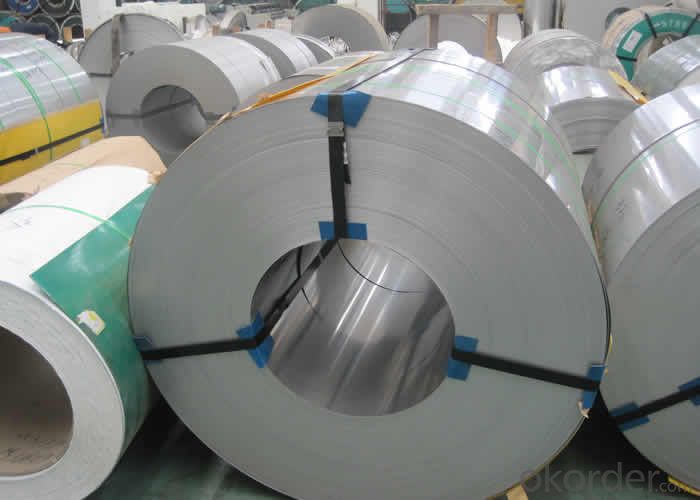

Stainless Steel Coil 201 Surface No.1 Hot Rolled Coil

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Stainless Steel Coil 201 Narrow Strip No.1 Finish

Hot Rolled Stainless Steel 201 half copper Chemical Composition(%) | |||||||

C | Si | Mn | P | S | Ni | Cr | Cu |

0.1 | 0.5 | 10 | 0.04 | 0.01 | 1.20/1.30 | 13.00/14.00 | 0.8/1.0 |

Grade: | 200 Series | Standard: | JIS,AISI,ASTM,GB,DIN | Thickness: | 2.5/3.0/4.0mm |

Width: | 485/510/550/610/1010/1240mm | Place of Origin: | Shanghai China (Mainland) | Brand Name: | CNBM |

Model Number: | 201 | Technique: | Hot Rolled | Application: | Industrial tubes/kitchen/bath |

Certification: | ISO | THK: | 2.5/3.0/4.0mm | Face: | No.1 |

Usage: | tubes/kitchen/bath | Origin: | CHINA | ||

Packaging Detail: For customer's requirement

Delivery Detail: 10-30days

201 Hot Rolled Stainless Steel Coil Specifications

THK:2.3/2.5/3.0/4.0mm

Width:485/510/550/610/1010/1240mm

Face:No.1

201 Hot rolled stainless steel Coil Application

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry. 201 hot rolled stainless steel coil, use to produce cold rolled stainless steel coil and stainless steel tube, pipe.

201 Hot Stainless Steel Coil Chemical Composition(WT%)

(C):≤0.15, (Si):≤0.75, (Mn):5.5~7.50, (Cr):16.0~18.0, (N):≤0.25, (Ni):3.50~5.50, (P):≤0.060, (S):≤0.030

201 Hot Rolled Stainless Steel Coil

Strength Of Extension:100,000 To 180,000 Psi;

Yield Strength:50,000 To 150,000 Psi

Elongation :55 To 60%;

Modulus Of Elasticity:29,000,000 Psi;

Density :.280lbs/Cubic Inch(7.93g/Cm3)

- Q: What is the creep strength of stainless steel strips?

- The ability of stainless steel strips to withstand long-term deformation under elevated temperatures and constant load is referred to as the creep strength. Stainless steel is well-known for its exceptional resistance to creep due to its high alloy content and specific microstructure. Various factors, including alloy composition, heat treatment, and grain size, influence the creep strength of stainless steel strips. Compared to other materials, stainless steel strips generally display high creep strength, particularly at elevated temperatures. The inclusion of elements like chromium, nickel, and molybdenum enhances the creep resistance of stainless steel, enabling it to maintain its shape and structural integrity over extended periods of constant load. Moreover, the heat treatment process plays a crucial role in optimizing the creep strength of stainless steel strips. Employing appropriate techniques such as annealing or solution treatment followed by aging can enhance the material's microstructure and minimize the formation of detrimental phases like sigma phase, which can diminish creep resistance. The grain size of stainless steel also impacts its creep strength. Fine-grained stainless steel strips tend to exhibit superior creep resistance compared to those with coarse grains. This is because fine grains impede the movement of dislocations, which are responsible for creep deformation. Overall, stainless steel strips possess relatively high creep strength, making them well-suited for applications that require resistance to long-term deformation and high temperatures, such as in the power generation, aerospace, and chemical processing industries.

- Q: How long do stainless steel strips typically last?

- Stainless steel strips exhibit exceptional durability and resistance to corrosion, rendering them an optimal choice for a wide range of applications. The lifespan of these strips hinges on several factors, including the type of stainless steel employed, environmental circumstances, maintenance practices, and the specific application. In general, stainless steel strips boast an extended lifespan that can span decades or even longer. This is attributed to their remarkable resistance to rust and corrosion, the primary culprits responsible for the deterioration and reduced longevity of other metals. The corrosion resistance of stainless steel stems from its chromium content, which forms a thin, protective layer on its surface, effectively preventing rust formation. The specific grade of stainless steel used significantly influences its lifespan. Different grades exist, each comprising varying levels of chromium and other alloying elements. Higher grades, like 316 or 304 stainless steel, provide enhanced corrosion resistance and are commonly employed in demanding settings such as marine applications or highly corrosive industrial environments. Consequently, these superior-grade stainless steel strips often surpass their lower-grade counterparts in terms of durability and longevity. Environmental conditions also impact the lifespan of stainless steel strips. In harsh, corrosive environments such as coastal areas with high salt content in the air or industrial settings with exposure to chemicals, more frequent maintenance or protective coatings may be necessary to extend the strips' lifespan. Similarly, adhering to proper maintenance practices such as regular cleaning and the removal of corrosive substances can significantly prolong the lifespan of stainless steel strips. All in all, stainless steel strips are renowned for their exceptional longevity and can typically endure for numerous years, even in demanding conditions. With adequate care and maintenance, these strips provide a durable and dependable solution for various applications, making them a favored choice across diverse industries.

- Q: Can stainless steel strips be used in heat recovery systems?

- Yes, stainless steel strips can be used in heat recovery systems. Stainless steel has excellent heat resistance properties, making it suitable for applications where high temperatures are involved. Its durability, corrosion resistance, and ability to withstand thermal cycling make it a popular choice for heat recovery systems that require efficient heat transfer and long-term reliability.

- Q: Are stainless steel strips suitable for chemical pipes?

- Yes, stainless steel strips are suitable for chemical pipes. Stainless steel is highly resistant to corrosion and can withstand the corrosive effects of various chemicals, making it a suitable material for constructing chemical pipes.

- Q: Can stainless steel strips be used in the production of oil and gas storage tanks?

- Indeed, oil and gas storage tanks can benefit from the utilization of stainless steel strips. Possessing a multitude of advantageous properties, stainless steel emerges as a versatile and long-lasting substance that exhibits exceptional resistance against corrosion. Consequently, it is deemed appropriate for deployment in demanding surroundings like oil and gas storage tanks. Notably, its elevated strength-to-weight ratio and capacity to withstand temperature fluctuations render it an optimal selection for these particular purposes. Moreover, stainless steel's effortless cleanability and maintenance contribute to the durability and dependability of the storage tanks.

- Q: Are stainless steel strips resistant to stress corrosion cracking?

- Generally, stainless steel strips are resistant to stress corrosion cracking. The presence of chromium in stainless steel creates a protective oxide layer on the metal's surface, which acts as a barrier against corrosive elements like chloride ions that often cause stress corrosion cracking. However, it is important to note that the resistance to stress corrosion cracking can vary depending on the specific grade of stainless steel and the environment it is exposed to. Austenitic stainless steels, such as 304 and 316, have excellent resistance to stress corrosion cracking in most environments. Nevertheless, in aggressive environments with high concentrations of chloride ions or high-stress conditions, even stainless steel can be susceptible to stress corrosion cracking. In such cases, using higher alloyed grades of stainless steel or applying additional corrosion prevention methods may be necessary for optimal resistance to stress corrosion cracking. Overall, stainless steel strips are generally highly resistant to stress corrosion cracking, making them a reliable choice for various applications in corrosive environments.

- Q: Can stainless steel strips be used in kitchenware?

- Yes, stainless steel strips can be used in kitchenware. Stainless steel is a popular choice for kitchenware due to its durability, resistance to corrosion, and ease of cleaning. Stainless steel strips can be used to make various kitchen utensils, cookware, and appliances, making them a suitable material for kitchenware applications.

- Q: Can 111 stainless steel strips be used in marine environments?

- Yes, 111 stainless steel strips can be used in marine environments. 111 stainless steel is a low carbon, high chromium stainless steel that offers excellent resistance to corrosion in various environments, including marine environments. It has good strength and toughness, making it suitable for use in marine applications such as boat fittings, marine hardware, and offshore structures. Additionally, 111 stainless steel has good weldability and can withstand exposure to saltwater and other corrosive elements commonly found in marine environments. However, it is important to properly maintain and clean the stainless steel strips to ensure their long-term performance in marine environments.

- Q: Can stainless steel strips be used in chemical reactors?

- Certainly, chemical reactors can utilize stainless steel strips. The chemical industry extensively employs stainless steel owing to its remarkable resistance to corrosion. Its ability to withstand diverse chemicals, such as acids, bases, and organic solvents, renders it suitable for application in chemical reactors. Stainless steel strips can be transformed into different forms and sizes to cater to the precise demands of a chemical reactor. Furthermore, stainless steel's exceptional strength and durability make it a perfect choice for enduring the harsh circumstances and pressures typically encountered in chemical procedures.

- Q: How do you select the right grade of stainless steel strip for a specific application?

- To select the right grade of stainless steel strip for a specific application, several factors must be considered. These factors include the corrosive environment, temperature range, mechanical requirements, and the desired appearance or finish. It is crucial to evaluate the chemical composition, corrosion resistance, strength, and ductility of different stainless steel grades to ensure they meet the specific needs of the application. Additionally, consulting with experts and conducting thorough research on the various grades available can aid in making an informed decision.

Send your message to us

Stainless Steel Coil 201 Surface No.1 Hot Rolled Coil

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords