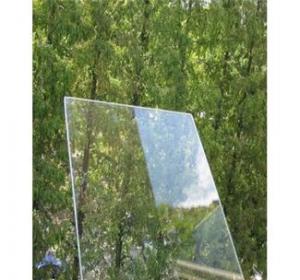

Online Low-E Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Low-E Glass is coated with low-E material-Silver, other low-E materials and metallic compound film over the surface of the glass, making the glass’s emissivity reducing from 0.84 to below 0.15. It not only has excellent energy efficiency, but also has decorative effects because of colors, and meanwhile has good processability (easy to be tempered, heat-strengthened, bent, insulating, laminated, etc.), thus becoming the first choice of architectural design. Theory for Energy Efficiency: By decreasing the U-value of glass and selectively lower the shading coefficient (Sc), It enables us to enhance the energy efficiency all sidedly.

Features:

According to the performance indexes, Low-E glass can be classified as single silver Low-E glass, double silver Low-E glass, treble silver Low-E glass

Single silver low-E glass: with higher visible light transmittance and extremely high far infrared reflectance as well as good cold and heat insulation, it is applicable to both the southern areas and the northern ones

Double silver low-E glass: it is high-end low-E glass with higher visible light transmittance and extremely low solar energy transmittance

It is applicable to the commercial buildings with high energy consumption and the glass doors of refrigerators and freezers

Treble Silver Low-E Glass: with lower shading coefficient, it has a stronger restrictive effect on the solar infrared thermal energy than double silver low-E glass. It is the top-grade glass in the field of energy efficiency and only applicable to the special regions with extreme weather (cold or hot) and particular requirements. It has the best energy efficiency, comfortableness and decorative effect.

Specifications:

Thickness: 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm and 19mm

Size:

2540 x 3300mm

2134 x 3300mm

2134*3600mm

2440 x 3660mm

6000 x 3300mm

12000 x 3300mm

Customized sizes

Applications:

Lowe-E Glass is widely used in glass curtain walls, energy-saving glass doors and windows because of its natural appearance and high transmittance. It is usually processed into insulating glass, the metal oxide coating contributes to the thermal insulation of windows and doors. In winter, silver coatings will reflect heat back to the interior of the building to prevent heat loss; In summer, silver coatings will reduce the re-radiation of heat to make the interior of the building cooler.

Due to its excellent thermal insulation, Low-E Glass can also be used in the fields such as ovens, refrigerator doors, wine cabinets, beverage cabinets, disinfection cabinets and other cabinets.

- Q: What chemicals can be made from glass, paper, detergents, etc?

- Acid: hydrochloric acid, sulfuric acid alkali: calcium hydroxide salt: soda ash, limestone, other: silica, mercury, lead and other small amounts of metal

- Q: How to distinguish between good and bad glass fiber reinforced plastic?

- Glass steel will be exposed his true strength in the actual use of the process, the quality of glass steel after a few years of use color slightly dim, the whole board intact, no obvious damage, glass steel it would withstand the test of practice, after a few years of use will appear corrosion fracture pores and other obvious damage the board is not so smooth, the color degradation is serious, the overall aging, general glass steel is to be used for twenty years, but two years later will appear glass steel inferior overall aging phenomenon, thus causing great losses to customers.

- Q: How can glass frosting be formulated? What raw materials do you use?

- The frosting frosting liquid before configured with plastic (or bamboo sticks) fully stir until frosting, and then prepare the medicine 80 mesh will be good all the time was filtered, the filtrate into the box (with sand sprinkling), filter residue (crystal) with plastic barrels (good to be frosted glass after the completion of the work, with 80 of the screen will put back the crystal installed frosting solution is dissolved, so repeated operation, the filter residue (crystal) can recycling, prolong the service life of frosting liquid).

- Q: How is glass made? What are the main ingredients?

- Preparation of batch. According to the product, the composition of the mixture is slightly different. For example, ordinary float glass batch (calculated in accordance with 1 weight boxes of 50 kilograms), need to consume 33.55 kg of quartz sand, limestone, dolomite, 2.96 kg 8.57 kg 11.39 kg of soda, Glauber's salt 0.55 kg, 3.45 kg, 0.03 kg of feldspar powder etc..

- Q: Polypropylene short fiber and glass fiber if different

- Polypropylene fiber is resistant to acid and alkali, and glass fiber has poor alkali resistance.

- Q: What's the raw material for organic glass fiber reinforced plastic? Thank you.

- Unsaturated resin, curing agent, catalyst, surface felt. There are alkali fiberglass cloth, mesh cloth, talcum powder or quartz sand. Colorant added according to product requirements. Bonus points!

- Q: What is glass fiber reinforced nylon?

- With excellent wear resistance, heat resistance and electrical properties, high mechanical strength, self extinguishing, good dimensional stability, widely used in automotive industry products, textile products, pump impeller and first class precision engineering componentsPA6 enhancement series:With good wear resistance, heat resistance, oil resistance and chemical resistance, but also greatly reduce the water absorption and shrinkage of raw materials, with excellent dimensional stability and excellent mechanical strength

- Q: What material can not be sprayed on the glass?

- If you want to spray characters on the glass, it is impossible to follow the glass unless it is frosted. If you really want to spray words on the glass, you can go directly to the print shop, do the word, and then stick it up.

- Q: The main raw material for the impact of float glass cost?

- Fuel prices: heavy oil, natural gas or coal, etc., because of the large number of long-term consumption, so it is also an important factor affecting product costs.

- Q: What kinds of ingredients are the glass?

- Is usually made of sand, sodium carbonate and calcium carbonate eutectic is prepared; also available mixture of sodium sulfate and sodium carbonate to replace carbon melting. Some other glass such as potassium glass, is a relatively high temperature, hard and chemical resistance of glass in molten glass with potassium carbonate to replace sodium or potassium sulfate prepared, mainly used in chemical container manufacturing laboratory commonly used.

1. Manufacturer Overview

| Location | Hunan,China |

| Year Established | 2005 |

| Annual Output Value | |

| Main Markets | Southeast Asia;Mid-East |

| Company Certifications | ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | 9333,333 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Online Low-E Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords