Stainless Steel Coil Cold Rolled 201 Half Cu 0.8 Prime Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Stainless Steel Coil Cold Rolled 201 Descriptions

Stainless Steel 201 is a new kind of Austenite stainless steel by used Mn, N replace Ni. The steel has good corrosion resistance and hot / cold processing performance, instead of 304 stainless steel products for used in the not high of corrosive environment, such as indoor, inland city outdoor etc.

2. Main Features of the Stainless Steel Coil Cold Rolled 201

Product name: Stainless Steel Coil Cold Rolled 201

Thickness: 0.2mm to 1.5mm

Technical: Cold Rolled

Width: 10mm to 1240mm

Type: 200 Series

Length: As customer's requested

Standard: JIS, SUS, AISI, ASTM

Grade: 201-J1, 201-J4, AISI201, AISI202…

Finish: BA, 2B, 8K, NO.3, NO.4, HL…

MOQ: 25 Metric Tons

Hardness: Low Hard(190 HV Max); Half Hard(240-280HV); Full Hard(42-60 HRC)

Ship Term: FOB any port, China or CFR Destination port

Delivery Time: 15 to 20 day after the receive the deposit or 100%LC

Payment Terms: TT 30% for deposit, Balance against the copy of B/L, or 100%LC

Packaging: By wooden pallet, wooden case or according to customer's request

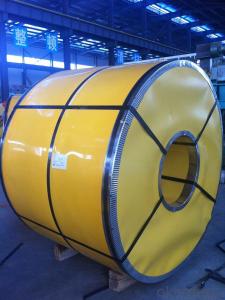

3. Stainless Steel Coil Cold Rolled 201 Images

4. Stainless Steel Coil Cold Rolled 201 Specifications

Mechanical Property Contrast | YS (Mpa) | TS (Mpa) | EL(%) | HV | REMARK |

Stainless Steel 201 | 426 | 880 | 52 | 224 | 1.0t |

Stainless Steel 304 | 285 | 710 | 58 | 165 | 1.0t |

Stainless Steel 200 Series Chemicals Contrast (wt. %) | ||||||||

Chemicals | C | Si | Mn | Cr | Ni | N | Other | |

205 | 0.12-0.25 | ≤0.75 | 14.0-15.0 | 16.5-18.0 | 1.0-1.75 | 0.32-0.4 | ||

JIS, | 201 | ≤0.15 | ≤1.0 | 5.5-7.5 | 16.0-18.0 | 3.5-5.5 | ≤0.25 | - |

201L | ≤0.03 | ≤0.75 | 5.5-7.5 | 16.0-18.0 | 3.5-5.5 | ≤0.25 | - | |

202 | ≤0.15 | ≤1.0 | 7.5-10.0 | 17.0-19.0 | 4.0-6.0 | ≤0.25 | - | |

201LN | ≤0.03 | ≤0.75 | 6.4-7.5 | 16.0-17.5 | 4.0-5.5 | 0.1-0.25 | Cu≤1.0 | |

India | 201-J1 | ≤0.08 | ≤0.75 | 7.0-8.0 | 15.0-17.0 | 4.0-5.0 | ≤0.1 | Cu≤1.5 |

201-J3 | ≤0.08 | ≤0.75 | 9.0-10.5 | 14.0-16.0 | 2.0-3.0 | ≤0.15 | Cu≤2.0 | |

201-J4 | ≤0.10 | ≤0.75 | 8.5-10.0 | 15.0-16.0 | ≤1.2 | ≤0.2 | Cu≤2.0 | |

America | 204 | ≤0.03 | ≤1.0 | 7.0-9.0 | 15.0-17.0 | 1.5-3.0 | 0.15-0.3 | (Cu) |

H400 | ≤0.10 | ≤1.0 | 6.0-9.0 | 17.0-19.5 | ≤3.5 | ≤0.3 | - | |

Japan | YUS130S | 0.09 | 0.5 | 11.0 | 18.0 | 6.5 | 0.35 | - |

NTK S-4 | 0.17 | 0.43 | 14.7 | 17.7 | 1.3 | 0.35 | - | |

NM15M | 0.08 | 0.8 | 14.5 | 17.0 | 4.3 | 0.33 | - | |

Europe America | 219 | ≤0.04 | ≤0.75 | 8.0-10.0 | 19.0-21.5 | 5.5-7.5 | 0.15-0.4 | - |

Cromanite | ≤0.08 | ≤1.0 | 9.5-11.0 | 18.0-20.0 | ≤1.0 | 0.4-0.6 | - | |

201 Surface | Characteristic and Application of Stainless Steel Coil Cold Rolled 201 |

2B | The surface brightness and flatness of 2B is better than 2D then through a special surface treatment to improve its mechanical properties,2B could nearly Satisfy comprehensive uses |

No.4 | Polished with abrasive belt of grit#150#180, have better brightness with discontinuous coarse stria, but thinner than NO.3, are used as bathtub buildings inner and electrical appliances kitchen utensils and food processing. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness like mirror kitchen apparatus, etc. |

8K | The product have excellent brightness and prefer bright can be the mirror. |

5. FAQ of Stainless Steel Coil Cold Rolled 201

Q: Can you provide mill test certificate?

A: Yes! Mill test certificate for both hot rolled raw material coils and cold rolled coils are available.

Q: How to get a sample?

A: Free samples are available for your checking and testing. And to get free samples, please send us your detailed receiving address (including post code) and your DHL/FEDEX/UPS account for collecting samples, courier cost will be paid in your side.

Q: How about your company?

A world class manufacturer & supplier of castings forging in stainless steel, is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 90000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service are available, all according to customer’s requirements.

Q: How to guarantee the quality of the products?

A: We have established the international advanced quality management system,every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

Q: How is the packaging and delivery?

A: Standard export packing (Coil: waterproof paper + protective steel ring; Circle: wooden box), or as your requirement and the delivery term is based on the project.

- Q: How do stainless steel strips resist stress corrosion cracking?

- Stainless steel strips resist stress corrosion cracking due to their high levels of chromium, which forms a protective oxide layer on the surface. This oxide layer acts as a barrier, preventing the corrosive environment from reaching the underlying metal and causing cracking.

- Q: Are stainless steel strips suitable for heat exchangers?

- Yes, stainless steel strips are suitable for heat exchangers. Stainless steel has excellent corrosion resistance, high thermal conductivity, and good mechanical properties, making it a suitable material for heat exchanger applications. It can withstand high temperatures, resist scaling and oxidation, and is easy to clean, making it an ideal choice for efficient heat transfer in various industries.

- Q: Are stainless steel strips resistant to chloride stress corrosion cracking?

- Generally, stainless steel strips exhibit resistance to chloride stress corrosion cracking. The corrosion resistance properties of stainless steel are widely recognized, encompassing resistance to chloride stress corrosion cracking. This is attributed to the abundance of chromium in stainless steel, which generates a protective oxide layer on the material's surface, prohibiting the infiltration of chloride ions and subsequent corrosion. Nevertheless, it is vital to acknowledge that the resistance to chloride stress corrosion cracking may fluctuate depending on the specific stainless steel type and grade, as well as the environmental conditions in which the material is exposed. Thus, it is always advisable to refer to the manufacturer's specifications and guidelines to ensure the appropriate stainless steel grade is chosen for the intended application.

- Q: Are stainless steel strips suitable for outdoor applications?

- Indeed, stainless steel strips prove to be well-suited for outdoor applications. Renowned for its exceptional resistance to corrosion, stainless steel showcases remarkable durability when exposed to outdoor elements. With its resistance to rust, oxidation, and weathering, it emerges as the ideal choice for applications that will encounter moisture, rain, or extreme temperatures. Furthermore, stainless steel's resistance to UV radiation renders it appropriate for outdoor applications exposed to sunlight. Its robustness and durability also render it fitting for outdoor applications necessitating resistance against wear and tear. All in all, stainless steel strips serve as a dependable and enduring alternative for a multitude of outdoor applications.

- Q: Can stainless steel strips be used for heat exchanger plates?

- Yes, stainless steel strips can be used for heat exchanger plates. Stainless steel is a popular choice for heat exchangers due to its excellent corrosion resistance, high strength, and thermal conductivity. The strips can be formed into the required shape and size, making them suitable for use as heat exchanger plates.

- Q: Can stainless steel strips be used in medical implant manufacturing?

- Yes, stainless steel strips can be used in medical implant manufacturing. Stainless steel is a commonly used material in the medical field due to its excellent corrosion resistance, high strength, and biocompatibility. It is often used for implants such as orthopedic devices, cardiovascular stents, and dental implants.

- Q: What are the common applications for stainless steel strips?

- Stainless steel strips are widely used in various industries due to their unique properties and versatility. Some common applications for stainless steel strips include: 1. Automotive industry: Stainless steel strips are used to manufacture automotive components like exhaust systems, trim, and decorative elements. They offer corrosion resistance and high strength, making them ideal for withstanding harsh environments and ensuring durability. 2. Construction industry: Stainless steel strips are frequently used in construction projects for architectural purposes, such as cladding, roofing, and façades. Their aesthetic appeal, corrosion resistance, and low maintenance requirements make them a popular choice for modern buildings. 3. Kitchen appliances: Stainless steel strips are commonly used in the production of kitchen appliances like refrigerators, dishwashers, and ovens. They provide a sleek and hygienic surface, resistance to stains, and ease of cleaning, making them a preferred material in the food industry. 4. Medical equipment: Stainless steel strips are extensively used in the medical field for manufacturing surgical instruments, implants, and diagnostic equipment. Their biocompatibility, resistance to corrosion, and sterilization capabilities make them indispensable in healthcare settings. 5. Electronics industry: Stainless steel strips are employed in electronic devices, particularly for shielding purposes. They provide electromagnetic interference (EMI) protection and are used in electronic enclosures and connectors. 6. Aerospace and aviation: Stainless steel strips are used in the aerospace industry for various applications, including aircraft components, engine parts, and structural elements. They offer high strength, heat resistance, and corrosion resistance, ensuring safety and reliability in extreme conditions. 7. Energy sector: Stainless steel strips are utilized in the energy industry for manufacturing components in power plants, oil and gas pipelines, and renewable energy systems. Their resistance to high temperatures, corrosion, and mechanical stress make them suitable for these demanding environments. Overall, stainless steel strips find extensive use in a wide range of applications due to their exceptional properties, including corrosion resistance, strength, durability, and aesthetic appeal.

- Q: How does stainless steel strip perform in corrosive environments?

- Stainless steel strip performs exceptionally well in corrosive environments. Due to its high chromium content, stainless steel forms a protective oxide layer on its surface when exposed to oxygen, which prevents the material from further corrosion. This oxide layer acts as a barrier against corrosive elements such as moisture, chemicals, and saltwater, providing stainless steel strip with excellent resistance to corrosion. Furthermore, stainless steel strip exhibits superior corrosion resistance to various acids, alkaline solutions, and organic compounds, making it an ideal choice for applications in industries such as chemical processing, food processing, and marine environments. Its resistance to pitting corrosion and crevice corrosion further enhances its performance in corrosive environments. In addition to its corrosion resistance, stainless steel strip also possesses other beneficial properties such as high strength, durability, and heat resistance, making it a reliable material for a wide range of applications. Whether used for manufacturing equipment, components, or structures, stainless steel strip offers long-lasting performance, even in harsh and corrosive conditions.

- Q: Can stainless steel strips be plated or coated with another metal?

- Yes, stainless steel strips can be plated or coated with another metal. This process, known as electroplating or coating, involves applying a thin layer of a different metal onto the stainless steel surface. This is often done to improve the appearance, corrosion resistance, or other properties of the stainless steel strips.

- Q: What is the coefficient of expansion for stainless steel strips?

- The coefficient of expansion for stainless steel strips varies according to the particular grade and composition of the stainless steel. On average, the linear expansion coefficient for stainless steel is approximately 17-19 x 10^-6 per degree Celsius. It is crucial to bear in mind that various types of stainless steel may possess slightly dissimilar expansion coefficients, thus it is always advisable to refer to the manufacturer's specifications for the specific grade of stainless steel being utilized.

Send your message to us

Stainless Steel Coil Cold Rolled 201 Half Cu 0.8 Prime Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords