Silicone Rubber Coated Fiberglass Fabric for Thermal Insulation at High Temperatures

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRICE: USD12 per square meter

UNIT: square meter

MOQ: 500square meters

Width: 1m, 1.27m, 1.52m

Color: black

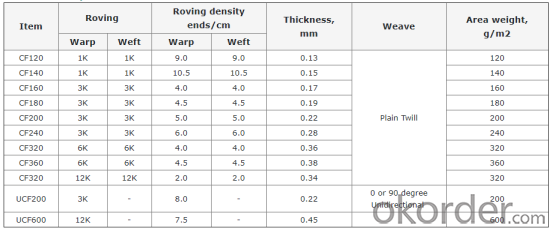

Weave Type:twill woven, plain woven

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Rolls packed In cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

Description: Carbon fabric is woven by carbon fiber yarn available with 1K,3K,6K,12K, 24K. Carbon fiber is known as super high strength, modulus and light weight. It is a outstanding reinforce material. Depends on the various quality of carbon fiber, there are available various fabrics.

Features: High strength and modulus, Excellent resin and adhesive compatibility, Flexible customized specification

- Q: Is fiberglass fabric resistant to moisture penetration?

- Yes, fiberglass fabric is resistant to moisture penetration. Fiberglass is made from thin strands of glass that are woven together to create a strong and durable fabric. The nature of glass fibers makes them highly resistant to moisture, as they do not absorb water or allow it to pass through easily. This makes fiberglass fabric an ideal material for applications where moisture resistance is important, such as in boat covers, outdoor furniture, and protective clothing. Additionally, fiberglass fabric is often used in areas where high humidity or water exposure is common, such as in bathrooms or swimming pools, due to its ability to resist moisture penetration.

- Q: Can fiberglass fabric be used for insulation in petrochemical facilities?

- Yes, fiberglass fabric can be used for insulation in petrochemical facilities. Fiberglass fabric is a commonly used insulation material due to its excellent thermal properties and resistance to high temperatures. It is capable of withstanding the extreme conditions found in petrochemical facilities, such as high heat, chemicals, and corrosive environments. Additionally, fiberglass fabric is lightweight, flexible, and easy to install, making it a convenient choice for insulation purposes. It also provides effective sound insulation, which can be beneficial in petrochemical facilities where noise reduction is important. Overall, fiberglass fabric is a suitable option for insulation in petrochemical facilities due to its durability, thermal efficiency, and versatility.

- Q: Can fiberglass fabrics be used for insulation in electrical systems?

- Fiberglass fabrics are capable of being used for insulation in electrical systems. Due to its exceptional thermal and electrical insulation properties, fiberglass is a widely utilized material for insulation. It possesses non-conductive characteristics, signifying its incapability to conduct electricity. This quality renders it perfect for incorporation in electrical systems necessitating insulation to avoid the leakage of electrical current or short circuits. Moreover, fiberglass fabrics exhibit remarkable resistance to high temperatures, which renders them suitable for utilization in electrical systems that generate heat. The fabric form of fiberglass facilitates effortless installation and wrapping around electrical components, thereby furnishing a protective barrier against electrical shocks and preventing the transfer of heat. To summarize, fiberglass fabrics represent a dependable and efficient option for insulation in electrical systems.

- Q: What are the different finishes available for fiberglass fabric rolls?

- There are several different finishes available for fiberglass fabric rolls, each providing unique characteristics and benefits. Some common finishes include: 1. Plain: Plain finish refers to fiberglass fabric without any additional treatment or coating. It offers excellent strength and durability, making it suitable for a wide range of applications. 2. Silicone: Silicone-coated fiberglass fabric rolls are popular due to their exceptional heat resistance and non-stick properties. This finish provides excellent release properties, making it ideal for applications involving high temperatures or sticky materials. 3. Aluminized: Aluminized finish involves applying a layer of aluminum to the surface of the fiberglass fabric. This finish offers excellent heat reflection properties, making it suitable for applications where heat insulation is required. 4. Vermiculite: Vermiculite-coated fiberglass fabric rolls provide enhanced fire resistance and heat insulation capabilities. The vermiculite coating expands when exposed to high temperatures, creating a protective barrier against heat and flames. 5. PTFE: PTFE (polytetrafluoroethylene) coating is often applied to fiberglass fabric to enhance its chemical resistance and non-stick properties. This finish is commonly used in applications involving corrosive chemicals or where easy release is required. 6. PVC: PVC (polyvinyl chloride) coating is applied to fiberglass fabric to provide additional protection against chemicals, oil, and moisture. It also offers increased strength and flexibility, making it suitable for various industrial applications. These are just a few examples of the finishes available for fiberglass fabric rolls. Depending on the specific requirements of an application, there may be additional finishes or combinations of finishes that can be utilized to meet the desired functionality and performance.

- Q: Glass fiber cloth and glass fiber?

- Glass fiber is a kind of inorganic nonmetallic material with excellent properties. English name is: glass, fiber or fiberglass. Composition of silica, alumina, calcium oxide, boron oxide, sodium oxide, Magnesium Oxide etc.. It is prepared by high temperature melting, wire drawing, winding and weaving process with glass balls or waste glass as. All kinds of products formed finally, glass fiber monofilament diameter from a few microns to twenty micron, the equivalent of a hair 1/20-1/5, each bundle of fibers are hundreds or even thousands of root root filaments, usually as a reinforcing material of complex materials, electrical insulating materials and insulation materials, circuit board, etc. and widely used in various fields of the national economy

- Q: Can fiberglass fabric be used for making molds?

- Yes, fiberglass fabric can be used for making molds. It is a popular choice due to its strength, durability, and ability to easily conform to different shapes. Fiberglass fabric is commonly used in the mold-making process to create lightweight, yet sturdy molds for various applications such as in the automotive, aerospace, and construction industries.

- Q: Can fiberglass fabric be used for reinforcement in underground storage tanks?

- Yes, fiberglass fabric can be used for reinforcement in underground storage tanks. Fiberglass fabric is known for its high strength-to-weight ratio and excellent corrosion resistance, making it an ideal choice for reinforcing underground storage tanks. It can provide additional structural integrity to the tank and help prevent potential failures or leaks. Furthermore, fiberglass fabric is easy to handle and install, making it a practical and cost-effective solution for reinforcing underground storage tanks.

- Q: What are the cracks between the brick wall and the beam column, the cracks between the planks and the cracks in the plasterboard?

- You describe these cracks, are essentially composed of different materials in the influence of temperature and humidity of the physical changes now to solve this kind of problem is late with ductile material recovery, wall and ceiling like corner cracking the case, that is to do the above method.

- Q: Can fiberglass fabric be used for medical devices?

- Yes, fiberglass fabric can be used for certain medical devices. Fiberglass fabric has several properties that make it suitable for medical applications. It is lightweight, flexible, and has a high strength-to-weight ratio, making it ideal for devices that require durability and support. Additionally, fiberglass fabric is non-toxic and non-allergenic, which is crucial for medical devices that come into contact with the human body. It can be used in various medical applications such as orthopedic braces, prosthetics, casts, and splints. However, it is important to note that fiberglass fabric should be properly sterilized and tested for biocompatibility before being used in medical devices to ensure it meets the necessary safety standards.

- Q: The difference between the projection screen and glass bead?

- Fiberglass fabric: a curtain made of fiberglass woven fabric with a good flatness. Gain value: around 1.1, viewing angle: about 160 degrees. Its good smoothness, with suitable prices, applies to a variety of occasions.

Send your message to us

Silicone Rubber Coated Fiberglass Fabric for Thermal Insulation at High Temperatures

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords