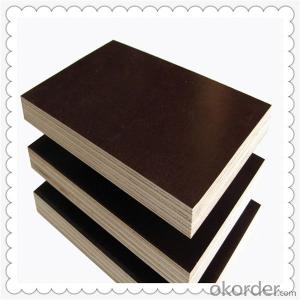

Brown Film Faced Plywood 18MM Jointed Core

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

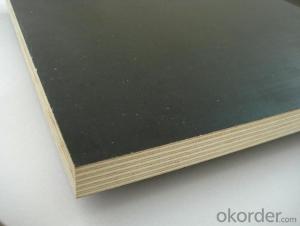

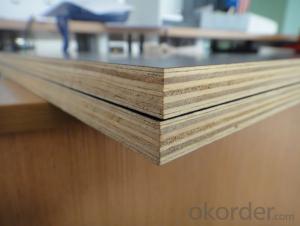

Item Name:Film Faced Plywood/Shuttering Plywood

Size:1220x1440mm,1250x2500mm

Thickness:9mm,12mm,15mm,18mm,20mm,25mm,other thickness as requested

Description

| Name | Film faced plywood,formwork plywood,shuttering plywood,marine plywood | ||

| Place of Origin | Shandong, China | ||

| Face/back | Black film,chinese brown film,imported brown film,red film,yellow film | ||

| Finish | Smooth,mesh(anti-slip),with or without logo | ||

| Core | eucalypts ,Poplar, Hardwood, Hardwood Combi, Birch, as your requirement. | ||

| Glue | MR,melamine WBP,Phenolic WBP | ||

| Thickness | 6mm, 9mm, 12mm, 15mm, 18mm, 21mm or as per request | ||

| Tolerance | +/-0.5mm | ||

| MOR/MOE | MOR ≥30Mpa;MOE ≥6000Mpa | ||

| Moisture | Less than 14% | ||

| Density | poplar:530~500kgs/cbm,hardwood:600~580kgs/cbm | ||

| Edges | Four edges will be sealed with water-proof paint(red, green or others) | ||

| Usage | Ideal concrete construction materials | ||

| Packing | Inner packing:0.2mm thickness plastic bag | ||

| Outer packing:pallet with carton and strpped with steel tape | |||

| Delivery | Within 15-20days after receiving deposit or original L/C at sight. | ||

| Payment | L/C at sight ,TT | ||

| Min order | 21 m3 | ||

| Supply ability | 8000-10000CBM per month | ||

| Additional | Sample available | ||

| Load quantity | 1*20GP | 8 pallets/21M3 | |

| 1*40GP | 16 pallets/42M3 | ||

| 1*40HC | 18 pallets/53M3; | ||

| Features: | |||

| 1.High bending strength | |||

| 2.Moisture-proof and easy work | |||

| 3.Tight construction and high strength | |||

| 4.No ratten or decay | |||

| 5.Low formaldehyde emission | |||

Features

1) Good Raw Materials and High quality

2) More repeated using times

3) Good packing and fast shipment

4) Delivery the right products according to different level of requirement

5) High performance/price ratio

FAQ

1.What's your company property ?

More than 10 factories to meet your various needs.

2.Free samples ?

Samples are free. As for the cost of courier , we will give back to you in the payment of the trial order .

3.What's your delivery time ?

The goods will be deliveried wthin 15 days after recepit of the deposit .

Products Photos

- Q: What are the allowable quantity differences in printed packaging materials?

- Large areas of the current general offset printing, letterpress printing and other printing methods, the size of the largest paper size, the entire area of more than a full sheet size, it is limited by mechanical equipment. Screen printing can be a large area of printing, screen printing products today can reach up to 3 meters x 4 meters, or even higher significantly.

- Q: What's the printing process for PC material? Is the print content on PC or other surfaces?

- As a screen printing material, semi automatic screen printing machine for printing or anti India, in particular circumstances, is usually anti India, India will.

- Q: Carton printing process and materials

- Single-sided corrugated production line adopts plastic gravure printing process composite paper carton packaging, paper printing also need to be completed if the light coating film, and large volume production, can be printed on the paper, and the way for gravure printing gravure printing on plastic film, and with white plastic film and paper and then the first printed composite, and then complete the box according to the conventional carton forming process.The process is characterized by:(1) the cost of making cartons is low. When the production batch is large, the printing cost and the material cost of the facial tissue can be greatly reduced by the process. Because the paper does not need to be printed, the uncoated white board paper can be used so as to greatly reduce the cost of the facial tissue.(2) beautifully printed. Because the plastic gravure printing is adopted, the printing effect can be compared with the offset printing effect. The process requires special attention. In the process of printing, it is necessary to take full account of the plastic film size changes and deformation; otherwise, the carton paper will be inconsistent with the lower paperboard.

- Q: What are the materials used in screen printing?

- The range of screen printing applications is very extensive. In addition to water and air (including other liquids and gases), any object can be used as a substrate. Some people have evaluated silk screen printing as saying: "if you want to find the ideal printing method on the earth to achieve the purpose of printing, it is probably screen printing method.".

Send your message to us

Brown Film Faced Plywood 18MM Jointed Core

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords