SIH:S hydraulic system Excavator SH130-5

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of excavator:

Excavators are heavy construction equipment consisting of a boom, stick, bucket and cab on a rotating platform known as the "house". The house sits atop an undercarriage with tracks or wheels. A cable-operated excavator uses winches and steel ropes to accomplish the movements. They are a natural progression from the steam shovels and often called power shovels. All movement and functions of a hydraulic excavator are accomplished through the use of hydraulic fluid, with hydraulic cylinders and hydraulic motors. Due to the linear actuation of hydraulic cylinders, their mode of operation is fundamentally different from cable-operated excavators.

Modern, hydraulic excavators come in a wide variety of sizes. The smaller ones are called mini or compact excavators. For example, Caterpillar's smallest mini-excavator weighs 2,060 pounds (930 kg) and has 13 hp; their largest model is the largest excavator available (a record previously held by the Orenstein & Koppel RH400) the CAT 6090, it weighs in excess of 2,160,510 pounds (979,990 kg), has 4500 hp and has a bucket size of around 52.0 m³ depending on bucket fitted.

Engines in hydraulic excavators usually just drive hydraulic pumps; there are usually 3 pumps: the two main pumps are for supplying oil at high pressure (up to 5000 psi) for the arms, swing motor, track motors, and accessories, and the third is a lower pressure (700 psi) pump for Pilot Control, this circuit used for the control of the spool valves, this allows for a reduced effort required when operating the controls.

Specifications of excavator:

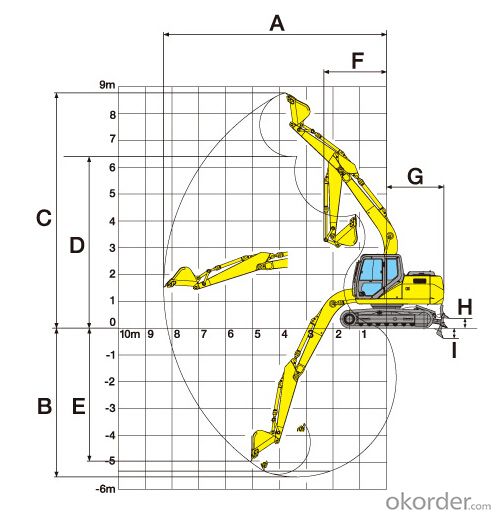

Working Range

| Arm length | 2.23 m | 2.62 m | 3.05 m |

|---|---|---|---|

| Boom length | 5.15 m | ||

| A ( Max.digging radius ) | 8 670 mm | 9 040 mm | 9 380 mm |

| B ( Max.digging depth ) | 5 660 mm | 6 060 mm | 6 490 mm |

| C ( Max.digging height ) | 9 010 mm | 9 240 mm | 9 290 mm |

| D ( Max.dumping height ) | 6 380 mm | 6 610 mm | 6 690 mm |

| E ( Max.vertical wall cut depth ) | 4 720 mm | 5 080 mm | 5 220 mm |

| F ( Min.front swing radius ) | 2 980 mm | 2 990 mm | 2 980 mm |

| G ( Rear end swing radius ) | 2 450 mm | 2 450 mm | 2 450 mm |

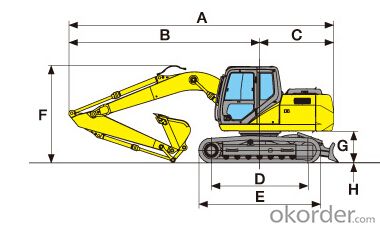

Dimensions

| SH160-5 | |||

|---|---|---|---|

| Arm length | 2.23 m | 2.62 m | 3.05 m |

| A Overall length | 8 490 mm | 8 440 mm | 8 520 mm |

| B Length from center of machine (to arm top) | 6 080 mm | 6 030 mm | 6 110 mm |

| C Upper structure rear end radius | 2 450 mm | 2 450 mm | 2 450 mm |

| D Center to center of wheels | 3 190 mm | 3 190 mm | 3 190 mm |

| E Overall track length | 3 990 mm | 3 990 mm | 3 990 mm |

| F Overall height | 3 000 mm | 2 960 mm | 3 130 mm |

| G Clearance height under upper structure | 1 020 mm | 1 020 mm | 1 020 mm |

| H Shoe lug height | 26 mm | 26 mm | 26 mm |

| I Cab height | 2 930 mm | 2 930 mm | 2 930 mm |

| J Upper structure overall width | 2 540 mm | 2 540 mm | 2 540 mm |

| K Width from center of machine (left side) | 1 290 mm | 1 290 mm | 1 290 mm |

| L Width from center of machine (right side) | 1 250 mm | 1 250 mm | 1 250 mm |

| M Track gauge | 1 990 mm | 1 990 mm | 1 990 mm |

| N Overall width | 2 590 mm | 2 590 mm | 2 590 mm |

| O Std.Shoe width | 600 mm | 600 mm | 600 mm |

| P Minimum ground clearance | 440 mm | 440 mm | 440 mm |

| Q Handrail height | 2 950 mm | 2 950 mm | 2 950 mm |

Principle Specifications

| SH160-5 | ||

|---|---|---|

| Base | Boom length | 5.15m |

| Arm length | 2.62m | |

| Bucket capacity (ISO heaped) | 0.62m3 | |

| Std.operating weight | 16 900kg | |

| Engine | Make & model | lSUZU AI-4JJ1X |

| Rated output | 89.2kW/2200 min-1 | |

| Piston displacement | 2999ml(cc) | |

| Hydraulic System | Main pump | 2 variable displacement axial piston pumps |

| Max. pressure | 34.3 Mpa | |

| (with auto power boost) | 36.3 Mpa | |

| Travel motor | Variable displacement axial piston motor | |

| Parking brake type | Mechanical disc brake | |

| Swing motor | Fixed displacement axial piston motor | |

| Performance | Travel speed | 5.4/2.8 km/h |

| Traction force | 161 kN | |

| Grade ability | 70%<35º> | |

| Ground pressure | 40 kPa | |

| Swing speed | 11.5 min-1 | |

| Bucket | 112 kN | |

| /with power boost | 118 kN | |

| Arm | 79 kN | |

| /with power boost | 84 kN | |

| Others | Fuel tank | 300 liter |

| Hydraulic fluid tank | 90 liter | |

Images of excavator:

FAQ of excavator:

Q: What are the main functions of excavators?

A: Excavator is the machine that can excavate the the soil of various types forcefully and then using hydraulic system a hydraulic force is generated and utilizing this force bucket is exchange with some other attachments then excavator can be used for multi-purpose. For exemple pile diver, hydraulic jack hammer etc...

Q: What are the main type of excavators?

A: Crawler excavator; Wheel excavator;

Q: What is the application of excavators?

A: The excavator has increased the work speed tremendously. It is used extensively in numerous fields, including the following:

•Wood removal in forests

•Normal grading work and landscaping

•Cutting of brushes with attachments

•Demolition of structures, and removal of debris

- Q: i been playing the new moon map with my friends i know how to stop the excavator but in round 26 both excavators came down wich i tought there was not going to be any problem because on the next round i was going to stop both with the hacking device so we went te teletransport and went to area 51 than teletransport to the excavator station where you suppose to stop them i did stop both of them than changed my hacking device for the mask than i went to tunel 6 and the scavator was not all the way up so i went to tunel 11 and the same it was not all the way up idk why this happend so there was not a way to get to the dome where me and my firends camp and that was it we only made it to round 29.have this happend to you? why this happend?

- I had something similar once when I played with my friend. We couldn't find a way to get back to the dome, so we just decided it best to sacrifice a perk and let the astronaut guy hopefully teleport us to the other side of the excavators lol.

- Q: What can an excavator do?

- More, go, dig the ground, repair the slope, dig trenches, dig the floor, build roads, load cars, and so on...

- Q: Which bedding is better for my milk snake sand like their natural or what other substance can i use her is a web page of the sand which is brand better.

- you are able to desire to feed one properly sized nutrition merchandise. you will degree via way of the main extreme width of your snake's physique. If a pinky is basically too small, bypass to fuzzies. The length might desire to be no wider than a million a million/2 situations the widest part of the physique. Milksnakes do no longer consume slugs, earthworms and a few component. they might initiate on lizards interior the wild, regardless of the incontrovertible fact that they consume mammals and often diverse snakes as their cousins the kingsnakes do.

- Q: I also need a couple of different ways they found and mined the gold.

- The okorder /

- Q: Can someone give me a brief run through of how to calculate soil excavation as my searching on the net is proving unsuccessful. The area is 180x60x6 which equals 64800m3. The bulk factors are 1.3 for clay and 1.15 for fill material. The excavator has a peak output of 180 cubic meters per hour.What is the sum to incorporate the bulking factors into the equation to get a more realistic load of soil that needs to be excavated.Thanks

- It seems the question is not complete, I think the ratio of clay and fill material is required, the bulk factors here is the clay density which is 1300 kg/m^3 , and fill material is 1150 kg/m^3 . As the total soil volume is 64800 m^3 and excavator efficiency is 180 m^3 per hour , then the total time is 64800/180 = 360 hours

- Q: We have a farmer behind our house and whenever he floods his field for multiple days at a time it gets into our basement due to waterlevel issues. We have a sump pump but it is coming in along some of the walls of the basement and getting carpet wet. WE have fans on it right now and it should be ok for now. We've tried talking to the farmer before but he doesn't give a crap because he is an old angry man ( i hate him so much) So I am wondering if there is anyway we can make him only water every 3 days or so because he won't listen to reason. It is also causing problems for some of our neighbors so would it be possible to get like a petition and turn it in to the city? would that work?or what else can we do!?!?thanks!

- There's probably nothing you can do to make the farmer cut back or stop watering if the watering is part of earning his living. What you need to do is hire an excavator to dig out around your foundation. There is a product that is sprayed onto the exterior foundation walls - looks like rubberized tar - that will seal your foundation against leaks. This won't be cheap, but it will be a permanent fix. It would be a good idea to do this anyway. When the farmer quits farming, you may still have water issues in your basement unless you seal the basement walls. This should have been done when the house was built, but it's water over the dam now. I don't know if applying a sealer on the inside of the basement walls will work. The water will tend to push the sealer away from the interior wall. But you can try a small area to see how it works.

- Q: The excavator won't hit the car

- The 1 key to open the instrument is normal, there is no 2 starter reaction speed is enough, before the 3 switch is back to 4 have no reaction force start 5 is repaired 6 other things if you confirm the normal oil, many oil, diesel oil pump and nozzle to normal. New battery. Normal intake. It may be the wrong circuit, check the circuit should be 1 key to open the instrument is normal, there is no 2 starter reaction speed is enough, before the 3 switch is back to 4 have no reaction force start 5 is repaired 6 other things if you confirm the normal oil, many oil, diesel oil pump and nozzle normal. New battery. Normal intake. That could be a faulty circuit,

- Q: everyone says that if you open 6 first it will excavate it before the other ones. i always open excavator 6 1st but the excavator nevers turns on or it does #11. plz help

- Where the excavator breaches is largely based on luck, but it is more likely that it will breach tunnels you have opened already. I have also found that opening to the power room at round one will cause the excavator to breach at round one sometimes. Hope this helps!

- Q: Regarding fuel efficiency, performance on site, low maintenance, availability of replacement parts, etc.

- That is an impossible question to answer. It would depend too much on where you were, what you were doing and how heavily you weighted each of the criteria. But then that's true for just about any what's the best... type of question. There may be a best choice for one person in one particular situation but it is very rare that there is a clear best choice for all situations.

- Q: I've noticed that my female leos dish is always full. I've counted them, and she hasn't eaten any of her mealworms. I have her on excavator clay (I'm digging it out soon and doing paper towel sub. ).I checked her belly and theres no dark spots or weird lumps, so I think impaction is out of the question. I caught her drinking. Also, she looks into the bowl from time to time, however she doesnt eat the worms. Maybe she doesnt want them. I recently started adding carrot pieces and lil sprinkles of flukers cricket feed into the bowl with the worms. Does she not like that maybe?Tomorrow I'm going to try wax worms.She has not lost any weight in her tail...nor mid section (shes a chunky monkey). However shes been off feed for almost 3 days.I gave her a warm water bath and rubbed her sides.Also hasnt pooped since she last ate.Are leos known for going off feed for short periods of time?

- She ate! I gave her some small mealies I feed my baby and she ate them. Im a happy momma now.

Send your message to us

SIH:S hydraulic system Excavator SH130-5

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords