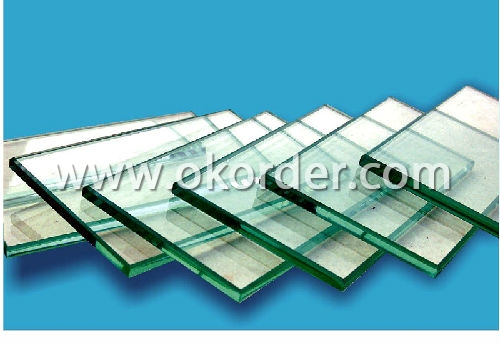

Clear Low-E Coated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single/Double Silver Low Radiation Coated Glass,energysaving,environmentfriendly, best lighting decorative materials

Features of Clear Low-E Coated Glass:

In winter, silver coatings will reflect heat back to the interior of the building to prevent heat loss; In summer, silver coatings will reduce the re-radiation of heat to make the interior of the building cooler.

solid coatingswill unite with glass into one.

the same lifetime of silver coatings with glass, stable properties, long storage.

easy to process, dispose and store

natural color

no need of special treatment as the layers of insulating glass

conforming to the standard of GB T 18915.2-2008

Specifications of Clear Low-E Coated Glass:

biggest size: 3660*2440mm/3660*2134mm (size is subject to customization)

thickness: 4mm,5mm,6mm,8mm

Applications of Clear Low-E Coated Glass:

It is widely used for constructon, decoration, curtain walls, windows, etc.

- Q: What chemicals can be made from glass, paper, detergents, etc?

- Glass: quartz, sodium carbonate, calcium carbonate paper: bark is enough.. cellulose + bleaching agent, such as activated carbon and other detergents, soap bar, sodium stearate

- Q: What is the raw material for making glass?

- The 60% component of the crystal is "two oxide" (SiO2). The color of the crystal is due to the addition of two silicon oxide, which also contains a variety of trace metals. In the natural environment, and most of crystal mineral calcite, pyrite, iron ore, Hui various colors of mica, Biqian, granite, Jin Hongshi and other "symbiosis", and formed some suspected imaginary scene, the so-called "different" like crystal, crystal increased collection of fun and value.

- Q: Who knows how the types of silicon sand are divided into types and what they are used for?

- With the progress of science development, composition and characteristics of glass and glass gradually get more understanding, research and development and production scale also has a good improvement, people can use a variety of silica sand quality production of a variety of uses a glass. Manufacture of optical glass, silica sand with high quality special glass, crystal glass, with medium quality silica sand production of flat glass, can also be used for sand production of colored glass, and according to the national defense and economic construction, research and development, production of various types of special glass

- Q: How is glass made? I heard that sand is used, but what is the concrete principle?

- Technological process:1, raw materials broken: the above raw materials broken into powder;2, weighing: according to the list of ingredients, called a certain amount of powder;3, will be called: the mixed powder mixing, stirring into a batch (colored glass and colorant);4, melting: the mixture into the glass furnace, melting at 1700 degrees into glass;5, forming: the glass liquid into a tin bath (float), pull machine (lattice method), rolling machine (rolling method, adding metal wire is wire glass), forming the flat glass;6, annealing: the molding of glass products into the annealing furnace annealing, balance the stress, to prevent self cracking.

- Q: What kind of raw material is glass made of?

- Composition of common glass chemical oxides (Na2O, CaO, 6SiO2)Glass is usually divided into oxide, glass, and non oxide glass by major components. Non oxide glass varieties and a small number, mainly sulfur glass and halide glass. Chalcogenide glass anion for sulfur, selenium and tellurium, can stop short wave light by yellow, red, and near infrared light, which has low resistance, switching and memory characteristics. Having low refractive index, low dispersion, and often used as optical glass.

- Q: Not man-made destruction, why toughened glass suddenly broken?

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

- Q: Why is toughened glass broken?

- This is because of containing nickel sulfide crystal glass raw material, manufacturing technology in the world is any existing can not be completely avoided, only reduce the exploding probability through control of the purity of raw materials and processing technology to a.It blew the concept of rate, the national standard of our country only glass project on the wall, I do not know whether the other foreign industry to use the toughened glass also has detailed provisions.

- Q: What material is used in the protective film in the middle of glass?

- At present, toughened glass membrane of glass raw materials generally have these brands. High end: Corelle & Schott. In the end: asahi. In the low-end: banxiaozi & luoyang.Just look different brands? The difference between JEANSWEST and Reaves? No, focusing on different materials.The same glass, medium and high-end glass called "aluminum silicon glass" in the low-end known as [sodium calcium glass]

- Q: How do I see whether the raw material of tempered glass is made of float glass or standard glass?!

- In the sun or under the light, look at the projection, float shadow is very weak, light transmission of good, lattice black lines, one by one

- Q: Use of glass flake cement

- Good temperature resistance. The use of glass scale lining, its heat resistance than similar resin coating can be increased by 20-40 degrees, so often used in oil pipelines, hot water pipelines, heat resistant chemical devices.

1. Manufacturer Overview

| Location | Shenzhen, China |

| Year Established | 1984 |

| Annual Output Value | |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen, China |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | High; Average |

Send your message to us

Clear Low-E Coated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords