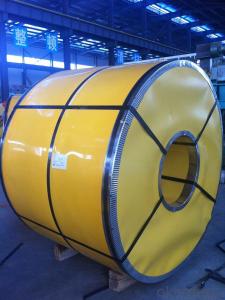

Stainless Steel Coil/Sheet 304 Cold Rolled 2B/BA

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Chemical composition: | |||||||

C | Si | Mn | Cr | Ni | S | P | |

≤0.07 | ≤1.0 | ≤2.0 | 18.0~20.0 | 8.0~11.0 | ≤0.03 | ≤0.035 | |

mechanical properties: | |||||||

Tensile strength σb (MPa) | Conditions yield strength 0.2 sigma (MPa) | Elongation δ5 (%) | Section shrinkage (%) | Hardness | |||

520 | 205 | 40 | 60 | ≤1 | |||

Packaging Detail: standard export packing or as customer's requirements

Delivery Detail: 7-15 days after the order

- Q: What are the applications of stainless steel strips?

- Stainless steel strips have a wide range of applications across various industries due to their exceptional properties. Some common applications of stainless steel strips include: 1. Construction and architecture: Stainless steel strips are commonly used in construction projects for structural components, roofing, cladding, and facades. Their durability, corrosion resistance, and aesthetic appeal make them an ideal choice for architectural applications. 2. Automotive industry: Stainless steel strips are used in the automotive industry for various purposes, such as manufacturing exhaust systems, trim components, and decorative parts. The high strength, heat resistance, and corrosion resistance of stainless steel strips make them suitable for these applications. 3. Kitchen appliances: Stainless steel strips are extensively used for manufacturing kitchen appliances like refrigerators, ovens, dishwashers, and sinks. Their hygienic properties, resistance to stains and corrosion, and easy cleaning make stainless steel strips a popular choice in the kitchen. 4. Medical equipment: Stainless steel strips find applications in the medical field for manufacturing surgical instruments, implants, and medical devices. Their biocompatibility, resistance to sterilization processes, and corrosion resistance make them suitable for use in healthcare settings. 5. Petrochemical industry: Stainless steel strips are utilized in the petrochemical industry for manufacturing equipment such as storage tanks, pipelines, and valves. The corrosion resistance of stainless steel strips is crucial in ensuring the safety and reliability of these critical components. 6. Electronics and electrical industry: Stainless steel strips are used in electronic devices, electrical contacts, connectors, and circuits due to their electrical conductivity and corrosion resistance. They provide excellent shielding against electromagnetic interference and offer long-term reliability. 7. Food processing industry: Stainless steel strips are widely used in the food processing industry for manufacturing equipment like conveyors, mixers, tanks, and processing machinery. Their corrosion resistance, easy cleaning, and hygienic properties make them suitable for handling food products. 8. Aerospace industry: Stainless steel strips are used in the aerospace industry for manufacturing aircraft components like turbine blades, exhaust systems, and structural parts. Their high strength-to-weight ratio, resistance to extreme temperatures, and corrosion resistance are critical in aerospace applications. These are just a few examples of the numerous applications of stainless steel strips. The versatility, durability, and corrosion resistance of stainless steel strips make them a preferred choice in various industries where strength, reliability, and aesthetics are essential.

- Q: How do stainless steel strips handle exposure to chlorine?

- Stainless steel strips are highly resistant to corrosion and can handle exposure to chlorine quite effectively. Chlorine is a highly reactive element and can cause corrosion in many metals, but stainless steel contains a high amount of chromium which forms a protective oxide layer on its surface. This oxide layer acts as a barrier, preventing chlorine from reaching the underlying metal and thus protecting the stainless steel strip from corrosion. Additionally, stainless steel also contains other alloying elements like nickel and molybdenum, which further enhance its resistance to corrosion in chlorine-rich environments. Overall, stainless steel strips are an excellent choice for applications that involve exposure to chlorine, as they can maintain their strength and integrity even in harsh conditions.

- Q: What is the lifespan of stainless steel strips?

- The lifespan of stainless steel strips can differ based on several factors, including the grade of stainless steel, the environment they are used in, the maintenance practices followed, and the specific application they are being used for. Stainless steel is widely recognized for its resistance to corrosion and durability, which contribute to its extended lifespan compared to other materials. In most scenarios, stainless steel strips can endure for many decades, if not longer. The remarkable corrosion resistance of stainless steel helps prevent rust and deterioration, significantly extending its lifespan. Additionally, stainless steel can withstand extreme temperatures, chemicals, and physical wear and tear, making it suitable for a wide range of applications. Nevertheless, it is important to consider that external factors can influence the lifespan of stainless steel strips. For example, if the strips are exposed to highly corrosive environments, like saltwater or acidic conditions, their lifespan may be shortened. In such instances, regular maintenance and proper cleaning can help extend their lifespan. Moreover, the grade of stainless steel used in the strips can also impact their lifespan. Certain grades, such as 316 or 2205, are specifically engineered to withstand harsh environments and offer enhanced corrosion resistance compared to lower grades. To maximize the lifespan of stainless steel strips, it is crucial to adhere to proper installation and maintenance practices. This may involve regular cleaning, applying protective coatings, and avoiding contact with incompatible materials. In conclusion, stainless steel strips possess a lengthy lifespan due to their inherent corrosion resistance and durability. However, the actual lifespan can vary based on factors like grade, environment, maintenance, and application. By selecting the appropriate grade, following proper maintenance practices, and considering the specific requirements of the application, stainless steel strips can deliver exceptional longevity and performance.

- Q: How do stainless steel strips perform in low temperature environments?

- Stainless steel strips perform exceptionally well in low temperature environments due to their inherent properties such as high strength, corrosion resistance, and toughness. They are capable of maintaining their structural integrity, durability, and resistance to brittleness even in extremely cold temperatures.

- Q: Can stainless steel strips be used in automotive body panels?

- Yes, stainless steel strips can be used in automotive body panels. Stainless steel is a versatile and durable material that offers excellent corrosion resistance, high strength, and a sleek appearance. These properties make it suitable for use in automotive applications, including body panels. Stainless steel strips can be shaped, welded, and formed into different panel designs, allowing for flexibility in design and customization. Additionally, stainless steel's resistance to rust and oxidation makes it ideal for withstanding harsh outdoor conditions and road salt exposure, which are common in automotive environments. Overall, stainless steel strips provide a reliable and long-lasting solution for automotive body panels.

- Q: Can stainless steel strips be used for heat exchanger plates?

- Yes, stainless steel strips can be used for heat exchanger plates. Stainless steel is a popular choice for heat exchangers due to its excellent corrosion resistance, high strength, and thermal conductivity. The strips can be formed into the required shape and size, making them suitable for use as heat exchanger plates.

- Q: What are the common applications for stainless steel strips?

- Stainless steel strips possess unique properties and versatility, making them widely utilized in various industries. They find applications in: 1. The automotive industry, where they are employed to produce exhaust systems, trim, and decorative elements. Their corrosion resistance and high strength enable them to withstand harsh conditions and ensure durability. 2. The construction industry, where stainless steel strips are frequently used for architectural purposes like cladding, roofing, and façades. Their aesthetic appeal, resistance to corrosion, and low maintenance requirements make them a popular choice for modern buildings. 3. Kitchen appliances, where stainless steel strips are commonly utilized in the production of refrigerators, dishwashers, and ovens. They offer a sleek and hygienic surface, resistance to stains, and ease of cleaning, making them favored materials in the food industry. 4. The medical field, where stainless steel strips are extensively employed for manufacturing surgical instruments, implants, and diagnostic equipment. Their biocompatibility, resistance to corrosion, and sterilization capabilities make them indispensable in healthcare settings. 5. The electronics industry, particularly for shielding purposes in electronic devices. Stainless steel strips provide electromagnetic interference (EMI) protection and are used in electronic enclosures and connectors. 6. The aerospace industry, where stainless steel strips are utilized for various applications, including aircraft components, engine parts, and structural elements. They offer high strength, heat resistance, and corrosion resistance, ensuring safety and reliability in extreme conditions. 7. The energy sector, where stainless steel strips are used in power plants, oil and gas pipelines, and renewable energy systems. They exhibit resistance to high temperatures, corrosion, and mechanical stress, making them suitable for these demanding environments. In summary, stainless steel strips are extensively employed in a wide range of applications due to their exceptional properties, including corrosion resistance, strength, durability, and aesthetic appeal.

- Q: What are the common uses of stainless steel strips in the aerospace industry?

- Due to their exceptional properties and characteristics, stainless steel strips find numerous applications in the aerospace industry. Fabricating aircraft components is one of their primary uses. These strips are crucial in producing structural parts like wing spars, fuselage frames, and landing gear components. The outstanding strength and corrosion resistance of stainless steel make it the perfect material for these critical components. It guarantees the aircraft's structural integrity and longevity. Aerospace manufacturers often prefer stainless steel strips over other materials due to their ability to endure extreme temperatures and pressures encountered during flight. Another significant application of stainless steel strips in the aerospace industry involves exhaust systems. These strips are essential in constructing exhaust pipes, mufflers, and heat shields. Thanks to stainless steel's heat resistance properties, it can withstand the high temperatures generated by aircraft engines while maintaining its structural integrity. Furthermore, stainless steel strips are employed in fabricating fuel tanks and hydraulic systems for aircraft. The corrosion resistance of stainless steel guarantees the protection and longevity of these vital components, preventing leaks and failures. Moreover, stainless steel strips are utilized in aerospace fastener manufacturing. They are instrumental in creating a range of screws, bolts, and rivets that hold aircraft components together. The high tensile strength and durability of stainless steel make it the ideal material for these fasteners, ensuring the aircraft's structural stability and safety. In conclusion, stainless steel strips play a crucial role in the aerospace industry due to their outstanding properties. They are widely used in fabricating structural components, exhaust systems, fuel tanks, hydraulic systems, and fasteners. The high strength, corrosion resistance, and heat resistance of stainless steel make it an indispensable material for guaranteeing the safety, reliability, and performance of aircraft.

- Q: Are stainless steel strips suitable for architectural roof cladding?

- Yes, stainless steel strips are suitable for architectural roof cladding. Stainless steel is a durable and corrosion-resistant material, making it ideal for outdoor applications such as roof cladding. It can withstand harsh weather conditions, including rain, snow, and UV radiation, without deteriorating or losing its aesthetic appeal. Additionally, stainless steel is available in various finishes and colors, allowing architects to choose from a wide range of options to achieve the desired design aesthetic. Its versatility, strength, and low maintenance requirements make stainless steel strips an excellent choice for architectural roof cladding.

- Q: Are stainless steel strips suitable for architectural mesh applications?

- Yes, stainless steel strips are suitable for architectural mesh applications. Stainless steel is a durable and corrosion-resistant material, making it perfect for outdoor or high-traffic areas. It offers excellent strength and stability while also allowing for flexibility in design and installation. Additionally, stainless steel mesh can provide security and privacy while still allowing for airflow and visibility. With its aesthetic appeal and functionality, stainless steel strips are an ideal choice for architectural mesh applications.

Send your message to us

Stainless Steel Coil/Sheet 304 Cold Rolled 2B/BA

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords