201, 202,301, 304, 316,304L,316L,309,410,430 Stainless Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

201, 202,301, 304, 316,304L,316L,309,410,430 Stainless Steel Coil

Thickness:0.1-120mm

Width:1000-2000mm

Length: As required

Typical physical properties for stainless steel coil

Grade | Chemical composition | ||||||

C | Si | Mn | P | S | Ni | Cr | |

% | % | % | % | % | % | % | |

309S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.04 | ≤0.030 | 12.00-15.00 | 22.00-24.00 |

Item | 201, 202,301, 304,316,304L,316L,309,410,430 Stainless Steel Coil |

Technical | Hot rolled and cold rolled |

Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,GB/T3280-2007,EN10095-99,JIS4312,etc |

Material | 201, 202,301, 304,316,304L,316L,309,410,430 |

Surface | NO.1,2B, mirror finish,4K,8K,Hairline finish |

Thickness | 0.1-120mm |

Width | 1000-2000mm |

Price term | FOB,CFR,CIF,CNF |

Application | Stainless steel coil applies to construction field, ships building industry, petroleum, chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Stainless steel coil can be made according to the customer’s requirements. |

Contact | If you have any question, please feel free to contact me. |

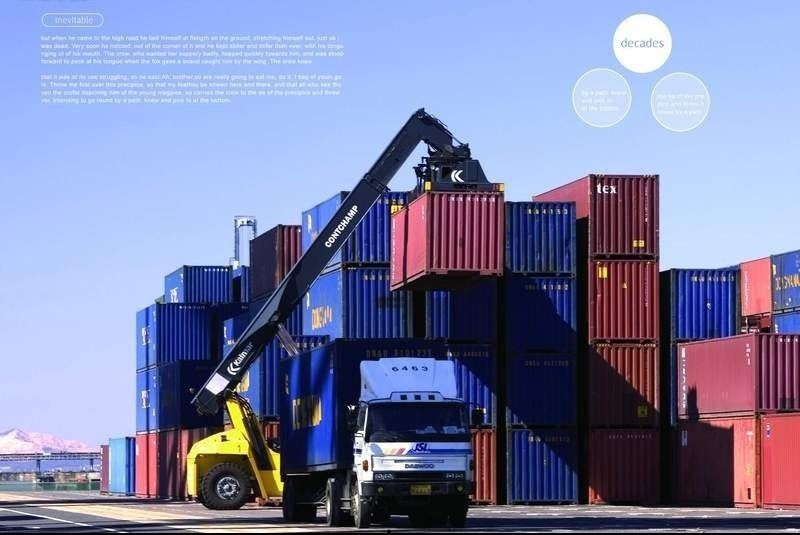

Packaging & shipping

Standard export seaworthy packing (with waterproof paper, metal belt pack sheet,

then put them in wooden pallet, then put in container) or customized.

Products are packed and labeled according to the regulations and customer's request.

Grate car is taken to avoid any damage which might otherwise be caused during storage

or transportation. In addition, clear labels are tagged on the otside of the packages

for easy identification of the product I.D. and quality information.

20 ft - GP: 5.8m (Length) * 2.13m (Width) * 2.18m (Hight) ------ About 23MTS

40 ft - GP: 11.8m (Length) * 2.13m (Width) * 2.18m (Hight) ------ About 27MTS

40 ft - HG: 11.8m (Length) * 2.13m (Width) * 2.72m (Hight) ------ About 27MTS

Production Machines

Application

Applications of Stainless Steel Coil:

1.Automotive: Automotive trim and molding/Difficult-to-form exhaust-system components, tubular manifolds, mufflers/Exhaust manifold and other exhaust-system components, catalytic converter shells, clamps

2. Construction: Gutters and downspouts, roofing, siding

3. Kitchenware: Cooking utensils, dishwashers, ovens, range hoods, refrigerators, skewers 4.Chemical processing: Oil refinery equipment, oil burner and heater parts

5. Appliances: Hot water tanks, residential furnaces

6. Power generation: Heat Exchanger tubing

7. Farming: Dry fertilizer spreaders/Farm animal pens

FAQ

why choose us?

1. All products are made of high-quality imported raw materials.

2. Our product passed SGS,BV,ISO certifications etc.

3. We are nominated as the AAA enterprise .

4. High corrosion resistant

5. Quickest and most efficient Response to Your Enquiry.

6..Stocked products and prompt delivery

7.Multiple payment terms

8.We offer competitive price(high quality)with best service

9.We have high technical production line

10.We have win high reputation based on best quality products

- Q: What is the composition of 111 stainless steel strips?

- The specific alloy used to manufacture these 111 stainless steel strips is typically known as the composition. Stainless steel, an iron-based alloy, is composed of at least 10.5% chromium along with other elements such as nickel, molybdenum, manganese, and carbon. The composition of these 111 stainless steel strips may vary depending on the grade or specification. For instance, a commonly used grade is 304 stainless steel, which typically contains 18% chromium and 8% nickel. Another frequently utilized grade is 316 stainless steel, which consists of 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. To ascertain the exact composition of these 111 stainless steel strips, it is necessary to refer to the manufacturer or supplier's specific grade or specification.

- Q: What are the recommended cleaning agents for 111 stainless steel strips?

- The recommended cleaning agents for 111 stainless steel strips include mild soaps, non-abrasive cleaners, and specialized stainless steel cleaners. It is important to avoid using harsh chemicals, abrasive scrubbers, and chlorine-based cleaners as they may damage the stainless steel surface.

- Q: Can stainless steel strips be used in outdoor applications?

- Certainly! Outdoor applications can utilize stainless steel strips. Due to its exceptional resistance to corrosion, stainless steel is an excellent choice for outdoor environments that may encounter moisture, humidity, and other elements. Moreover, stainless steel possesses remarkable durability and strength, making it suitable for a range of outdoor applications, including construction, signage, and equipment. Regardless of whether stainless steel strips are employed for decorative purposes or functional use, they are capable of withstanding harsh outdoor conditions and delivering long-lasting performance.

- Q: Are stainless steel strips suitable for cryogenic storage?

- Yes, stainless steel strips are suitable for cryogenic storage. Stainless steel has excellent low-temperature properties, including high strength, corrosion resistance, and thermal stability, making it a suitable material for storing materials at extremely low temperatures commonly found in cryogenic applications.

- Q: What are the typical hardness values of stainless steel strips?

- Depending on the specific grade and type of stainless steel, the typical hardness values of stainless steel strips can vary. Generally, stainless steel strips have a hardness range of 150 to 250 on the Vickers hardness scale (HV). Certain grades of stainless steel may exhibit higher hardness values, exceeding 300 HV or even more, whereas others may have lower hardness values, approaching the lower end of the range. Additionally, it is worth noting that factors such as the heat treatment process and the strip thickness can also influence the hardness of stainless steel strips.

- Q: Can stainless steel strips be used in mining applications?

- Yes, stainless steel strips can be used in mining applications. Stainless steel is known for its high strength, corrosion resistance, and durability, making it suitable for use in harsh mining environments. Stainless steel strips can be used in various mining equipment and machinery, including conveyor systems, screens, crushers, and tanks, to name a few. They are often used in mining operations where there is exposure to moisture, chemicals, and abrasive materials. The corrosion resistance of stainless steel helps prevent rust and deterioration, ensuring the longevity and performance of mining equipment. Additionally, stainless steel strips can withstand high temperatures and harsh conditions commonly found in mining applications. Therefore, stainless steel strips are a reliable choice for use in mining operations.

- Q: Are stainless steel strips suitable for conveyor systems?

- Yes, stainless steel strips are highly suitable for conveyor systems. Stainless steel is known for its excellent corrosion resistance, durability, and strength, making it an ideal material for conveyor systems that require continuous operation and exposure to various environmental conditions. Stainless steel strips can withstand high temperatures, moisture, chemicals, and abrasive materials, ensuring a long lifespan and minimal maintenance requirements. Additionally, stainless steel strips have a smooth surface, which reduces friction and allows for efficient material movement on the conveyor. This makes stainless steel strips a preferred choice in industries such as food processing, pharmaceuticals, automotive, and manufacturing, where cleanliness, hygiene, and product integrity are crucial. Overall, stainless steel strips offer reliability, longevity, and performance, making them well-suited for conveyor systems.

- Q: What are the factors affecting the hardness of 111 stainless steel strips?

- The hardness of 111 stainless steel strips can be influenced by multiple factors. These factors include the alloy composition, the heat treatment process, cold working, grain size, the presence of impurities, work hardening, and the surface finish. 1. Alloy composition plays a significant role in determining the hardness of stainless steel. The presence of elements like chromium, nickel, and manganese can have a direct impact on hardness. Higher levels of these elements generally result in increased hardness. 2. The heat treatment process is crucial in determining the hardness of stainless steel. Processes such as annealing, quenching, and tempering can be used to manipulate the microstructure of the steel, which in turn affects its hardness. 3. Cold working, also known as cold rolling or cold drawing, involves deforming the stainless steel at room temperature. This process induces dislocations and strain hardening, significantly increasing the hardness of the material. 4. Grain size is another factor that influences the hardness of stainless steel. Finer grain sizes typically result in higher hardness due to the increased number of grain boundaries, which impede dislocation movement. 5. The presence of impurities, such as sulfur and phosphorus, can have a detrimental effect on the hardness of stainless steel. These impurities can promote the formation of non-metallic inclusions, ultimately reducing the material's hardness. 6. Work hardening occurs during the manufacturing process of stainless steel strips. It refers to the increase in hardness that happens as a result of plastic deformation. The level of work hardening depends on factors such as the amount of deformation, strain rate, and the initial hardness of the material. 7. The surface finish of stainless steel strips can impact their hardness. Factors like surface roughness and the presence of residual stress can influence the distribution and behavior of dislocations, thus affecting the material's hardness. It is important to note that the specific combination and interaction of these factors may vary depending on the manufacturing process, alloy type, and intended application of the stainless steel strips. Therefore, a comprehensive understanding of these factors is necessary to effectively control and optimize the hardness of 111 stainless steel strips.

- Q: Are stainless steel strips resistant to caustic soda corrosion?

- Generally, stainless steel strips are resistant to corrosion caused by caustic soda. Stainless steel is renowned for its outstanding resistance to corrosion, making it widely utilized in various industries that may expose it to caustic soda or other corrosive chemicals. However, the extent of stainless steel's resistance to corrosion relies on the specific grade or alloy employed. Certain grades of stainless steel, like 316 and 317, exhibit exceptional resistance to corrosion caused by caustic soda due to their elevated levels of chromium and molybdenum. To ensure the most suitable grade of stainless steel is utilized for a particular application involving caustic soda, it is always advisable to seek guidance from a stainless steel expert or consult specific material data sheets.

- Q: Are stainless steel strips suitable for architectural cladding?

- Architectural cladding can benefit from the use of stainless steel strips. This material is known for its versatility and durability, making it a suitable choice for this purpose. One advantage of stainless steel is its excellent resistance to corrosion, which makes it well-suited for outdoor applications. It can withstand challenging weather conditions, moisture, and exposure to chemicals, ensuring that the cladding remains strong and durable over time. Another advantage of stainless steel is its sleek and modern appearance, which adds an aesthetic appeal to buildings. It can be finished in different ways, such as brushed, polished, or embossed, allowing architects and designers to achieve various visual effects and styles. Furthermore, stainless steel strips come in a wide range of sizes, thicknesses, and shapes, providing flexibility in design and installation. They can be easily cut, formed, and welded to fit specific architectural requirements, making them suitable for both large-scale projects and intricate detailing. Moreover, stainless steel is a low-maintenance material that requires minimal upkeep. It is resistant to staining, scratching, and fading, reducing the need for frequent cleaning or repairs. This characteristic makes it a cost-effective choice for architectural cladding. In conclusion, stainless steel strips offer several advantages for architectural cladding, including corrosion resistance, aesthetic appeal, versatility, and low-maintenance properties. They provide architects and designers with a reliable and visually appealing solution for enhancing the exterior of buildings.

Send your message to us

201, 202,301, 304, 316,304L,316L,309,410,430 Stainless Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords