stainless steel lotion pump hand press pump MZ-06

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 800000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product information

Item NO | MZ-D06 |

Specification | 28/400 |

Discharge rate | 1CC |

Material | SS, brushed SS |

Package | Carton |

Payment Terms | 30% deposit by T/T first ,70% balance before shipment |

MOQ | 10,000 pcs |

Supply Ability | 200,000/pcs/day |

Colour | Optional,any color can be made |

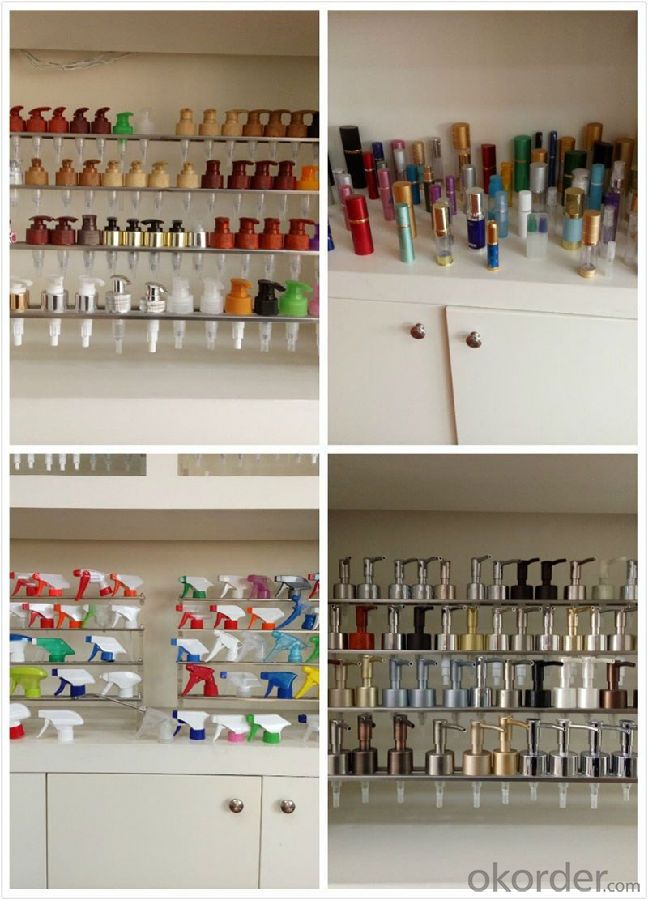

Product show

Package

About us

* More than 20 years of experience in the R&D and production of bathroom and kitchen accessories. We are proud to be one of the very few manufacturers that can provide unique products of bathroom pump, foam pump, trigger sprayer, perfume sprayer, liquid pump, liquid dispenser, perfume atomizer, cap, bottle, water dispenser and cosmetic jar .

* Innovative and fresh ideas are always welcomed by our design team. We strongly believe that the constant innovation is the key to the success and long-term development for our customers and us.

* A seasoned production team ensures us to provide our customers with high-quality products. Most of supervisors in our factory have more than 10 years of experience in the workshop management and plastic production.

* Equipped with the modernized production facilities, quality stability and reliability of products are effectively guaranteed.

Sample room

- Q: How to open Tupperware cup saves effort?

- When you close, you can put one side of the lid on the cup, press it with one thumb, and the other thumb down the top of the lid for a week, so it's easy to cover. These two methods seem some trouble, the actual use of very save energy (these methods should be in the purchase of the Tupperware cup to consultant tell you just bought a cup lid) will bear some of the use of a few days will be good

- Q: Bottle cap wrong direction, slippery silk, how to do, seek tips?

- Put it in the freezer, the metal cap shrinkage rate, cold will tighten, so it does not slip silk.

- Q: Do you need a lid to flush the toilet?

- Always put the lid on when you flush the toiletIf the flush toilet lid is opened, the toilet in the highest moment cyclone can be bacteria or microorganisms with 6 meters into the air, and suspended in the air for several hours, and then fell on the wall and a toothbrush, gargle, towel.

- Q: Will the bottle stopper automatically push out at a very low temperature?

- At very low temperatures (below ten degrees Celsius), the most concern is not whether the bottle top out, but whether the bottle burst problem, the main reason is the distribution of this area is not too cold, not because of cork.

- Q: Why does my printer always display the lid on, but my printer's lid is closed?

- Touch the lower edge of the lid and you'll see a bump. Corresponding to the lower part of the projection, there is a dent. When the cover or under the cover up, the pressure will be raised, or relax the transmission lever. Below the drive lever is a microswitch. The micro switch closed or opened, on behalf of the machine cover or open.

- Q: How do I open the wine bottle stopper?

- Note that the tip of the screw is inserted into the middle of the cork (if it is inserted on the side, it is easy to cause the cork to break or wood fragments fall into the wine), and then drill into the cork clockwise. If you use a butterfly shaped wine opener, when the screws go in, both sides of the handle will rise, and when the top, and then the two hands down at the same time, the cork will come out. If you are using a professional "friend of the waiter" screwdriver, be careful not to screw all drilling into the cork, but should stay a ring, because they will drill in the end will cork debris fall into the wine inside. After the cork is inserted, the metal fulcrum is placed on the bottle mouth, and a bottle shoulder is held in one hand, and the handle is lifted by a hand opener, and then the cork is lifted. If it's a long stopper, you can drill it back into the ring when it's halfway up.

- Q: After the ice box of the air conditioning fan is frozen, do you need to open the lid and put it in the water tank?

- First put the air conditioning fan and water tank, the ice in the refrigerator freezer to freeze for 1 to 2 hours, and then on the air conditioning fan in the water tank, the general ice can be used for 5-6 hours at a time, not cold in the cold in the fridge.

- Q: How are plastic caps made?

- The plastic pressing cover production process is:The mixed material into the pressure machine barrel suction machine, heating to a semi molten state in the plasticizing barrel after quantitative extrusion to the mold cavity, the upper and lower mold mold, plastic pressure and cooling, demoulding, after cutting ring, plus pad, complete the production of pressure plastic cover. Compare:The injection cover needs to be heated to a molten material flow, temperature at 250 degrees Celsius; plastic pressure only needs to be heated to 180 DEG C, the ratio of energy consumption high pressure injection molding cover;The moulding of low temperature, little shrinkage, cap size accurately;The injection of a fill all cavities, each time a bottle extrusion pressure plastic materials. Press extrusion pressure is very small, and injection molding needs high pressure;The injection molding of large volume, single cavity replacement trouble; plastic pressure for each cavity is relatively independent and can be replaced individually;The plastic bottle cover, pressing machine is a special machine, specifically for the design of bottle cap mold; injection molding machine not specifically designed to cap, so the pressure plastic cover can be made of horn, hanging cover rate is high, users love to use.

- Q: How do I open the wooden bottle cap?

- Open cap, with a piece of cloth on the wall, the bottle will hold in the hand, hit the wall gently with the bottom of the cloth, cork will slowly out of top, top to nearly half, put the bottle on the table, until the bubble disappears, slowly pull out the cork.

- Q: Will the lunch box be heated in the microwave and covered or not?

- Avoid the use of closed containers: heating liquid should use wide mouth containers, because in closed containers, the heating of food is not easy to emit, so that the pressure in the container is too high, easy to cause blasting accidents. Even in the boiling shelled food, but also advance the shell punctured with a needle or chopsticks, to avoid heating caused by the burst, splashing dirty furnace wall, or with people.

Send your message to us

stainless steel lotion pump hand press pump MZ-06

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 800000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords