Silicon Carbide Ceramic Filter Plate Foam Filters Lower Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Ceramic Foam Filter :

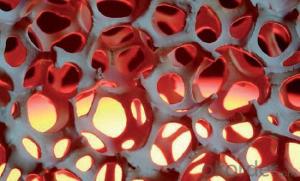

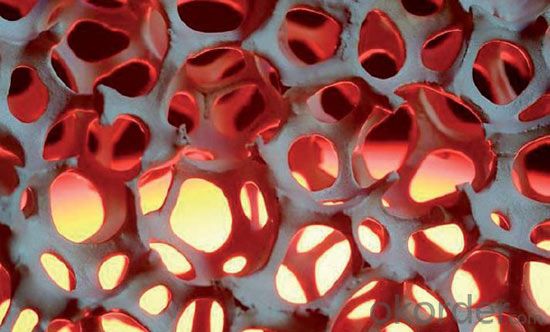

Silicon carbide ceramic foam filters are mainly designed to improve the quality of iron castings. The filter can effectively remove non-metallic inclusions slag and dross from the molten metal stream.

2.Main features of Ceramic Foam Filter:

◆ Excellent thermal shock resistance

◆ Good strength under high temperature

◆ Improving casting quality

◆ Reducing turbulence in gating system

◆ Tailored sizes as customers requirement

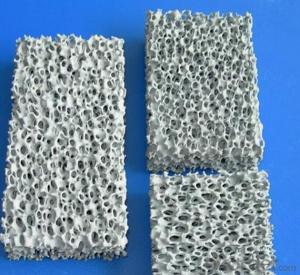

3. Ceramic Foam Filter Images:

4. Ceramic Foam Filter Technical Parameters

There are four kinds of ceramic foam filter according to different usages.

They are Silicon Carbide Ceramic Foam Filter, Zirconia Ceramic Foam Filter, Alumina Ceramic Foam Filter, Magnesia Ceramic Foam Filters.

Application

Grey iron casting, ductile iron casting, precious metals casting

Copper casting, bronze casting, brass casting

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our ceramic fiber products?

A world class manufacturer & supplier of ceramic fiber product is one

of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 80000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What filter material are placed in the aquarium filter?

- Generally let off the filter cotton and ceramic rings, there are biochemical balls, coral bone, stone, activated carbon and so onConditional: filter cotton, ceramic ring, biochemical ball, coral bone, stone, activated carbon

- Q: Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- The spindle speed is too fast.The speed is too high to absorb the filter cake.There are other possible reasons.

- Q: What are the materials that make up the ceramic mold?

- At present, the commercialized porous ceramic membranes are mainly composed of 3 types: flat plate, tubular and multi channel. Flat film is mainly used for small-scale industrial production and laboratory research. The tubular membrane is combined with rice to form a heat exchanger similar to a column tube heat exchanger, which can increase the loading capacity of the membrane, but is gradually withdrawn from industrial application due to its strength problem. The size of the applied ceramic membrane usually adopts a multi channel configuration, that is, a plurality of channels are distributed on a circular cross-section, and the number of general channels is 7, 19 and 37. The main business of the inorganic ceramic membrane preparation technology: using solid particle sintering preparation carrier and microfiltration membrane by sol-gel method in the preparation of ultrafiltration membrane: glass membrane by phase separation method: using special technology (such as chemical vapor deposition, electroless plating, etc.) the preparation of microporous membrane or dense membrane. Its basic theory involves colloid and surface chemistry, material chemistry, solid state ion science, material processing and so on.

- Q: How much is the accuracy of 50nm ceramic membrane filtration?

- 50nm refers to the nominal pore size, but it does not mean that the holes in the ceramic membrane are 50nm, but the approximate number of holes. The size of the pores may be between 40~60 and 45 to 55nm. Generally introduced, annotated range, you can also own to detect.

- Q: Does the ceramic factory use hydrochloric acid?

- In order to avoid the possibility of plugging, ceramic filter plates with suitable aperture range of different manufacturers can be selected.

- Q: Ceramic filter cleaning, sulfuric acid cleaning

- Can be washed with chromic acid lotion. The effect is better

- Q: How can I avoid the backwash pressure in the production of ceramic filter?

- Recoil of the ceramic filter is on the clean water under certain pressure, from the inside out flushing blockage blockage in the ceramic filter plate on the internal pore water pressure, the recoil is generally less than 0.12MPa, the pressure is too small or no recoil recoil effect is not good.

- Q: Ceramic filter suddenly do not smoke, a little later on their own good, what reason?

- The size of ceramic filter is generally on both sides of the vacuum tank, such as 50 square meters with 5 square meters of ceramic filter / ring ceramic filter plate combination (possible), there are 10 discs, the ceramic plate left a vacuum tank on the left of the 5 disc for filtration, vacuum filtration tank for the ceramic plate on the right right of the 5 disc. If a vacuum system temporarily fails, it may cause poor suction, no suction, and a normal operation at the other end.

- Q: Beneficiation ceramic filter no problem, the technical parameters are normal, but filter out the concentrate water suddenly excessive, what is the reason?

- First, the fineness of the material, resulting in the filter board filter cake moistureTwo, the vacuum can not reach, in the circumstances, whether the vacuum pipe leak

- Q: What about the leakage of the ceramic filter static and dynamic sealing points?

- When the ceramic filter works, the operation may be as follows: 1. The feed is injected and the pulp is injected into the tank of the ceramic filter. 2, mixing system, ceramic filter stirring rake back and forth mixing, driven by mixing reducer. 3, spindle rotation, material level reached a certain range, through the spindle speed machine to drive the ceramic filter disk rotation.

Send your message to us

Silicon Carbide Ceramic Filter Plate Foam Filters Lower Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords