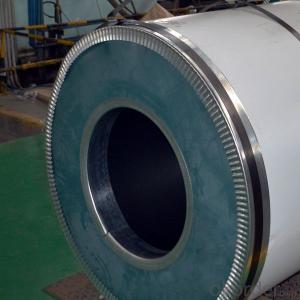

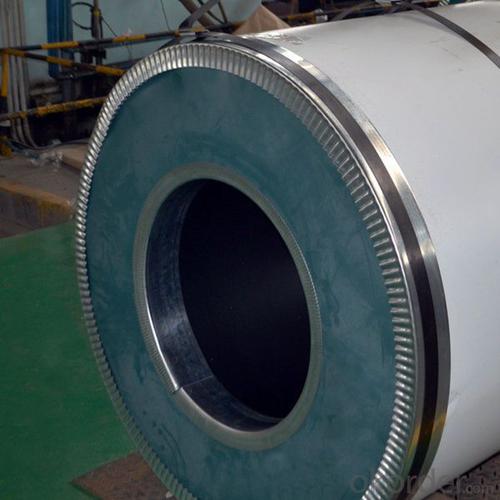

Stainless Good No.1 Finish Quality Steel Coils NO.1 Finish Steel Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Type | Stainless Steel Coil /Cold rolled Steel Coils |

Thinckness | 0.23mm-0.8mm |

Diameter | 115mm-560mm |

Quantity | as customer's requirement |

Finish | 2B,BA,HL,MIRROR,NO.1-NO.4,8K,and so on. |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Material | 201,202, 301,304,410,430,409 |

Application range | Foodstuff, Gas, metallurgy, biology, electron, chemical, petroleum, boiler, nuclear energy, Medical equipment, fertilizer etc |

Package | Standard export sea-worthy packing |

Delivery time | 7-15 days |

Quality | Primary |

Productivity | 3000-4000 tons/month |

Note | We can produce other standard as the customers’ requirement |

Detail picture for Stainless Steel Coils/Sheets

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Application for Stainless Steel Coils/Sheets

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ for Stainless Steel Coils/Sheets:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

FAQ for Stainless Steel Coils/Sheets:

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q: Are stainless steel sheets available in different finishes?

- Yes, stainless steel sheets are available in different finishes.

- Q: What are the different types of surface treatments for stainless steel sheets?

- There are several types of surface treatments for stainless steel sheets, including brushing, grinding, polishing, and coating. Brushing creates a textured finish, grinding removes imperfections, polishing enhances shine, and coating adds a layer of protection.

- Q: Are stainless steel sheets resistant to UV radiation?

- Generally, stainless steel sheets have resistance to UV radiation. The composition of stainless steel consists mainly of iron, chromium, and other alloying elements, which contribute to its exceptional resistance to various types of corrosion, including UV radiation. The presence of chromium in stainless steel leads to the formation of a protective oxide layer on the surface, acting as a shield against UV rays and preventing oxidation or deterioration of the metal. Nevertheless, it is worth noting that continuous exposure to intense UV radiation can still result in some discoloration or fading of the stainless steel surface over time. To preserve the appearance and durability of stainless steel sheets used outdoors, it is advisable to regularly clean and apply appropriate treatments to protect the surface and ensure long-lasting performance.

- Q: What are the benefits of using embossed stainless steel sheets in elevator doors?

- There are several benefits of using embossed stainless steel sheets in elevator doors. Firstly, the embossed pattern adds a visually appealing and aesthetic element to the elevator doors, enhancing the overall appearance of the elevator interior. This can create a more luxurious and sophisticated atmosphere for passengers. Secondly, embossed stainless steel sheets are highly durable and resistant to scratches, dents, and corrosion. Elevator doors are subjected to constant use and can be easily damaged, but the use of embossed stainless steel sheets ensures that the doors maintain their pristine condition for a longer period of time. This durability also reduces maintenance and replacement costs over the lifespan of the elevator. Additionally, embossed stainless steel sheets provide a high level of hygiene. Stainless steel is inherently resistant to bacteria and germs, making it an ideal material for elevator doors. The embossed pattern further aids in hiding fingerprints and smudges, ensuring that the doors remain clean and sanitary with minimal maintenance. Moreover, embossed stainless steel sheets offer excellent fire resistance properties. Elevators are enclosed spaces, and in the unfortunate event of a fire, the use of embossed stainless steel sheets in the doors can help contain the flames and prevent the spread of fire, providing an added level of safety for passengers. Lastly, embossed stainless steel sheets are easy to clean and maintain. With a smooth surface and resistance to stains and dirt, these sheets can be easily wiped down with a mild cleaner, keeping the elevator doors looking pristine and reducing the amount of time and effort required for cleaning. In summary, the benefits of using embossed stainless steel sheets in elevator doors include enhanced aesthetics, durability, hygiene, fire resistance, and ease of maintenance. These advantages make embossed stainless steel sheets a popular choice for elevator manufacturers and building owners alike.

- Q: What are the standard sizes and thicknesses of stainless steel sheets?

- Stainless steel sheets are utilized in numerous industries and applications due to their wide range of standard sizes and thicknesses. Typically, the standard sizes vary from 4 feet by 8 feet to 5 feet by 10 feet, but customized sizes can also be obtained based on specific needs. In terms of thickness, stainless steel sheets are offered in various standard options. These include 20 gauge (0.036 inches), 18 gauge (0.048 inches), 16 gauge (0.060 inches), 14 gauge (0.075 inches), 12 gauge (0.105 inches), and 10 gauge (0.135 inches). It is important to note that these thicknesses indicate the nominal thickness, and the actual thickness may have slight variations. Additionally, it is worth noting that stainless steel sheets are also available in metric sizes. Common thicknesses in metric sizes range from 0.5 mm to 3 mm. This provides flexibility and compatibility with international standards and specifications. In summary, the standard sizes and thicknesses of stainless steel sheets are determined by industry standards and customer requirements. This ensures their widespread availability and versatility for various applications such as construction, automotive, aerospace, and kitchen equipment manufacturing, among others.

- Q: Can stainless steel sheets be used for outdoor signage?

- Yes, stainless steel sheets can be used for outdoor signage. Stainless steel is a durable and corrosion-resistant material that can withstand harsh weather conditions and maintain its appearance over time. It is commonly used in outdoor signage due to its ability to resist rust, fading, and damage from exposure to sunlight, rain, snow, and other environmental elements. Additionally, stainless steel sheets can be customized with various finishes, such as brushed or polished, to enhance their visual appeal and make them suitable for any outdoor signage application.

- Q: How do you prevent staining on stainless steel sheets?

- To avoid staining stainless steel sheets, there are several actions you can take: 1. Regularly clean the sheets using mild soap or detergent and warm water. Harsh chemicals and abrasive cleaners should be avoided as they can harm the surface. 2. Keep the sheets away from corrosive substances such as bleach, ammonia, and acidic cleaners. If spills occur, quickly rinse the affected area with water and thoroughly dry it. 3. Apply a protective coating or film to create a barrier between the surface and potential staining agents. There are various products designed specifically for stainless steel that can be used, such as protective sprays or polishes. 4. Properly maintain the sheets by regularly inspecting for any damage, scratches, or rust. Address any issues promptly by cleaning or repairing the affected areas to prevent staining. 5. Use soft cloths or non-abrasive sponges when cleaning or maintaining the sheets to avoid scratching the surface. Avoid using steel wool or abrasive materials that can cause marks or damage. 6. Ensure the sheets are thoroughly dried after cleaning to prevent water spots or mineral deposits. Use a clean, lint-free cloth to remove any moisture. 7. Handle the sheets with care to prevent scratching or damaging the surface. Avoid dragging or sliding heavy objects across them, as this can leave marks or cause abrasions. By following these preventive measures, you can maintain the appearance and integrity of stainless steel sheets and minimize the risk of staining.

- Q: What does stainless steel plate mean?

- The corrosion resistance of stainless steel mainly depends on its alloy composition (chromium, nickel, titanium, silicon, aluminum, manganese, etc.) and the internal structure of the alloy, and the main role is chromium. Chromium has high chemical stability, can form a passive film on the steel surface, so that the metal is isolated from the outside, protect the steel plate from oxidation and increase the corrosion resistance of the steel plate. When the passive film is destroyed, the corrosion resistance will decrease.

- Q: Are stainless steel sheets suitable for laboratory equipment or instruments?

- Laboratory equipment and instruments benefit greatly from the use of stainless steel sheets. Their high suitability stems from stainless steel's exceptional resistance to corrosion, a critical feature in laboratory settings where exposure to various chemicals and substances occurs. Moreover, stainless steel exhibits remarkable heat resistance, rendering it fitting for applications involving high temperatures or sterilization procedures. Furthermore, stainless steel's ease of cleaning and maintenance plays a vital role in preserving a sterile and hygienic laboratory environment. The durability and strength of stainless steel contribute to its ability to withstand heavy usage and ensure long-lasting performance. Consequently, stainless steel sheets have gained a reputation as a dependable and widely preferred choice for laboratory equipment and instruments due to their corrosion resistance, heat resistance, cleanliness, and durability.

- Q: What's the difference between 201 and 204 stainless steel plates? Thank you

- The price is different: 01 cheaper, 04 expensive. Toughness is different: 01 hardness, 04 toughness.

Send your message to us

Stainless Good No.1 Finish Quality Steel Coils NO.1 Finish Steel Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords