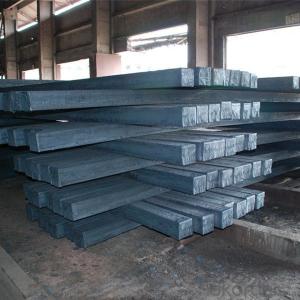

Square Steel Billet, Square Bar, Mild Steel Billet Chinese Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Square steel billet, square bar, mild steel billet best price from China manufacturer

| Name: | Square bar |

| LENGTH: | 6 meter to 12 meter (+ 50mm) |

| Size: | 100*100, 120*120, 150*150, 200*200 |

| Grade: | 3SP,5SP,Q235,20MnSi. |

| Shape: | Square, Round |

| Technique: | Hot-Rolled |

| Standard: | ASTM/GB |

| BENDING | No more than 5mm in 1 meter No more than 30mm in 6 meter No more than 60mm in 12 meter |

| ANGULAR TWIST | No more than 1 degree per meter and not more than 6 degree over 12 meter length. |

| Chemical composition | C, Si, Mn, P, S, N, etc |

Product Description

Chemical Properties

| Size | 60*60/90*90/100*100/120*120/150*150 |

| Length | 6000mm-12000mm |

| Standard | GB |

| Application | To produce bars or other applications |

| Grade | Q195/Q235/Q275/3SP/5SP/20MnSi |

| Packing terms | TT/LC |

| Package | Mill's standard packing or as client's requirement |

| Delivery time | Within 10-30 days after receiving the deposit or LC |

Chemical Composition

| Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

| Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

| Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

| Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

| 20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

| 3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

| 5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Company Main Product Introduction:

Steel billet

Steel Profile:H-Beam/I-Beam/Equal Angle/Unequal Angle/U Channel /Flat Bar

Steel Plate:Hot Rolled Coil/Hot Rolled Checkered Coil/Cold Rolled Coil/Cutting Sheet

Wire Bar: Round Bar /Wire Rod/Deformed Bar

Steel Pipes: Seamless Pipe, Square/Round Pipes

Galvanized Steel: Angle/Channel/I-Beam/Round Bar/Flat Bar/Round-Square Pipe

Application:

Wire rod, deformed bars, rebar, profile steel, mechine parts and so on

- Q: How are steel coils used in the manufacturing of household goods?

- Household goods rely on steel coils for their manufacturing, utilizing them in various ways. One notable application is in the creation of appliances like refrigerators, washing machines, and ovens. These coils are skillfully molded and formed into different parts and components, fortifying the final product with durability and robustness. Moreover, furniture manufacturing frequently incorporates steel coils, specifically in constructing metal frames for chairs, tables, and bed frames. The coils can be bent, welded, or molded to desired specifications, providing a solid and dependable foundation for these essential household items. Additionally, steel coils find utility in the production of kitchen utensils and cookware. These coils can be expertly stamped or pressed into diverse shapes, including pots, pans, and cutlery. Consequently, this process generates long-lasting and heat-resistant products that are indispensable for everyday cooking and food preparation. In essence, steel coils assume a critical role in the manufacturing of household goods, imparting strength, durability, and adaptability to a wide array of products.

- Q: How are steel coils inspected for surface cleanliness after processing?

- Steel coils are inspected for surface cleanliness after processing through visual examination, using techniques such as optical scanning or high-resolution cameras. Additionally, other methods like acid etching or solvent cleaning may be employed to remove any contaminants or residues on the surface to ensure the coils meet the required cleanliness standards.

- Q: I received a very nice set of stainless steel cookware as a wedding gift. While very pretty, Im finding them almost useless for cooking. Everything sticks, they're difficult to clean, and Im using my old non-stick pans instead. Should I simply leave the stainless out for decortive purposes, or are stainless steel pans better for some applications?

- Stainless steel has some benefits: 1) Dishwasher safe: my anodized aluminum pots are NOT dishwasher safe (my wife put one in and it lost its gun-metal gray finish - sad) 2) Conductivity: most stainless steel cookware has an aluminum (or copper) middle - this transfers the heat nicely - steel by itself does not conduct heat evenly. All Clad cookware refers to the fact that the aluminum within the cookware is clad in steel. 3) Aesthetics: stainless is pretty. Stainless is not anti-stick, so you'll have to use all your skills to avoid sticking. 1) Use oil or butter: heat your pan before oiling. Once to temp, add the oil/butter and wait for it to heat-through. THEN add your food - sticking should be minimized. 2) Move your food around a lot: once you add a piece of food that is likely to stick, move it shortly afterward. This will prevent the food from gluing itself to one spot in the pan - a crust will start to appear, and that will protect the food from sticking. 3) Love the fond: anti-stick pans don't have a good chance at fond development (fond is the stuff that sticks to the bottom of the pan, and is crucial to pan sauce creation). You should experiment with your cookware, or send it to me: I am wishing for some new cookware.

- Q: Looking for an insight here into what hiking with steel toe-capped boots would be like, as I saw a nice pair of steel toed magnums that I plan to use for my future hiking (which I will be doing a fair amount of in the future). They seemed fairly comfortable, but I am curious into what others have to say and what might be known of this sort of approach. Thanks in advance.

- Steel toed boots are very heavy compared to hiking boots, after a long hike (especially in rough terrain) the extra weight is gonna tire you out. Steel toes are made for things like construction, or doing a task where extra protection of the toe is needed. So it's not ideal, but whatever floats your boat man (better than wearing tennis shoes). I personally have Converse composite toed boots from my airsofting days and since im too cheap to buy dedicated hike boots, I use it for hiking. Its supposedly made for military use and is much lighter than steel toe. But WAIT!!! lets say you dont have a gun or knife and you run into a pissed off Sasquatch, a steel toe boot too the nutz would do well in puttin the hurt on the dude.

- Q: How are steel coils used in the production of roofing materials?

- Steel coils are used in the production of roofing materials by being fed into a roll-forming machine, which shapes the coils into the desired profile for the roofing panel. The coils are then cut to the appropriate length, coated with protective finishes, and formed into individual roofing panels that are ready to be installed on buildings.

- Q: How would you calculate the maximum plastic deformation (expansion) a steel pipe can handle before it actually fails?

- You can calculate the maximum reversible strain, for elastic loading as follows: You need to look up the yield strength (for that particular type of steel). Divide this yield strength by the elastic modulus of steel (also called Young's modulus). That gives you the strain at the onset of yielding, the maximum you can strain the steel fibers before crossing the point of no return. If you are interested in the strain until failure, you need to take tensile test measurements. Seldom do people document an equation to model the non-elastic portion of the stress-strain curve of the specimen, because seldom do we design systems to operate with materials which yield. We want systems which only deform reversibly and elastically. This means you need to perform an experiment to find what you are actually desiring to know.

- Q: What are common uses for steel coils?

- Steel coils are commonly used in various industries for purposes such as manufacturing automobiles, appliances, construction materials, and metal fabrication. They are also used in the production of pipes, tubes, and structural components, making them a versatile material for a wide range of applications.

- Q: Some stainless steel products are as shiny as chrome. Can all/most stainless steel be polished to a chrome like luster.

- depends on the amount on nickel used in the manufacturing but mostly yes

- Q: Is there any way to melt steel without the intense heat of a blast furnace?

- How To Melt Steel

- Q: How are steel coils used in the production of structural steel?

- Steel coils are used in the production of structural steel by being unwound and processed through various manufacturing techniques, such as rolling and shaping, to create different structural components like beams, columns, and plates.

Send your message to us

Square Steel Billet, Square Bar, Mild Steel Billet Chinese Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords