Silica Brick - Refractory Silica Insulation Fire Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

Our silicon insulation brick is made of baked crystalline silica as raw material by adding into compound flammable substance. This product has low thermal conductivity, high refractoriness

under load, residual expansion trace, excellent variability of re-burning line and other characteristics, which is widely available for heat-insulating layer of various high-temperature furnace equipments not in contact with molten slag under high temperature condition (≤1,500 ℃).

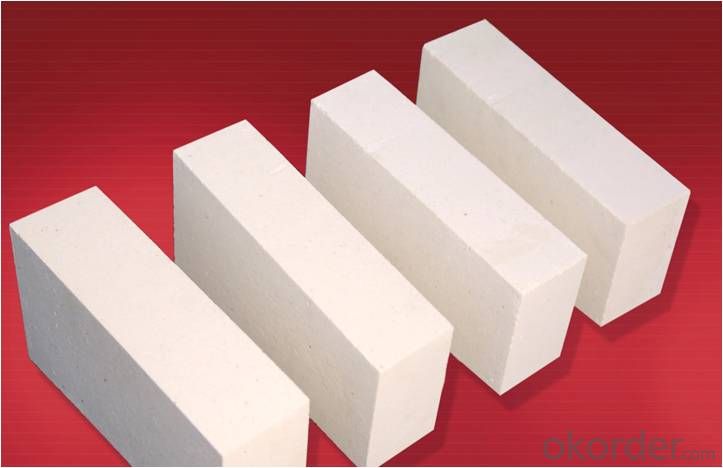

With dense and smooth appearance, uniform corner and edge, pure color and luster and accurate size.

1) Silicon oxide is above 95%.

2) Good acid erosion resistance.

3) High softening point with temperature.

4) No shrink in burn repeatedly.

5) Temperature of refractoriness under load is above 1650º C

Typical Application

Light- weight Insulating Brick can be used as a hot surface or other refractory refractory insulation support, used for melting furnace, ignition furnace, flue, refining equipment, heating equipment and piping, regeneration device, gas furnace, soaking furnace, annealing furnace, heat reaction chamber and other industrial equipment.

Advantage of Insulating Brick

Light- weight Insulating Bricks are made from refractory clay as the main raw material of the AL2O3 content is 30% ~ 48% of the heat insulation refractory brick. The production process adopts the burn out of character and bubble method. With refractory clay, drift beads, refractory clay clinker as raw material, adding binder and sawdust, the ingredients, mixing, molding, drying, firing, volume density was 0.8 to 1.5 g/cm3.

Technical Data

| ITEM | General silica bricks | Hot Air Oven silica bricks | |||||

| GZ-95 | GZ-94 | GZ-93 | Vaults furnace bricks | checker bricks | |||

| SIO2 %Min | 95 | 94 | 93 | 95 | 96 | 95 | 96 |

| Fe2O3 %Max | 1.2 | 1.4 | 1.5 | 1.0 | |||

| Refractoriness °C | 1710 | 1710 | 1690 | 1710 | 1710 | 1710 | 1710 |

| 0.2 Mpa load softening temperature began °C p | 1650 | 1640 | 1620 | 1650 | 1660 | 1650 | 1660 |

| Porosity % | 22 | 23 | 25 | 22 | 22 | 22 | 22 |

| Normal temperature compression strength Mpa p | 29.4 | 24.5 | 19.6 | 35 | 40 | 30 | 35 |

| Bulk Density Min(Kg/m3) | 0.9 | 0.8 | 0.8 | 1.0 | |||

Photos for Workshop

- Q: The introduction of silica brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass

- Q: Physical solid waste disposal

- Too much addition will reduce the refractory and mechanical strength, increase porosity, so the amount of waste brick should not be too much.

- Q: Because of the recent relates to this industry, by way of learning to name for all raw materials, I hope knowledgeable friends exhibitions, thank you.

- Acidic materialMainly siliceous materials, such as quartz, tridymite and cristobalite, chalcedony, flint, opal, white quartzite, silica sand, diatomaceous earth, silicon oxide contained in these siliceous materials (SiO2) at least 90%, pure raw materials are silicon oxide as high as 99% or more. Siliceous materials at high temperature is the acidic nature of chemical dynamics, when the presence of metal oxide, or when in contact with the chemical reaction, and combined with a fusible silicate. Therefore, if there is a small amount of metal oxide in siliceous material, it will seriously affect its thermal resistance.

- Q: Why will expand when heated brick

- Because the production of raw materials are silica brick, brick with SiO2 content of not less than 95% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system

- Q: The introduction of silica brick

- Brick refers to the content of more than 93% products SiO2. Brick with SiO2 content of not less than 96% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system. The higher the content of SiO2 in silica raw material, the higher the refractoriness of the product. According to the use of brick varieties, divided into: coke oven silica brick, brick for hot blast stove, electric stove with brick, brick for glass furnaces. According to the transformation is divided into: standard bricks, tiles, bricks and general special brick etc..

- Q: Semisilica brick interpretation

- High temperature volume stability. Volume change is small.

- Q: How much is the highest melting point of silicon?

- Acidic silica brick refractories, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature. More than 94% silica content.

- Q: The United States of our brick anti-dumping duties?

- . According to the relevant legal procedures, the United States International Trade Commission will make a final ruling on the anti dumping industrial injury before January 6, 2014, if an affirmative determination, the U.S. Department of Commerce will be involved in product release tax anti-dumping order.

- Q: Brick

- Acidic silica brick refractory material, has good acid resistance and slag erosion, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature.

- Q: Physical solid waste disposal

- Too much addition will reduce the refractory and mechanical strength, increase porosity, so the amount of waste brick should not be too much.

Send your message to us

Silica Brick - Refractory Silica Insulation Fire Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords