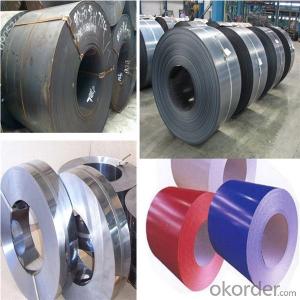

Stainless Steel Coil 201, 202,301, 304, 316,304L,316L,309,410,430

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | 300 Series | Standard: | JIS,AISI,GB | Length: | as customers' requested |

| Thickness: | 0.1-120mm | Width: | 1000-2000mm | Place of Origin: | Shanxi China (Mainland) |

| Brand Name: | CNBM | Model Number: | 309S | Type: | Coil |

| Application: | petroleum refining | Certification: | SGS, ISO | Color: | natural color |

| Packing: | Standard export seaworthy packing or according to your requirements | Available Finish: | 2B/BA/8K/No.4/SB/HL | Edge: | slit edge and mill edge |

| Features: | accurate dimensions | Manufacture technology: | cold drawn,pickling, hot rolled and cold rolled | Quality: | high quality 201, 304,316,304L,316L,309,410,430 Stainless Steel Coil |

| Stock: | Always in stock | Item: | 201, 202,301, 304,316,304L,316L,309,410,430 Stainless Steel Coil |

Packaging & Delivery

| Packaging Detail: | Standard export packing or as customer's requirement ASTM 309S Stainless Steel Coil |

| Delivery Detail: | In 15 days |

Specifications

201, 202,301, 304,316,304L,316L,309,410,430 Stainless Steel Coil

Width:1000-2000mm

Thickness: 0.1-120mm

Quality:High quality

Product Description

ASTM 309S Stainless Steel Coil

Thickness:0.1-120mm

Width:1000-2000mm

Length: As required

Typical physical properties for stainless steel coil

Grade | Chemical composition | ||||||

C | Si | Mn | P | S | Ni | Cr | |

% | % | % | % | % | % | % | |

309S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.04 | ≤0.030 | 12.00-15.00 | 22.00-24.00 |

Item | 201, 202,301, 304,316,304L,316L,309,410,430 Stainless Steel Coil |

Technical | Hot rolled and cold rolled |

Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,GB/T3280-2007,EN10095-99,JIS4312,etc |

Material | 201, 202,301, 304,316,304L,316L,309,410,430 |

Surface | NO.1,2B, mirror finish,4K,8K,Hairline finish |

Thickness | 0.1-120mm |

Width | 1000-2000mm |

Price term | FOB,CFR,CIF,CNF |

Application | Stainless steel coil applies to construction field, ships building industry, petroleum, chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Stainless steel coil can be made according to the customer’s requirements. |

Contact | If you have any question, please feel free to contact me. |

- Q: Consider a steel rod of diameter 4.5 mm and length 3.3 m. If a compressive force of 4900 N is applied to each end, what is the change in the length of the rod?

- You need to calculate the stress on the rod and compare this with the mechanical properties of the steel. It would help if you were given more info. You will need to know something about the steel such as the yeild stress and E, the modulus of elasticity. The value of E is about the same for a wide range of steels. So long as the applied stress is below the yield stress, the strain is all elastic and is calculated from E. The real answer is that you can not answer this question since you do not know what the temperature is. Given the applied load, the change in length will be much different at room temperature than at 1500C.

- Q: What is the typical lead time for ordering steel coils?

- The typical lead time for ordering steel coils can vary depending on factors such as the supplier, quantity required, and current market conditions. However, it is common for lead times to range from a few weeks to several months.

- Q: How are steel coils inspected for coil set?

- Steel coils are inspected for coil set by uncoiling a portion of the coil and measuring the amount of curvature or shape deviation. This is done using specialized equipment and techniques to accurately assess and quantify the coil set present in the steel coils.

- Q: What are the different coil leveling line configurations used for steel coils?

- There are several different coil leveling line configurations used for steel coils, each designed to meet specific requirements and preferences in the steel industry. Some of the commonly used coil leveling line configurations include: 1. Straightener - This configuration consists of a straightening machine that is used to remove any coil shape defects or distortion. It typically features a series of rollers that apply pressure to the coil, gradually straightening it out. 2. Leveler - A leveler configuration is used to flatten the coil, ensuring a consistent thickness throughout. This configuration typically utilizes a series of rollers that apply pressure to the coil, flattening it out to the desired thickness. 3. Combination Straightener/Leveler - This configuration combines the functions of straightening and leveling into a single machine. It features a combination of rollers and straightening elements, allowing for both shape correction and thickness leveling in a single pass. 4. Looping Pit - In this configuration, the coil is fed into a looping pit, which allows for the accumulation of coils to be processed continuously. The looping pit provides a buffer between the entry and exit sections of the leveling line, enabling continuous operation and accommodating variations in coil supply and demand. 5. Tension Leveler - A tension leveler configuration applies tension to the coil during the leveling process. This tension helps to remove shape defects and ensures a flat, uniform surface. 6. Rotary Shear - This configuration incorporates a rotary shear that cuts the coil to the desired length after it has been leveled. The rotary shear is typically synchronized with the speed of the leveling line to ensure accurate and precise cutting. These are just a few examples of the different coil leveling line configurations used for steel coils. The choice of configuration depends on various factors such as the desired final product specifications, coil dimensions, processing speed requirements, and budget considerations.

- Q: What are the different types of steel alloys used in coil production?

- There are several types of steel alloys used in coil production, including carbon steel, stainless steel, and high-strength low-alloy (HSLA) steel. These alloys offer varying levels of strength, corrosion resistance, and formability, making them suitable for different applications in industries such as automotive, construction, and manufacturing.

- Q: How does the steel coil market vary regionally?

- The steel coil market is subject to regional variations due to a variety of factors, including the level of industrialization, economic development, and the particular demands and requirements of each region. In well-developed regions such as North America and Europe, the steel coil market is quite mature and highly competitive. These regions have established manufacturing industries and infrastructure, resulting in a strong demand for steel coils across various sectors like automotive, construction, and machinery. Technological advancements, product innovation, and the need for high-quality materials drive the market in these areas. On the other hand, developing regions like Asia-Pacific, Latin America, and the Middle East & Africa are experiencing rapid industrialization and urbanization, leading to an increased demand for steel coils. These regions have growing construction sectors, thriving automotive industries, and a rise in infrastructure projects, all contributing to the growing need for steel coils. Moreover, the availability of cheap labor and raw materials in some of these regions makes them attractive for steel coil production. Additionally, regional variations in regulations and trade policies also impact the steel coil market. Tariffs, import/export restrictions, and government initiatives promoting domestic production can affect market dynamics. For example, protectionist measures like trade barriers or anti-dumping policies can restrict the import of steel coils, leading to increased domestic production and regional market growth. Geographical factors and climate conditions also play a role in influencing regional steel coil markets. Coastal regions with high humidity levels and exposure to saltwater require corrosion-resistant steel coils, while inland regions with extreme temperatures may demand coils with specific mechanical properties to withstand such conditions. Overall, the steel coil market varies from region to region due to differences in industrialization, economic factors, specific demands, regulations, and geographical considerations. It is essential for steel coil manufacturers, suppliers, and consumers to understand these variations in order to effectively navigate the market and take advantage of the opportunities that exist in each region.

- Q: what are the characteristics when of iron or steel when stretched? which one could be stretched further? which one stretches more evenly?thankyou

- Technically, this is known as ductility. a material which can be permanently bent and stretched is said to be ductile. Pure iron, when it lacks carbon and impurities like sulfur and phosphorus, is relatively soft, ductile, and weak. It's about as soft as brass. It can be stretched to about 50% of it's original length before it breaks. The amount a sample can be stretched without breaking is known as elongation. The key to steel is the addition of about 2 parts per thousand of carbon, or around 0.2%. This alters the crystal structure and makes steel much harder, stronger, and tougher, though it also becomes somewhat less ductile. Mild steel, with a low carbon content, has an elongation of around 30% Adding more carbon makes the steel yet stronger, but further reduces the elongation. Adding more than 2-3% carbon produces what is known as Cast Iron. Cast iron is brittle. It has virtually no ductility. It's pretty cheap to produce though.

- Q: How are steel coils transported internationally?

- Steel coils are typically transported internationally by sea, as they are usually too heavy and bulky to be transported by air. The most common method of transportation is by using specialized shipping containers known as flatracks or open-top containers. These containers allow for easy loading and unloading of the steel coils onto the vessel. Before transportation, the steel coils are usually securely strapped or banded together to prevent any movement or damage during transit. They are then loaded onto the flatracks or open-top containers using cranes or forklifts. The coils are carefully placed and secured onto the containers to ensure stability and to prevent shifting during the journey. Once loaded, the containers are sealed and transported to the nearest port, where they are loaded onto cargo ships. These ships are specifically designed to transport heavy and oversized cargo. They are equipped with specialized handling equipment such as cranes and ramps to facilitate the loading and unloading of the containers. During the journey, the cargo ships follow predetermined shipping routes to reach the destination port. The duration of the journey depends on the distance between the origin and destination ports. Steel coils are typically transported in large quantities, so multiple containers may be loaded onto a single ship. Upon arrival at the destination port, the containers are unloaded from the cargo ship using cranes or ramps. The steel coils are then carefully removed from the containers and transported to their final destination, which may involve further transportation by road or rail. Throughout the transportation process, it is crucial to ensure that the steel coils are adequately protected from moisture, corrosion, and other potential damages. Special attention is paid to the handling and stowage of the coils to minimize the risk of any structural damage or deformation. In summary, steel coils are transported internationally by sea using specialized shipping containers. The coils are securely loaded onto flatracks or open-top containers, which are then transported by cargo ships to the destination port. Proper handling and stowage techniques are employed to ensure the safe and secure transportation of the steel coils.

- Q: What's the best way to clean granite countertops and stainless steel appliances? My countertops especially always look dull and streaky. Thanks!!!!!!!

- Stainless steel kitchen appliances look best when they're clean and shiny. To clean tough stains and cooking grease, and give them a dazzling shine, try the same detergent you would use when washing the dishes. One formulated to cut grease works especially well.This also works well for general kitchen cleaning.Waterless hand soap also works great as a polish, simply rub on, and polish - no rinsing. :) Don't use an ordinary kitchen cleaning product to clean granite. The newest technology uses peroxide and detergents to penetrate soiled areas. Simply spray a product such as Bio-OX Citrus Concentrate on the soiled area, allow it to penetrate for a few minutes, then wipe clean. Baking soda can be sprinkled on for a more abrasive cleaning action. Repeat if necessary. Granite can also be cleaned using warm, sudsy water (a mild detergent such as a grease cutting dish detergent or laundry detergent is fine) or a solution of borax and water. Thoroughly rinse and buff dry. To remove stains from granite, make a paste of baking soda and hydrogen peroxide or baking soda and Bio-OX Citrus Concentrate and cover the stain with the paste. Cover the paste with a damp cloth, leave overnight, then wet down and scrub with a nonmetallic scrubbing pad. Rinse thoroughly with clean water. Wipe up any spills as they happen so they don't soak in, and always dry coutertops after washing the dishes.

- Q: How are steel coils used in the production of agricultural fencing?

- Steel coils are used in the production of agricultural fencing by being processed and shaped into wire strands that are then woven or welded to create the fence panels. These coils provide the necessary strength, durability, and rigidity required for effective and long-lasting agricultural fencing solutions.

Send your message to us

Stainless Steel Coil 201, 202,301, 304, 316,304L,316L,309,410,430

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords