Stainless Steel Cold Rolled Stainless Plates NO.2B Finish

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications for Stainless Steel Coils/Sheets:

Type | 200 series,300 series,400 series |

Thickness | 1.8-8.0mm |

Widthness | 1000/1219/1500mm |

Technique | Hot Rolled/Cold Rolled |

Coil Weight | About 20 Tons |

Finish | NO.1/NO.2B |

Place of Origin | Made in China |

MOQ | 18 ton |

Color | Black,Mirror Finished |

Standard | ASTM, JIS, GB, BS, DIN etc |

Exporting countries | Peru,India,Pakistan,Singpore,Vietnam,South Korea,Malaysia etc. |

After-sales service | Factory Inspection |

Certifications | ISO,SGS |

Packaging | Standard export packing or following customer's demand |

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

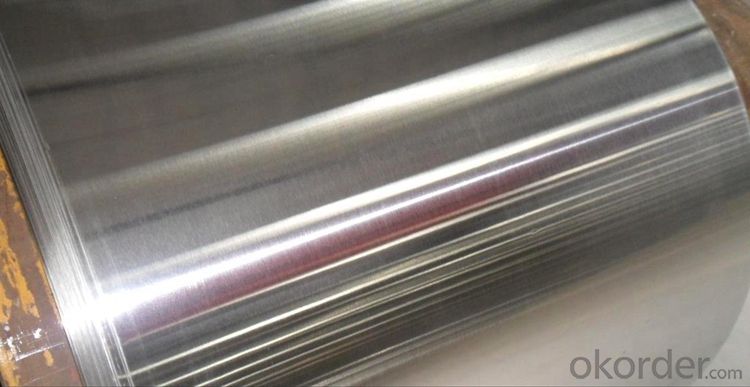

Detail picture for Stainless Steel Coils/Sheets

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

Export Markets for Stainless Steel Coils/Sheets:

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

Our Service

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: Are stainless steel sheets suitable for chemical processing equipment?

- Stainless steel sheets prove to be an ideal option for chemical processing equipment. Their exceptional corrosion resistance is well-known, rendering them impervious to chemical substances and surroundings. Moreover, stainless steel exhibits durability, strength, and effortless cleanability, making it the preferred material for chemical processing equipment that necessitates frequent exposure to diverse chemicals and rigorous cleaning protocols. Additionally, stainless steel boasts a high melting point, rendering it suitable for handling the elevated temperatures typically encountered in chemical processes. In summary, stainless steel sheets are an outstanding selection for chemical processing equipment due to their corrosion resistance, durability, strength, and ease of upkeep.

- Q: What is the cost of stainless steel sheets?

- The cost of stainless steel sheets can vary depending on various factors such as size, thickness, grade, and quantity. It is best to contact a supplier or check online marketplaces to get a specific and up-to-date price for stainless steel sheets.

- Q: What are the cost considerations when purchasing stainless steel sheets?

- When purchasing stainless steel sheets, there are several cost considerations to keep in mind. Firstly, the grade of stainless steel will greatly impact the cost. Stainless steel is available in various grades, with each grade possessing different properties and levels of corrosion resistance. Higher grades such as 316 or 304 tend to be more expensive due to their superior corrosion resistance and durability. The size and thickness of the stainless steel sheets also affect the cost. Thicker sheets generally cost more than thinner ones, and larger sheets will be priced higher than smaller ones. It is important to accurately determine the required size and thickness to avoid unnecessary expenses. Surface finish is another factor that can influence the cost. Stainless steel sheets come in a range of finishes, such as brushed, mirror, or matte. Finishes that require additional processing or polishing will usually add to the overall cost. Additionally, the quantity of sheets needed can impact pricing. Bulk purchases often offer discounts or lower per-unit costs compared to buying small quantities. Transportation and delivery costs should also be considered. Stainless steel sheets are heavy and can be expensive to transport, especially if shipping long distances. It is important to factor in these costs to ensure the overall purchase remains within budget. Lastly, it is crucial to consider the reputation and reliability of the supplier. While lower-priced options may be tempting, it is important to ensure that the supplier provides high-quality stainless steel sheets that meet the required specifications. Purchasing from a reputable supplier may come at a slightly higher cost, but it guarantees the quality and reliability of the product. Overall, when purchasing stainless steel sheets, it is vital to consider the grade, size, thickness, surface finish, quantity, transportation costs, and the reputation of the supplier. By carefully considering these factors, one can make an informed decision that balances cost-effectiveness with the desired quality and specifications.

- Q: Are stainless steel sheets resistant to chemicals and acids?

- Yes, stainless steel sheets are generally resistant to chemicals and acids due to the protective layer of chromium oxide that forms on their surface, which prevents corrosion and damage.

- Q: How do you prevent stress corrosion cracking in stainless steel sheets?

- To prevent stress corrosion cracking in stainless steel sheets, several measures can be taken. First and foremost, selecting the appropriate grade of stainless steel that is resistant to stress corrosion is crucial. Additionally, avoiding exposure to corrosive environments, such as chloride-containing solutions or high temperatures, is important. It is also recommended to minimize or eliminate tensile stresses through proper handling, fabrication, and installation techniques. Lastly, implementing regular inspection and maintenance practices can help detect any signs of stress corrosion cracking early on and take necessary preventive measures.

- Q: Can stainless steel sheets be used for walkways and platforms?

- Yes, stainless steel sheets can be used for walkways and platforms. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for outdoor applications like walkways and platforms. It can withstand heavy loads, harsh weather conditions, and frequent foot traffic without deteriorating or rusting. Additionally, stainless steel has a sleek and modern appearance that can enhance the aesthetic appeal of walkways and platforms. It is also easy to clean and maintain, ensuring longevity and safety for users.

- Q: Are stainless steel sheets resistant to staining from food?

- Stainless steel sheets possess a remarkable resistance to staining caused by food. Renowned for its exceptional corrosion resistance and non-reactivity with various substances, including food, stainless steel stands as a favored choice for kitchen appliances and cookware. Its capacity to endure prolonged exposure to food without staining or undergoing chemical reactions makes it highly sought-after. Moreover, stainless steel sheets are effortless to clean, making them the perfect fit for food preparation areas where cleanliness is of utmost importance. Furthermore, the sleek and impermeable surface of stainless steel sheets prevents the absorption of food particles and liquids, thus minimizing the risk of staining. In summary, stainless steel sheets offer a long-lasting and stain-resistant alternative for applications related to food.

- Q: What are the properties of stainless steel sheets?

- Stainless steel sheets possess multiple properties that make them extremely desirable in various industries and applications. To begin with, their excellent corrosion resistance is a result of the presence of chromium in the alloy, which forms a protective oxide layer on the surface, preventing rust and staining. Moreover, stainless steel sheets are renowned for their strength and durability. They can withstand heavy loads and resist deformation due to their high tensile strength. This makes them suitable for applications requiring structural integrity and longevity, such as in construction, automotive, and aerospace sectors. Another significant property of stainless steel sheets is their resistance to heat and fire. They can endure high temperatures without losing their structural integrity or strength. As a result, they are ideal for applications involving extreme heat, like commercial kitchens and industrial furnaces. Additionally, stainless steel sheets are hygienic and easy to clean, making them suitable for use in the food and medical industries. Their non-porous surface prevents the growth of bacteria, making them a reliable choice for food processing equipment, surgical instruments, and medical devices. They also possess an attractive appearance, with a smooth, reflective surface that is easy to maintain. This makes them aesthetically pleasing and suitable for architectural and decorative applications, such as building facades, interior design, and furniture manufacturing. Lastly, stainless steel sheets are highly versatile and can be easily formed, welded, and fabricated into various shapes and sizes. This flexibility allows for customization and adaptation to specific project requirements, offering designers and engineers a wide range of possibilities. In summary, stainless steel sheets offer corrosion resistance, high strength and durability, heat and fire resistance, hygiene, ease of cleaning, an attractive appearance, and versatility. These properties have made them a popular choice in numerous industries, ensuring their widespread use in various applications.

- Q: Can stainless steel sheets be used for electrical or electronic applications?

- Indeed, stainless steel sheets are applicable for both electrical and electronic purposes. Due to its remarkable electrical conductivity and resistance to corrosion, stainless steel proves to be an optimal material for a diverse range of electrical components. Electrical enclosures, switchgear, control panels, and various other electrical equipment commonly incorporate stainless steel. Moreover, its versatility allows stainless steel sheets to be fabricated into different forms and dimensions, rendering them suitable for a variety of electronic applications like printed circuit boards (PCBs), connectors, and terminals. Furthermore, the durability and ability to withstand high temperatures make stainless steel the preferred choice for electrical and electronic purposes in harsh environments.

- Q: Stainless steel thermos cup 304 and 201 material what is the difference?

- 304 stainless steel prices higher: in terms of price, 304 is far higher than the price of 201. Because 304 quality is better than 201 stainless steel, and 304 for imported stainless steel plate, 201 for domestic stainless steel plate, so 304 of the price is naturally higher.

Send your message to us

Stainless Steel Cold Rolled Stainless Plates NO.2B Finish

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords