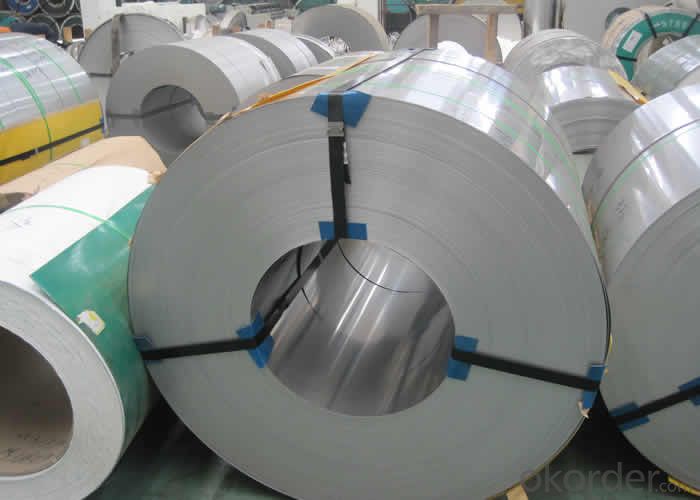

Stainless Steel Coil 201 Hot Rolled Coil Narrow Coil

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Stainless Steel Coil 201 Narrow Strip No.1 Finish

Packaging Detail: For customer's requirement

Delivery Detail: 10-30days

201 Hot Rolled Stainless Steel Coil Specifications

THK: 2.3/2.5/3.0/4.0mm

Width: 485/510/550/610/1010/1240mm

Face: No.1

201 Hot rolled stainless steel Coil Application

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry.

201 Hot Stainless Steel Coil Chemical Composition(WT%)

(C):≤0.15, (Si):≤0.75, (Mn):5.5~7.50, (Cr):16.0~18.0, (N):≤0.25, (Ni):3.50~5.50, (P):≤0.060, (S):≤0.030

201 Hot Rolled Stainless Steel Coil

Strength Of Extension:100,000 To 180,000 Psi

Yield Strength:50,000 To 150,000 Psi

Elongation :55 To 60%

Modulus Of Elasticity:29,000,000 Psi

Density :.280lbs/Cubic Inch(7.93g/Cm3)

- Q: Are stainless steel strips resistant to staining?

- Stainless steel strips exhibit remarkable resistance to staining. The exceptional corrosion resistance and stain-proof nature of stainless steel make it renowned. It can endure staining from a wide range of substances, including food, liquids, and chemicals. This is attributed to the presence of chromium in stainless steel, which generates a safeguarding layer on the surface, preventing both staining and corrosion. However, it is crucial to acknowledge that stainless steel may also stain or corrode in specific circumstances, such as when exposed to harsh chemicals or excessive humidity levels. Consistent cleaning and maintenance are imperative for preserving the stain resistance of stainless steel strips and ensuring they maintain their pristine appearance.

- Q: How do you prevent rust on stainless steel strips?

- To prevent rust on stainless steel strips, there are several steps you can take: 1. Keep them clean: It's crucial to regularly clean stainless steel strips to remove dirt, debris, and contaminants that could cause rust. Use a mild detergent or stainless steel cleaner and a soft cloth or sponge to thoroughly clean the surface. Avoid abrasive cleaners or scrub brushes, as they can scratch the stainless steel and make it more prone to rusting. 2. Ensure they are dry: After cleaning, make sure to completely dry the stainless steel strips. Moisture can contribute to rust formation, so use a clean, dry cloth to wipe away any remaining moisture. Pay close attention to areas where water can accumulate, like crevices or corners. 3. Protect them from chemicals and corrosive substances: While stainless steel is resistant to corrosion, certain chemicals or substances can still cause damage or rusting. Avoid exposing the strips to harsh chemicals, like bleach or ammonia-based cleaners, as they can corrode the surface. If they do come into contact with corrosive substances, rinse them immediately with water and dry thoroughly. 4. Apply protective coatings: Adding a protective coating, such as clear lacquer or a special stainless steel protective spray, can create a barrier between the stainless steel and external factors that could cause rust. These coatings provide an extra layer of protection and help maintain the appearance and durability of the strips. 5. Limit exposure to saltwater or high humidity: Stainless steel can be more prone to rusting in environments with high humidity or exposure to saltwater. If possible, minimize the exposure of the stainless steel strips to these conditions. If avoiding such environments is not possible, taking extra precautions, like more frequent cleaning and using appropriate protective coatings, becomes even more important. By following these preventive measures, you can significantly reduce the risk of rust formation on stainless steel strips and ensure their longevity and visual appeal.

- Q: What are the common uses of stainless steel strips in the oil and gas pipeline industry?

- Stainless steel strips are commonly used in the oil and gas pipeline industry for various applications such as corrosion resistance, high strength, durability, and heat resistance. These strips are used for manufacturing pipeline components like valves, flanges, fittings, and connectors, as well as for constructing storage tanks and offshore platforms. Their resistance to harsh environments and ability to withstand high pressure and temperature make stainless steel strips a preferred choice in the oil and gas industry.

- Q: Are stainless steel strips suitable for heat treatment processes?

- Yes, stainless steel strips are suitable for heat treatment processes. Heat treatment can help improve the mechanical properties, such as hardness and strength, of stainless steel strips. Different heat treatment processes, such as annealing, tempering, and quenching, can be used to achieve specific material properties and desired outcomes in stainless steel strips.

- Q: How do stainless steel strips handle exposure to caustic solutions?

- Stainless steel strips possess remarkable corrosion resistance, which makes them highly appropriate for applications involving contact with caustic solutions. This attribute is attributed to the abundance of chromium in stainless steel, which results in the formation of a protective layer called a passive film on its surface. This passive film acts as a barrier, preventing direct contact between the steel and the caustic solutions, thus reducing the possibility of corrosion. Caustic solutions, such as strong alkaline substances or highly acidic solutions, have the potential to cause corrosion or damage to many other metals. However, stainless steel's resistance to corrosion allows it to withstand exposure to caustic solutions fairly well. The passive film on the surface of stainless steel is stable and has the ability to self-heal. This means that if it becomes damaged or scratched, it has the capability to regenerate and continue providing effective protection against corrosion. It is crucial to note that the resistance of stainless steel strips to caustic solutions may vary depending on the specific grade or alloy used. Different grades of stainless steel offer different levels of corrosion resistance, and some may be more suitable for certain caustic solutions than others. Therefore, it is of utmost importance to select the appropriate grade of stainless steel based on the specific application and the type of caustic solution it will be exposed to. To summarize, stainless steel strips generally exhibit good resistance to caustic solutions due to their inherent corrosion resistance. However, it is essential to choose the correct grade of stainless steel to ensure optimal performance and durability in corrosive environments.

- Q: How do stainless steel strips compare to other materials?

- When comparing stainless steel strips to other materials, they stand out for several reasons. Firstly, stainless steel is renowned for its exceptional resistance to corrosion. This characteristic makes it the perfect choice for applications that involve exposure to moisture, chemicals, or harsh environments. Unlike other materials, stainless steel does not easily rust or stain, ensuring durability and longevity. Secondly, stainless steel strips exhibit outstanding strength and toughness. They possess a high tensile strength, enabling them to withstand heavy loads and resist deformation under stress. This quality makes stainless steel strips suitable for applications that require structural integrity and reliability. Another notable advantage of stainless steel strips lies in their aesthetic appeal. Stainless steel has a sleek and modern appearance that can enhance the visual appeal of any project or product. It is commonly utilized in architecture and interior design due to its clean and contemporary look. Moreover, stainless steel strips offer exceptional versatility. They can be easily formed, welded, and fabricated into various shapes and sizes to meet specific requirements. This flexibility allows stainless steel strips to be utilized across a wide range of industries, including construction, automotive, aerospace, and manufacturing. Lastly, stainless steel is a sustainable and environmentally friendly material. It is 100% recyclable, making it an excellent choice for projects with a focus on sustainability. Additionally, stainless steel has a long lifespan, reducing the need for frequent replacements and minimizing waste. In conclusion, stainless steel strips excel in terms of corrosion resistance, strength, aesthetic appeal, versatility, and sustainability when compared to other materials. These characteristics make stainless steel a top-notch choice for numerous applications in various industries.

- Q: How do stainless steel strips resist erosion in abrasive environments?

- Stainless steel strips are highly resistant to erosion in abrasive environments due to their unique composition and properties. The primary factor that enables stainless steel strips to resist erosion is the presence of chromium in the alloy. Chromium forms a thin, invisible layer of chromium oxide on the surface of the steel, which acts as a protective barrier against corrosion and erosion. This chromium oxide layer is extremely stable and adheres tightly to the steel surface, preventing any further oxidation or corrosion from occurring. It effectively seals the steel from the surrounding environment, including abrasive particles, moisture, and other contaminants that could cause erosion. Additionally, stainless steel strips often contain other alloying elements such as nickel and molybdenum, which further enhance their resistance to erosion. These elements contribute to the formation of a passive film that provides an additional layer of protection against abrasion. Furthermore, stainless steel strips are typically engineered to possess a high hardness and strength, making them more resistant to mechanical wear and tear. They can withstand the impact and friction caused by abrasive particles without significant damage or erosion. Moreover, the smooth surface finish of stainless steel strips reduces the likelihood of particles getting trapped or lodged in microscopic crevices, minimizing the potential for erosion. This smoothness also facilitates easy cleaning and maintenance, ensuring the longevity of the stainless steel strips in abrasive environments. In summary, stainless steel strips resist erosion in abrasive environments primarily through the formation of a protective chromium oxide layer, their high hardness and strength, and their smooth surface finish. These factors work together to provide excellent resistance against corrosion, mechanical wear, and the detrimental effects of abrasive particles.

- Q: Are stainless steel strips resistant to hydrochloric acid?

- Yes, stainless steel strips are generally resistant to hydrochloric acid. This is because stainless steel is known for its corrosion resistance and ability to withstand chemical attack. However, the level of resistance can vary depending on the grade of stainless steel used. Higher grades of stainless steel, such as 316 or 317, have a higher resistance to hydrochloric acid compared to lower grades like 304 or 430. It is important to note that prolonged exposure or contact with concentrated hydrochloric acid can still cause some corrosion or pitting in stainless steel, but it is generally considered to be one of the most resistant metals to this acid.

- Q: Can stainless steel strips be painted or coated?

- Yes, stainless steel strips can be painted or coated.

- Q: Can stainless steel strips be stamped or engraved?

- Yes, stainless steel strips can be stamped or engraved.

Send your message to us

Stainless Steel Coil 201 Hot Rolled Coil Narrow Coil

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords