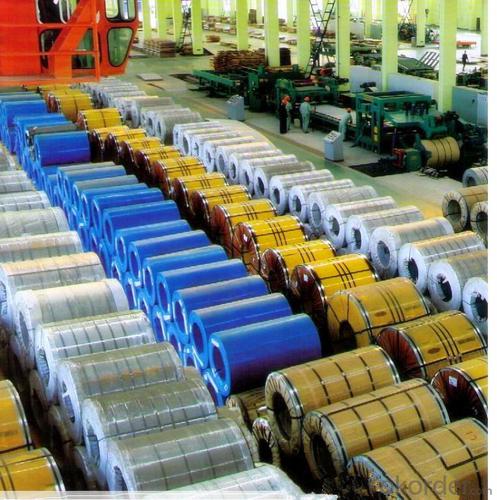

Stainless Steel Coil 304 Surface No.1 Hot Rolled Coil

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Stainless Steel Coil 304 Annealing and Pickling No.1 Finish

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry.

Hot Rolled Stainless Steel Coil 304 Specifications

1.surface:NO.1

2.standard:JIS, AISI, GB

3.width: 0.55m, 0.65m, 1.0m, 1.22m, 1.5m, 2m or requirement

Hot Rolled Stainless Steel Coil 304 Chemical Composition:

(%):C=0.07, Mn=2.00, P=0.045, S=0.030, Si=0.075, Cr=17.5-19.5, Ni=8.0-10.5, N=0.10

Hot Rolled Stainless Steel Coil 304 Physical Properties

Tensile strength σb (MPa) ≥ 520

the conditions yield strength σ0.2 (MPa) ≥ 205,

elongation δ5 (%) ≥ 40

Reduction of ψ (%) ≥ 50,

hardness: ≤ 187

HB; ≤ 90

HRB; ≤ 200H

- Q: What is the composition of 111 stainless steel strips?

- The composition of 111 stainless steel strips typically refers to the specific alloy used to manufacture these strips. Stainless steel is an iron-based alloy that contains a minimum of 10.5% chromium. In addition to chromium, stainless steel may also contain other elements such as nickel, molybdenum, manganese, and carbon. The exact composition of 111 stainless steel strips can vary depending on the specific grade or specification. For example, a common grade is 304 stainless steel, which typically consists of 18% chromium and 8% nickel. Another commonly used grade is 316 stainless steel, which contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. To determine the precise composition of 111 stainless steel strips, it would be necessary to refer to the specific grade or specification provided by the manufacturer or supplier.

- Q: Can stainless steel strips be bent or formed?

- Yes, stainless steel strips can be bent or formed. Stainless steel is a highly malleable material, which means it can be easily shaped or bent into various forms. This flexibility makes it a popular choice in many industries, including construction, automotive, and manufacturing. Stainless steel strips can be bent or formed using various techniques such as cold bending, roll forming, or press braking. The specific method used depends on the desired shape and the thickness of the stainless steel strip. However, it is important to note that the bending or forming process may require specialized equipment and expertise to ensure proper and accurate results.

- Q: What are the different surface treatments available for stainless steel strips?

- Stainless steel strips offer a range of surface treatments, each with its own advantages and characteristics. Let's explore some of the most common options: 1. The standard untreated surface of stainless steel strips is called Mill Finish. It has a smooth and shiny appearance, perfect for those who prefer a natural, unaltered look. 2. Another popular treatment is the Brushed Finish, also known as satin finish. This involves brushing the surface with abrasive materials to create a matte texture. It not only adds a stylish touch but also helps to conceal scratches and fingerprints. 3. For a highly reflective surface, there is the Mirror Finish. Achieved through progressive polishing with finer abrasives, it creates a mirror-like appearance. 4. If you're looking for decorative patterns, the Patterned Finish is the way to go. This treatment involves embossing, etching, or laser engraving to achieve various designs and textures. 5. PVD Coating, or Physical Vapor Deposition coating, offers a thin layer of metallic or non-metallic material applied through a vacuum deposition process. This not only provides enhanced durability and corrosion resistance but also allows for different colors or a metallic appearance. 6. Passivation is a chemical treatment that removes iron contaminants from the surface, improving corrosion resistance. It utilizes acid-based solutions to clean and neutralize the stainless steel strips. 7. Electropolishing involves the removal of a thin layer of metal using an electric current. This treatment results in a smooth and shiny surface, enhances corrosion resistance, and eliminates embedded contaminants. 8. Lastly, stainless steel strips can be coated with materials like paint, epoxy, or polymers for additional protection against corrosion, abrasion, or for aesthetic purposes. These examples showcase the diverse range of surface treatments available for stainless steel strips. The choice of treatment depends on specific requirements such as desired appearance, corrosion resistance, durability, and functionality.

- Q: What are the recommended safety guidelines for cutting 111 stainless steel strips?

- The recommended safety guidelines for cutting 111 stainless steel strips include wearing appropriate personal protective equipment such as safety goggles, gloves, and a face shield to protect against potential flying metal shards. It is also important to use a sharp cutting tool specifically designed for stainless steel, and to apply steady pressure and avoid excessive force while cutting. Additionally, working in a well-ventilated area or using local exhaust ventilation can help minimize exposure to fumes and dust. It is crucial to follow proper handling and storage procedures for the steel strips, and to consult manufacturer guidelines or seek professional assistance if needed.

- Q: What are the common uses of stainless steel strips in the pharmaceutical packaging industry?

- The pharmaceutical packaging industry relies on stainless steel strips for various purposes. One primary use involves the manufacturing of packaging containers and components. Different types of containers, including vials, ampoules, and syringes, are made from stainless steel strips due to their ability to resist corrosion, withstand high temperatures, and maintain sterility. By choosing stainless steel, the industry ensures the safety and integrity of the packaged drugs. Moreover, stainless steel strips are also employed in the production of packaging components like lids, caps, and closures. These components are crucial in preserving the quality and freshness of pharmaceutical products. Stainless steel's resistance to rust and its ability to create an airtight seal are essential in guaranteeing the integrity of the packaged medications. Additionally, stainless steel strips find use in constructing pharmaceutical machinery and equipment. The manufacturing processes often involve heavy machinery that requires durable and corrosion-resistant materials. Stainless steel strips are frequently used to fabricate machine parts, conveyor systems, and packaging equipment, ensuring their longevity and reliability. Another common application of stainless steel strips in the pharmaceutical packaging industry is for labeling and identification purposes. Important information such as batch numbers, expiration dates, and drug identification codes can be engraved or etched onto stainless steel strips. This ensures accurate tracking, tracing, and identification of the pharmaceutical products throughout the packaging and distribution process. In summary, stainless steel strips offer numerous advantages in the pharmaceutical packaging industry. Their corrosion resistance, durability, and ability to maintain sterility make them essential for manufacturing containers, components, machinery, and labeling in the sector.

- Q: Can stainless steel strips be polished?

- Yes, stainless steel strips can be polished. Stainless steel is a versatile material that can be polished to achieve a variety of finishes, ranging from a reflective mirror-like finish to a brushed or satin finish. Polishing stainless steel strips can be done using various methods, such as mechanical polishing, electrochemical polishing, or chemical polishing. The choice of method depends on the desired outcome and the specific requirements of the application. Polishing stainless steel strips not only enhances their aesthetic appeal but also helps to improve their corrosion resistance and cleanability.

- Q: Are stainless steel strips suitable for architectural applications?

- Yes, stainless steel strips are suitable for architectural applications. Stainless steel is a versatile and durable material that is widely used in the architectural industry for various applications. It offers excellent corrosion resistance, high strength, and an attractive appearance, making it a popular choice for both interior and exterior architectural elements. Stainless steel strips can be used in a wide range of architectural applications, including wall cladding, roofing, facades, handrails, balustrades, columns, and decorative features. They can be easily shaped, bent, and welded to create customized designs, allowing architects and designers to achieve their desired aesthetics. In addition to its aesthetic appeal, stainless steel is a low-maintenance material that is resistant to staining, scratches, and fading. It is also highly durable and can withstand harsh weather conditions, making it suitable for both indoor and outdoor applications. Furthermore, stainless steel strips are available in various finishes, including brushed, polished, and patterned, providing architects and designers with a wide range of options to choose from. This versatility allows for the integration of stainless steel strips into different architectural styles and designs. Overall, stainless steel strips are an excellent choice for architectural applications due to their durability, corrosion resistance, aesthetic appeal, and ease of customization.

- Q: What are the common uses of stainless steel strips in the aerospace industry?

- Due to their exceptional properties and characteristics, stainless steel strips find numerous applications in the aerospace industry. Fabricating aircraft components is one of their primary uses. These strips are crucial in producing structural parts like wing spars, fuselage frames, and landing gear components. The outstanding strength and corrosion resistance of stainless steel make it the perfect material for these critical components. It guarantees the aircraft's structural integrity and longevity. Aerospace manufacturers often prefer stainless steel strips over other materials due to their ability to endure extreme temperatures and pressures encountered during flight. Another significant application of stainless steel strips in the aerospace industry involves exhaust systems. These strips are essential in constructing exhaust pipes, mufflers, and heat shields. Thanks to stainless steel's heat resistance properties, it can withstand the high temperatures generated by aircraft engines while maintaining its structural integrity. Furthermore, stainless steel strips are employed in fabricating fuel tanks and hydraulic systems for aircraft. The corrosion resistance of stainless steel guarantees the protection and longevity of these vital components, preventing leaks and failures. Moreover, stainless steel strips are utilized in aerospace fastener manufacturing. They are instrumental in creating a range of screws, bolts, and rivets that hold aircraft components together. The high tensile strength and durability of stainless steel make it the ideal material for these fasteners, ensuring the aircraft's structural stability and safety. In conclusion, stainless steel strips play a crucial role in the aerospace industry due to their outstanding properties. They are widely used in fabricating structural components, exhaust systems, fuel tanks, hydraulic systems, and fasteners. The high strength, corrosion resistance, and heat resistance of stainless steel make it an indispensable material for guaranteeing the safety, reliability, and performance of aircraft.

- Q: Can stainless steel strips be used in architectural applications?

- Yes, stainless steel strips can be used in architectural applications. Stainless steel is highly durable, corrosion-resistant, and can be easily formed into various shapes and sizes. It is commonly used in architectural designs for cladding, roofing, handrails, and decorative elements due to its aesthetic appeal and long-lasting performance.

- Q: Can stainless steel strips be used in textile machinery?

- Yes, stainless steel strips can be used in textile machinery. They are frequently used in various components of textile machinery such as guide rails, blades, and frames due to their durability, corrosion resistance, and high strength properties.

Send your message to us

Stainless Steel Coil 304 Surface No.1 Hot Rolled Coil

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords