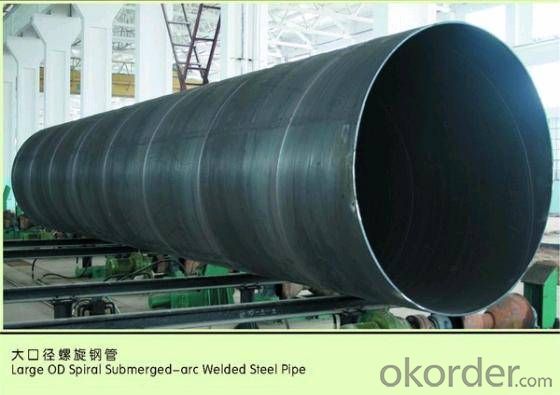

SPIRAL STEEL PIPE 50‘‘ ASTM API LARGE DIAMETER PIPE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation | |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050< span=""> | <0.045< span=""> | <0.030< span=""> | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05< span=""> | <0.045< span=""> | <0.030< span=""> | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045< span=""> | <0.045< span=""> | <0.030< span=""> | >235 | 375-500 | 24-26 |

Q345 | <0.20< span=""> | 1.0-1.6 | <0.040< span=""> | <0.040< span=""> | <0.55< span=""> | >345 | 470-630 | 21-22 |

- Q: How are steel pipes classified based on their schedule?

- Steel pipes are classified based on their schedule, which refers to the thickness of the pipe wall. The schedule classification is denoted by a number, such as 10, 20, 40, 80, etc., with higher numbers indicating thicker walls.

- Q: What's the difference between a cracked carbon steel tube and a liquid carbon steel tube?

- Test: cracking carbon steel pipe in addition to eddy current testing, but also to do ultrasonic testing, and liquid carbon steel tubes are generally only eddy current testing.

- Q: How are steel pipes protected against chemical corrosion?

- Steel pipes are protected against chemical corrosion through various methods such as coating them with corrosion-resistant materials like epoxy or polyethylene. Additionally, cathodic protection techniques like applying sacrificial anodes or using impressed current systems can also be employed to prevent chemical corrosion on steel pipes.

- Q: Can steel pipes be used for underground water supply?

- Yes, steel pipes can be used for underground water supply. However, it is important to consider factors such as corrosion resistance and proper coating to protect the pipes from potential degradation caused by the surrounding soil and water chemistry. Additionally, regular maintenance and inspections are necessary to ensure the longevity and integrity of the steel pipes in underground water supply systems.

- Q: What is the average lifespan of steel pipes?

- The average lifespan of steel pipes varies depending on various factors such as their quality, usage, and maintenance. However, under normal conditions, well-maintained steel pipes can last for several decades or even longer.

- Q: Are steel pipes suitable for use in automotive industries?

- Yes, steel pipes are suitable for use in automotive industries. Steel pipes are highly durable, have excellent strength-to-weight ratio, and can withstand high pressure and temperature conditions, making them ideal for various automotive applications. They are commonly used in exhaust systems, brake lines, fuel lines, and structural components of vehicles due to their reliability and ability to withstand harsh environments.

- Q: What is the role of steel pipes in the transportation of petroleum products?

- Steel pipes have a crucial function in the transportation of petroleum products, as they are specifically designed to endure the high pressure and extreme temperatures associated with oil and gas transportation. A primary responsibility of steel pipes in this process is to serve as a dependable and secure conduit for transporting petroleum products over long distances. They are utilized to construct pipelines that span hundreds or even thousands of miles, connecting oil fields, refineries, and distribution centers. Steel pipes are the preferred choice for this purpose because of their strength, durability, and resistance to corrosion. The high tensile strength of steel allows these pipes to withstand the immense pressure exerted by petroleum products as they flow through the pipelines. Additionally, steel pipes can endure extreme temperatures, ensuring the safe transportation of hot crude oil or refined petroleum products. Moreover, steel pipes possess a high resistance to corrosion, which is of utmost importance given the corrosive nature of petroleum products. To further enhance their corrosion resistance, the pipes are often coated with protective materials such as epoxy or polyethylene. This coating helps prevent leaks or ruptures that could cause environmental damage or safety hazards. Steel pipes also offer cost-effective and efficient transportation of petroleum products. They have a smooth interior surface, which reduces friction and allows for a more efficient flow of oil or gas. This, in turn, helps minimize energy consumption and maximize the throughput of the pipeline system. In conclusion, the main role of steel pipes in the transportation of petroleum products is to provide a reliable, secure, and efficient means of transporting oil and gas over long distances. They are designed to withstand high pressure, extreme temperatures, and corrosion, ensuring the safe and efficient delivery of petroleum products from production sites to refineries and distribution centers.

- Q: What are the environmental impacts of steel pipe production and disposal?

- The production and disposal of steel pipes have significant environmental impacts. Firstly, the production of steel pipes requires the extraction of raw materials such as iron ore, coal, and limestone. This extraction process leads to habitat destruction, deforestation, and soil erosion. Additionally, mining and processing these materials require a considerable amount of energy, often derived from fossil fuels, contributing to greenhouse gas emissions and air pollution. The manufacturing process itself involves various stages, including melting, casting, rolling, and coating, all of which require substantial energy inputs and emit significant amounts of carbon dioxide and other greenhouse gases. Moreover, the production of steel pipes involves the use of chemicals and additives that can be harmful to the environment if not managed properly. Furthermore, during the disposal of steel pipes, if not recycled or properly managed, they can end up in landfills, contributing to waste accumulation and taking up valuable space. Steel is generally non-biodegradable and can take hundreds of years to decompose. When steel pipes are dumped in landfills, they can release toxic substances and heavy metals, which can contaminate soil and groundwater. However, it is important to note that steel pipes are highly recyclable, and recycling them significantly reduces the environmental impact. Recycling steel pipes helps conserve natural resources, reduces energy consumption, and lowers greenhouse gas emissions. Additionally, using recycled steel in the production of new pipes requires less energy and results in fewer emissions compared to using virgin materials. To minimize the environmental impacts of steel pipe production and disposal, it is crucial to promote sustainable practices throughout the entire lifecycle of the product. This includes reducing energy consumption, utilizing renewable energy sources, implementing proper waste management strategies, and encouraging the recycling and reuse of steel pipes.

- Q: Can steel pipes be used for oil transportation?

- Yes, steel pipes are commonly used for oil transportation due to their high strength, durability, and resistance to corrosion.

- Q: What is the difference between black steel pipe and galvanized steel pipe?

- The main difference between black steel pipe and galvanized steel pipe lies in their coating. Black steel pipe is untreated and has a dark, matte appearance, while galvanized steel pipe is coated with a layer of zinc to prevent rusting and has a silver, shiny appearance. This coating makes galvanized steel pipes more durable and suitable for outdoor use, while black steel pipes are commonly used for indoor plumbing and gas lines.

Send your message to us

SPIRAL STEEL PIPE 50‘‘ ASTM API LARGE DIAMETER PIPE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords