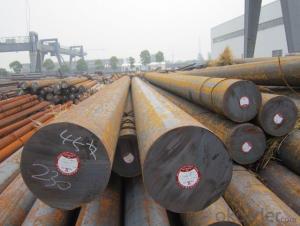

Special Steel 42CrMo Round Bar Steel SCM440

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

| 1.Specification | ||||||||

| Round bar | Diameter(mm) | Length (mm) | ||||||

| 20~600 | 3000~9000 | |||||||

| Plate | Thickness(mm) | Width (mm) | Length (mm) | |||||

| Max:800 | Max:2200 | Max:9000 | ||||||

| *Specification can be customized for sure. | ||||||||

| 2.Chemical Compositons | ||||||||

| Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

| SCM440 | 0.38~0.45 | 0.17~0.37 | 0.50~0.8 | ≤0.035 | ≤0.035 | 0.9~1.2 | 0.15-0.25 | ≤0.3 |

| 4140 | 0.40~0.45 | 0.15~0.35 | 0.75~1.0 | ≤0.035 | ≤0.040 | 0.8~1.1 | 0.15-0.25 | - |

| SCM415 | 0.38~0.43 | 0.15~0.35 | 0.60~0.9 | ≤0.030 | ≤0.030 | 0.9~1.2 | 0.15-0.30 | ≤0.25 |

| 1.7225 | 0.38~0.45 | ≤0.40 | 0.60~0.9 | ≤0.025 | ≤0.035 | 0.9~1.2 | 0.15-0.30 | |

| 3.Delivery Conditions | ||||||||

| Hot forged +Rough machined (black surface after Q/T)+ Turned (optional) | ||||||||

| 4.Typical Applications | ||||||||

| a.Statically and dynamically stressed components for vehicles | ||||||||

| b.Parts of larger cross-sections, crankshafts, gears | ||||||||

| c.Gears, stem assemblies, | ||||||||

| d.Pump shafts and tool holders | ||||||||

Product show

Workshop show

Shipping

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

Payment Terms

1.Payment: T/T, L/C, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before delivery.

2.MOQ: 1pcs

3.Warranty : 3 years

4.Package Informations: 1) EXPORT, In 20 feet (GW 25 ton) or 40 feet Container (GW 25 ton)

2)as customer's requirement

Why choose us?

(1) The leading exporter in China special steel industry.

(2) Large stocks for various sizes, fast delivery date.

(3) Good business relationship with China famous factories.

(4) More than 7 years steel exporting experience.

(5) Good after-sales service guarantee.

- Q: What are the disadvantages of using special steel?

- One of the main disadvantages of using special steel is its high cost. Special steel is typically more expensive to produce and purchase compared to regular steel. Additionally, the production process for special steel often requires specific techniques and equipment, which can further increase costs. Another disadvantage is the limited availability of special steel. It may not be readily accessible in all regions, leading to longer lead times and potential supply chain issues. Moreover, special steel may have lower formability and machinability compared to regular steel, making it more challenging to work with and shape as needed.

- Q: What are the different stamping grades of special steel?

- The different stamping grades of special steel include stainless steel, high-strength steel, tool steel, and alloy steel. Each grade has unique properties and characteristics that make them suitable for various stamping applications.

- Q: How is special steel used in the production of gears?

- Special steel is used in the production of gears due to its high strength, durability, and resistance to wear and fatigue. It provides the necessary toughness and hardness required to withstand the stresses and loads that gears experience during operation. Additionally, special steel can be heat treated to enhance its properties, ensuring precise dimensions and improving the overall performance and lifespan of gears.

- Q: What are the different certifications available for special steel?

- There are several certifications available for special steel, depending on the specific industry and application. Some of the commonly recognized certifications include: 1. ISO 9001: This certification ensures that the special steel manufacturer has implemented and maintained a quality management system that complies with international standards. It demonstrates the company's commitment to consistently providing products that meet customer requirements. 2. ISO 14001: This certification focuses on environmental management and ensures that the special steel manufacturer has implemented environmentally friendly practices in their operations. It demonstrates the company's commitment to reducing their environmental impact. 3. ASME (American Society of Mechanical Engineers) certifications: ASME offers various certifications for special steel used in pressure vessels, boilers, and other applications. These certifications ensure that the special steel meets specific quality and safety standards required by the industry. 4. PED (Pressure Equipment Directive): This certification is required for special steel used in pressure equipment in the European Union. It ensures that the steel meets specific safety and quality requirements. 5. NACE (National Association of Corrosion Engineers) certifications: NACE offers certifications for special steel used in corrosive environments. These certifications ensure that the steel has the necessary resistance against corrosion and can withstand harsh conditions. 6. API (American Petroleum Institute) certifications: API offers certifications for special steel used in the oil and gas industry. These certifications ensure that the steel meets specific quality and performance standards required for various applications in the industry. 7. ASTM (American Society for Testing and Materials) certifications: ASTM offers various certifications for special steel based on specific standards and specifications. These certifications ensure that the steel meets the required mechanical properties, chemical composition, and other criteria. It is important for manufacturers, suppliers, and end-users to consider these certifications when selecting special steel for their specific applications. These certifications provide assurance and confidence in the quality, safety, and performance of the special steel products.

- Q: How does special steel contribute to the ductility of products?

- Special steel contributes to the ductility of products by offering enhanced mechanical properties such as higher tensile strength and improved toughness. This type of steel is specially formulated with alloying elements that promote grain refinement and uniform microstructure, allowing the material to withstand greater deformation without breaking or cracking. Additionally, special steel often undergoes specific heat treatment processes that further enhance its ductility, ensuring that the final products can be easily shaped, bent, or stretched without compromising their structural integrity.

- Q: What are the properties of magnetic steel?

- Magnetic steel is characterized by its ability to attract and hold a magnetic field. It has a high magnetic permeability, allowing it to easily magnetize and demagnetize. Magnetic steel also exhibits high coercivity, meaning it has a strong resistance to losing its magnetization. Additionally, it possesses high electrical conductivity and is often used in various applications such as transformers, motors, and magnetic storage devices.

- Q: What are the limitations of using special steel in high-temperature applications?

- The limitations of using special steel in high-temperature applications include its susceptibility to oxidation and corrosion, reduced mechanical strength at elevated temperatures, and potential for thermal expansion and distortion. Additionally, special steel may be expensive and difficult to obtain, limiting its practicality in certain applications.

- Q: How does special steel perform in terms of high-temperature strength?

- Special steel performs exceptionally well in terms of high-temperature strength. It exhibits excellent resistance to deformation, creep, and oxidation at elevated temperatures, making it suitable for various applications that require stability and strength under extreme heat conditions.

- Q: What are the different impact-resistant grades of special steel?

- Steel alloys known as impact-resistant grades are designed to withstand high impact and shock loads without fracturing or deforming. These grades of steel are crucial in industries like construction, mining, automotive, and defense, where resistance to impact and toughness are essential. Numerous impact-resistant grades of special steel are available, each with its own unique characteristics and properties. Some commonly used grades include: 1. AR400: This steel has a hardness of 400 Brinell (HB) and is highly resistant to abrasion and impact. It finds applications in bucket liners, crushers, and hoppers where wear resistance is critical. 2. AR500: With a hardness of 500 HB, AR500 steel offers even greater resistance to wear and impact compared to AR400. It is frequently used in heavy machinery, mining equipment, and armored vehicles. 3. AR600: This steel boasts a hardness of 600 HB, making it one of the toughest and most impact-resistant options. It is ideal for applications that require extreme wear resistance and durability, such as chutes, conveyors, and ballistic protection. 4. T-1: T-1 steel is a high-strength, low-alloy (HSLA) steel that delivers excellent impact resistance and toughness. It is commonly utilized in structural components, heavy equipment, and offshore drilling rigs, where high strength and toughness are essential. 5. QT or Quenched and Tempered Steels: These steels undergo specific heat treatment to enhance their toughness and impact resistance. They are popular in applications that demand high strength, toughness, and impact resistance, such as gears, shafts, and armor plates. It is important to note that the impact resistance of a specific steel grade depends not only on its composition but also on factors like heat treatment, fabrication techniques, and design considerations. Therefore, consulting steel manufacturers or experts is crucial in determining the most suitable impact-resistant grade for a particular application.

- Q: What are the specific requirements for special steel used in the nuclear industry?

- To ensure the safety, durability, and reliability of special steel used in the nuclear industry, it must meet certain requirements. These requirements encompass the following: 1. Radiation Resistance: Special steel must exhibit high resistance to radiation in order to endure the intense levels present in nuclear reactors. This entails low neutron absorption and minimal degradation when subjected to irradiation. 2. Strength and Toughness: Given the extreme conditions in which nuclear reactors operate, special steel must possess exceptional strength and toughness to prevent structural failure under high temperatures and pressure. 3. Corrosion Resistance: Steel employed in nuclear applications must have a high resistance to corrosion, as exposure to corrosive environments can compromise the integrity of reactor components. This necessitates low susceptibility to stress corrosion cracking, intergranular corrosion, and pitting corrosion. 4. Impurity Content: Special steel must have a low impurity content to mitigate the risk of radioactive contamination. Impurities within the steel can activate and release radioactive particles, posing a significant safety hazard. 5. Thermal Stability: The steel must maintain its mechanical properties even under elevated temperatures, displaying excellent thermal stability. This ensures reliability and expected performance during prolonged exposure to high heat. 6. Non-Magnetic Properties: Certain nuclear reactor components require non-magnetic materials to prevent interference with sensitive instruments and equipment. Special steel used in these applications must possess non-magnetic properties to meet this requirement. 7. Regulatory Compliance: Special steel used in the nuclear industry must adhere to specific regulatory standards and certifications to confirm its suitability for use in nuclear facilities. These standards may vary by country or region, but generally involve rigorous quality control, testing, and inspection procedures. Compliance with these particular requirements is vital for maintaining the safety and integrity of nuclear reactors. By meeting these standards, special steel can withstand the harsh conditions and potential hazards associated with nuclear power generation.

Send your message to us

Special Steel 42CrMo Round Bar Steel SCM440

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords