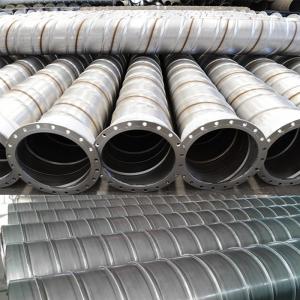

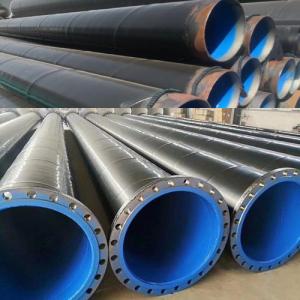

Underground Epoxy Coated Spiral Welded Corrugated Composite Steel Pipe for Mining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Underground Epoxy Coated Spiral Welded Corrugated Composite Steel Pipe for Mining

Press grade: Maximum PN -0.097MPa

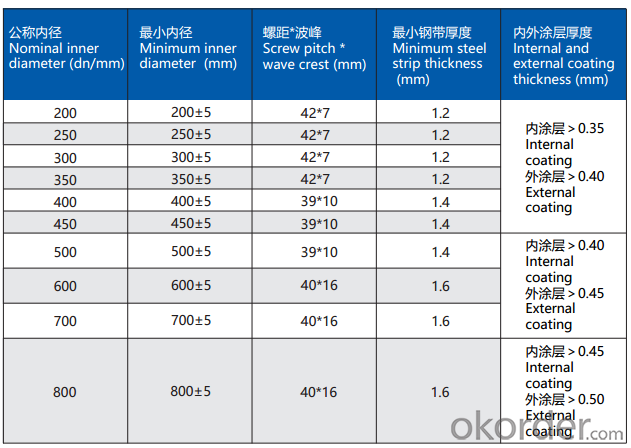

Size: DN200MM-DN800MM

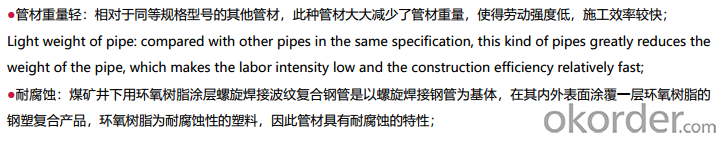

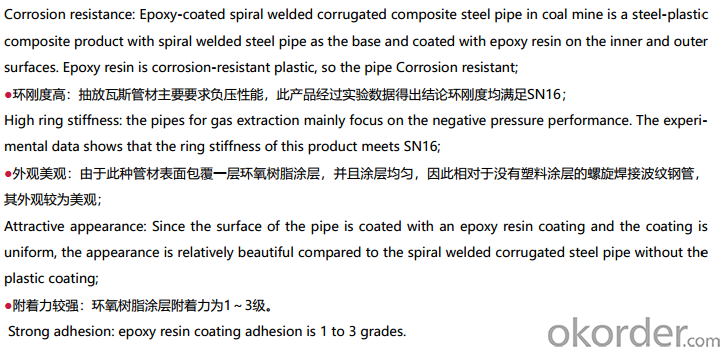

Features:

Specification

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q: How are steel pipes protected against galvanic corrosion?

- Steel pipes are protected against galvanic corrosion through various methods including the application of protective coatings such as zinc or epoxy, cathodic protection systems, and the use of corrosion inhibitors.

- Q: How do steel pipes handle water erosion?

- Steel pipes handle water erosion well due to their inherent strength and durability. The smooth surface of steel pipes helps to minimize friction and reduce the potential for erosion. Additionally, the corrosion-resistant nature of steel prevents rusting, ensuring long-term protection against water erosion.

- Q: How are steel pipes used in the construction of industrial facilities?

- Steel pipes are commonly used in the construction of industrial facilities for various purposes such as transporting fluids, gases, and steam, as well as providing structural support and carrying electrical wiring. They are durable, resistant to corrosion, and can withstand high pressure and temperature, making them ideal for industrial settings.

- Q: What is the electrical conductivity of steel pipes?

- The electrical conductivity of steel pipes is relatively low, as steel is a poor conductor of electricity.

- Q: Can steel pipes be used for underground cable protection?

- Yes, steel pipes can be used for underground cable protection. Steel pipes offer durability, strength, and resistance to corrosion, making them suitable for protecting cables from external elements and potential damage. Additionally, steel pipes can provide a secure and reliable conduit for underground cables, ensuring their safety and longevity.

- Q: Can steel pipes be used for hydropower generation?

- Yes, steel pipes can be used for hydropower generation. Steel pipes are often used in the construction of hydroelectric power plants to transport water from a higher elevation to lower areas, where the water's kinetic energy is converted into mechanical energy to generate electricity. The durability and strength of steel pipes make them suitable for this purpose, as they can withstand the high pressure and flow rates of water in hydropower systems.

- Q: Are steel pipes suitable for underground installations in areas with high moisture content?

- In areas with high moisture content, steel pipes are commonly used for underground installations. However, it is important to consider certain factors when utilizing steel pipes in such conditions. Prolonged exposure to moisture can lead to corrosion, which is a significant concern. To mitigate this risk, it is crucial to employ steel pipes that are specifically designed for underground installations and are coated with protective materials like epoxy or polyethylene. These protective coatings act as a barrier between the steel and the surrounding moisture, preventing corrosion and prolonging the lifespan of the pipes. Furthermore, proper installation techniques, including sufficient pipe bedding and backfilling, must be adhered to in order to ensure that the pipes are adequately supported and shielded from external forces. Regular inspection and maintenance are also advisable to promptly identify any signs of corrosion or damage and address them accordingly. Overall, by taking the appropriate precautions and conducting regular maintenance, steel pipes can be a viable choice for underground installations in areas with high moisture content.

- Q: How do you calculate the flow velocity in a steel pipe?

- The flow velocity in a steel pipe can be calculated using the equation: velocity = (flow rate) / (cross-sectional area of the pipe).

- Q: How are steel pipes used in the manufacturing of fire sprinkler systems?

- Steel pipes are commonly used in the manufacturing of fire sprinkler systems due to their durability, strength, and resistance to high temperatures. These pipes are used to transport pressurized water or fire retardant throughout the sprinkler system, ensuring quick and effective fire suppression. The steel pipes are installed strategically throughout the building, delivering water to sprinkler heads that are activated when heat is detected. Overall, steel pipes play a crucial role in the safe and efficient operation of fire sprinkler systems, protecting lives and property from the devastating effects of fires.

- Q: How are steel pipes protected against fire?

- Steel pipes are typically protected against fire through the application of fire-resistant coatings or by encasing them in fire-rated materials, such as concrete or gypsum board. Additionally, fire sprinkler systems or fire-resistant insulation may be installed around the pipes to provide an added layer of protection.

Send your message to us

Underground Epoxy Coated Spiral Welded Corrugated Composite Steel Pipe for Mining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords