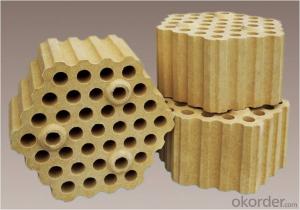

Silica Brick for Hot Blast Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief discription for Silica Bricks for Hot Blast Furnace

CMAX Silica Bricks are classified according to alumina content ranging from 48% to 90%.

CMAX Silica Bricks are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln,regenerator, etc.

Brief features for Silica Bricks for Hot Blast Furnace

◆Low thermal conductivity

◆Excellent acid and base slagging resistance

◆High refractoriness

◆Excellent thermal shock resistance

◆Excellent mechanical strength

◆Good spalling resistance and wear resistance.

◆Good corrosion resistance.

◆High-temperature creep rate is quite low.

◆Good volume stability at high temperature.

◆Low bulk density, low thermal conductivity, good thermal insulation performance.

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- Small fluctuations in the chemical composition do not have a significant effect on use. The key is the operation of the electrolyzer in production to determine whether the side wall will be damaged.

- Q: Why is the new trend of the high thermal conductivity of silica brick

- The use of high thermal conductivity of silica brick, reducing coke fuel consumption, reduce emissions of pollutants such as NOx, with considerable economic benefits and social benefits, is the future direction of the new technology of using coke oven refractory.

- Q: Such purpose and scope please give me detailed points thank you because I am learning stage

- Mainly used for coke oven carbonization chamber and the combustion chamber wall, open hearth furnace regenerator and a sediment chamber, soaking furnace, glass furnace, refractory materials and ceramic brick kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace.

- Q: What is the main material of silica brickIt's common, the kind we see so often!

- More than 94% silica content. True density 2.35g/cm3. With acid resistance, slag erosion performance.

- Q: Which material is good for furnace refractory?

- Kiln types of refractories is very extensive, selection of refractory materials according to the type of furnace furnace temperature and use of selected refractory material, refractory material is divided into custom products of refractory bricks and unshaped refractory castable series products. According to chemistry, it is divided into acidic, neutral and alkaline materials.

- Q: Why is the three oxidation of two silicon is very harmful impurities in silica brick

- Can generate the material needs is the best way to see the impurity problem!! the first consideration is whether can get the material impurities with what method choice after the time! Miscellaneous reactions cannot have new impurity formation! Selected cannot and need material reaction reagent!

- Q: Can not use it two brick

- Acidic silica brick refractory material, has good ability in acid slag erosion

- Q: Brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass. Tridymite and cristobalite and quartz remaining at low temperature due to phase change, volume changes greatly, so the brick thermal stability at low temperature is very poor. In use, under 800 degrees Celsius, slowly heating and cooling, so as not to produce cracks. The use of temperature in blast furnace so should not be below 800 DEG on.

- Q: Why in the production of the brick to detect the volume density

- Density is the property of material, different density of materials, density of the same kind of material is not up to standard, affecting performance.

- Q: High temperature refractory material?

- Basic refractories in Magnesium Oxide and calcium oxide as the main component, the main products are magnesia brick, magnesia chrome brick, magnesia zirconia brick, magnesia brick, magnesia spinel brick, magnesia calcium brick, dolomite brick and the latest development of magnesia spinel brick and so on. With Magnesium Oxide (MgO) more than 80% of the refractory brick called magnesia brick,

Send your message to us

Silica Brick for Hot Blast Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords