries where cleanliness and sanitation are of utmost importance. In conclusion, stainless steel sheets are an unwavering and appropriate choice for brewery piping.

- Q: What are the different types of stainless steel sheet finishes for food processing applications?

- Various types of stainless steel sheet finishes are commonly used in food processing applications. 1. Achieved through hot rolling, the No. 1 Finish leaves the stainless steel sheet with a rough surface. Due to its lack of smoothness, it is not typically used in food processing applications as it can harbor bacteria. 2. The No. 2B Finish, on the other hand, is a smooth and reflective finish achieved through cold rolling and annealing of the stainless steel sheet. This finish is commonly used in food processing applications as it is easy to clean and maintain. 3. If a brushed appearance is desired, the No. 4 Finish is achieved by creating a uniform grain on the surface using abrasive materials. This finish is often used in food processing applications where a decorative or aesthetic finish is desired. 4. For the most reflective finish available, the No. 8 Mirror Finish is achieved by polishing the surface until it becomes highly reflective and mirror-like. This finish is often used in food processing applications that require a high level of cleanliness and hygiene. Aside from these finishes, there are also specialized finishes such as bead blasted, patterned, and embossed finishes that can be used in food processing applications to meet specific aesthetic or functional requirements. Ultimately, the choice of finish will depend on the specific needs of the food processing application, including factors such as hygiene, ease of cleaning, and aesthetic considerations.

- Q: What do stainless steel 304 industrial surfaces refer to?

- The industrial surface is the ordinary pickling surface, which is treated by the last pickling process. Is the kind of white surface that you see at ordinary times. The bright surface of life is the surface of which is further polished or annealed.

- Q: Are stainless steel sheets resistant to UV rays?

- Yes, stainless steel sheets are resistant to UV rays. Stainless steel is known for its durability and corrosion resistance, and this extends to its ability to withstand exposure to UV rays. The chromium content in stainless steel forms a protective oxide layer on the surface, which helps prevent the metal from oxidizing or corroding when exposed to sunlight. This oxide layer acts as a barrier that shields the stainless steel from UV rays, making it highly resistant to the damaging effects of prolonged sun exposure. Therefore, stainless steel sheets are an excellent choice for outdoor applications where UV resistance is a requirement, such as roofing, cladding, and architectural elements.

- Q: Comparison of three properties of aluminium plate, stainless steel plate and cold rolled plate?

- Stainless steel plate material is hard, not easy to shape, the color is monotonous, but the color is bright, not distortion;

- Q: Are stainless steel sheets resistant to acids?

- Acids don't stand a chance against stainless steel sheets. This remarkable material is famous for its ability to resist corrosion, and that includes acids too. You see, stainless steel contains chromium, which forms a protective layer called a passive film. This film acts like a barrier, preventing acids from reacting with the metal. It's like a superhero shield against a wide range of organic and inorganic acids. Of course, the level of resistance can vary depending on the type of stainless steel. Grades such as 304 and 316 are especially tough against acids, which makes them perfect for industries like chemical processing, food processing, and pharmaceuticals. But let's not forget, even though stainless steel sheets can handle acids pretty well, there are some aggressive acids and highly corrosive environments that can still break through their defenses. So, it's crucial to seek advice from experts and choose the right grade of stainless steel for acid-resistant applications.

- Q: Can stainless steel sheets be used for medical instrument trays?

- Indeed, medical instrument trays can make use of stainless steel sheets. The medical industry frequently utilizes stainless steel because of its remarkable resistance to corrosion, durability, and ease of cleaning. Medical instrument trays serve the purpose of storing and arranging diverse medical instruments during procedures. Stainless steel sheets are well-suited for this task due to their non-reactive nature and ability to withstand frequent sterilization processes, such as autoclaving. Furthermore, stainless steel possesses a sleek surface that can withstand scratches and dents, ensuring that the trays remain hygienic and easy to clean. All in all, stainless steel sheets prove to be a dependable and appropriate material option for medical instrument trays.

Send your message to us

Stainless Steel Sheet 430 for Foodstuff, Biology, Petroleum, Nuclear Energy Medical Equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords