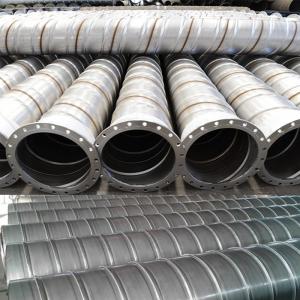

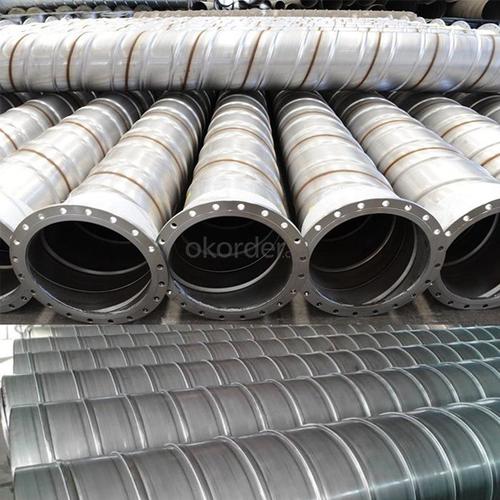

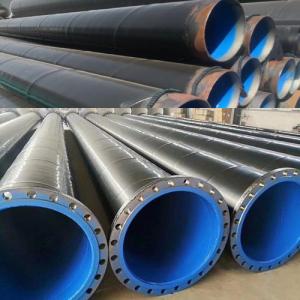

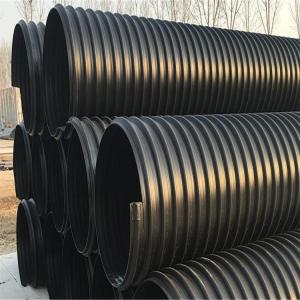

Underground Rib Reinforced Spiral Welded Stainless Steel Pipe for Mining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Underground Rib Reinforced Spiral Welded Stainless Steel Pipe for Mining

Press grade: Maximum PN -0.097MPa

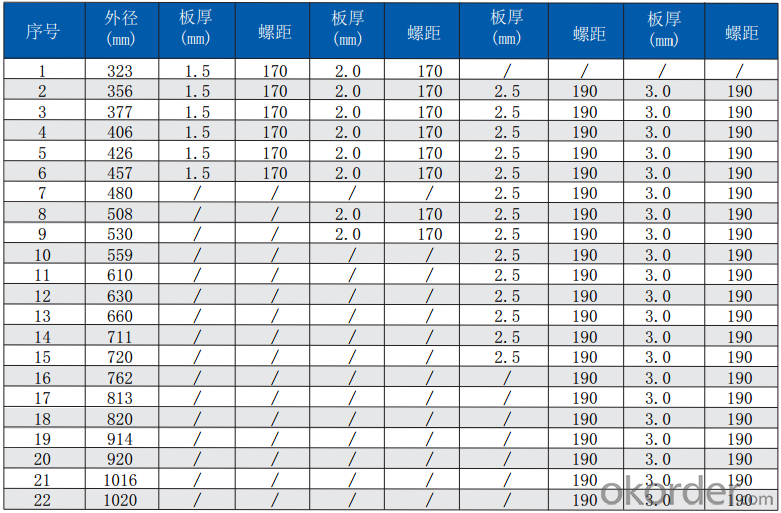

Size: DN300MM-DN1100MM

Standards:

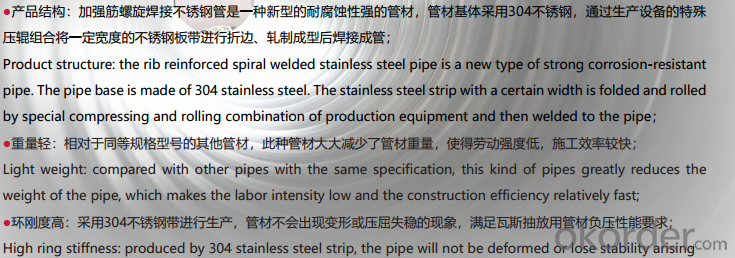

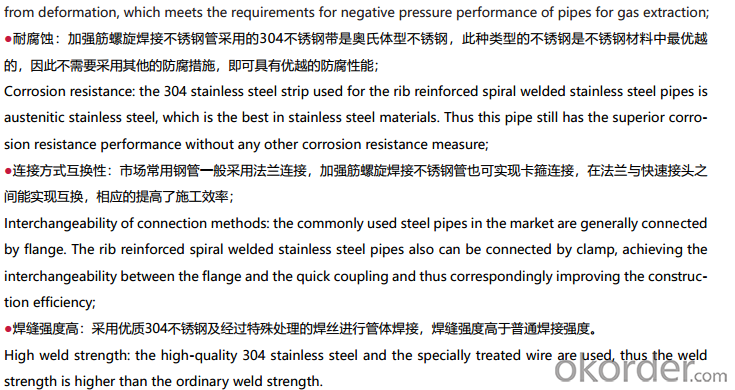

Features:

Specification:

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q: Are steel pipes suitable for use in sewage treatment plants?

- Yes, steel pipes are suitable for use in sewage treatment plants. They are durable, strong, and resistant to corrosion, making them ideal for handling the harsh environment and corrosive substances found in sewage treatment plants. Steel pipes also offer excellent flow characteristics and can withstand high pressure, making them reliable for transporting wastewater and sewage within the facility.

- Q: How are steel pipes used in the manufacturing of offshore wind turbines?

- Steel pipes are used in the manufacturing of offshore wind turbines for various purposes such as supporting the turbine structure, housing electrical cables, and transporting fluids like hydraulic oil and cooling water. These pipes provide structural strength, corrosion resistance, and durability, ensuring the stability and functionality of the turbines in the harsh offshore environment.

- Q: Heating system DN40 and DN32 welded steel pipe how to connect?

- Is the wire: also called pipe thread connection, the malleable steel pipe fittings, malleable iron is the thread connection using DN40X32 diameter hoop.

- Q: Can steel pipes be used for chemical processing plants?

- Yes, steel pipes can be used for chemical processing plants. Steel pipes are commonly used in chemical processing plants due to their strength, durability, and resistance to corrosion, making them suitable for transporting various chemicals and fluids safely and efficiently. Additionally, steel pipes can withstand high temperatures and pressures, which are often encountered in chemical processing operations.

- Q: What are the applications of galvanized steel pipes?

- Galvanized steel pipes have a wide range of applications in various industries. They are commonly used in plumbing systems to deliver water and gas due to their excellent corrosion resistance. Additionally, they are used in the construction industry for structural purposes, such as scaffolding, fences, and handrails. Galvanized steel pipes are also utilized in the agricultural sector for irrigation systems and as posts for supporting crops. Furthermore, they find usage in oil and gas pipelines, HVAC systems, and automotive manufacturing. Overall, the applications of galvanized steel pipes are diverse, making them an essential material in multiple sectors.

- Q: Can steel pipes be used for conveying oil?

- Steel pipes are suitable for the transportation of oil. In the oil and gas industry, steel pipes are widely utilized for the conveyance of oil due to their robustness, longevity, and resistance to corrosion. The exceptional strength of steel pipes enables them to endure the demanding conditions of high pressure and temperature that often accompany oil transportation. Furthermore, steel pipes are less susceptible to leakage and damage in comparison to alternative materials, thus making them a dependable choice for the efficient transfer of oil over extensive distances. Moreover, the sleek interior surface of steel pipes aids in reducing friction and improving the oil flow. Overall, steel pipes are the preferred option for oil transportation owing to their superior mechanical properties and enduring performance.

- Q: Can steel pipes be used for electrical conduit systems?

- No, steel pipes cannot be used for electrical conduit systems as they are conductive and can pose a safety risk. Non-metallic conduits, such as PVC or fiberglass, are commonly used for electrical wiring to ensure insulation and protect against electrical hazards.

- Q: What are the environmental impacts of steel pipe production and disposal?

- The production and disposal of steel pipes have significant environmental impacts. Firstly, the production of steel pipes requires the extraction of raw materials such as iron ore, coal, and limestone. This extraction process leads to habitat destruction, deforestation, and soil erosion. Additionally, mining and processing these materials require a considerable amount of energy, often derived from fossil fuels, contributing to greenhouse gas emissions and air pollution. The manufacturing process itself involves various stages, including melting, casting, rolling, and coating, all of which require substantial energy inputs and emit significant amounts of carbon dioxide and other greenhouse gases. Moreover, the production of steel pipes involves the use of chemicals and additives that can be harmful to the environment if not managed properly. Furthermore, during the disposal of steel pipes, if not recycled or properly managed, they can end up in landfills, contributing to waste accumulation and taking up valuable space. Steel is generally non-biodegradable and can take hundreds of years to decompose. When steel pipes are dumped in landfills, they can release toxic substances and heavy metals, which can contaminate soil and groundwater. However, it is important to note that steel pipes are highly recyclable, and recycling them significantly reduces the environmental impact. Recycling steel pipes helps conserve natural resources, reduces energy consumption, and lowers greenhouse gas emissions. Additionally, using recycled steel in the production of new pipes requires less energy and results in fewer emissions compared to using virgin materials. To minimize the environmental impacts of steel pipe production and disposal, it is crucial to promote sustainable practices throughout the entire lifecycle of the product. This includes reducing energy consumption, utilizing renewable energy sources, implementing proper waste management strategies, and encouraging the recycling and reuse of steel pipes.

- Q: How are steel pipes marked for identification?

- Steel pipes are typically marked for identification using various methods such as color coding, stenciling, engraving, or applying tags with relevant information such as size, grade, manufacturer, and specifications.

- Q: How do steel pipes handle seismic activities?

- Steel pipes are designed to have high ductility and strength, allowing them to handle seismic activities effectively. The flexibility of steel pipes allows them to absorb and distribute the energy generated during an earthquake, minimizing the risk of structural damage and ensuring the safety of the infrastructure. Additionally, steel pipes can be reinforced with various techniques, such as braces or rubber isolators, to further enhance their seismic resistance.

Send your message to us

Underground Rib Reinforced Spiral Welded Stainless Steel Pipe for Mining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords