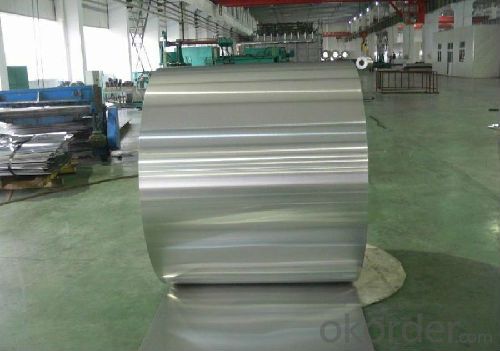

Sheets of Swirl Brushed Aluminum Coil and Sheet 1050 1100 3003 H14 H24 O

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Coil Discription

1. | Item | aluminum coil | |

2. | Standard | ASTM B221M, GB/T 3191, JIS H4040, etc. | |

3. | alloy | 1050 1200 1060, 1100, 1200, 3003, 3004 | |

4. | Temper | O H12 H14 H16 H18 H19 H22 H24 H26 H28 | |

5. | Specifications | thickness | 0.2--10mm |

Width | 90--2200mm | ||

Coil ID | 505mm 508mm 605mm 405mm 610mm 300mm | ||

6. | Surface | Mill finish, polished, mirror finish anodizing, brushing, sand blasting, powder coating, etc. | |

7. | Price Term | Ex-work, FOB, CIF , CFR, etc. | |

8. | Payment Term | T/T, L/C | |

9. | Delivery Time | According to order’s quantity. | |

10. | Package | Export standard package: bundled wooden box, suit for all kinds of transport, or be required. | |

11. | Application | 1) Kitchenware, food and chemical products processing and storage devices; 2) Aircraft fuel tanks, oil pipe, rivets, wire; 3) Cans cover, car body panels, steering plates, stiffeners, brackets and other components; 4) Manufacturing trucks, tower building, ship, train, furniture, machinery parts, precision machining with the tubes, rods, shaped, sheet metal. | |

12. | Contact | If you have any question, please feel free contact CNBM. | |

Chemistry Composition & Mechanical Properties

Chemistry Composition of aluminum coil | |||||||||

alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

1050 | 0.250 | 0.400 | 0.050 | 0.050 | 0.050 | - | 0.050 | 0.030 | 99.5 |

1060 | 0.250 | 0.350 | 0.050 | 0.030 | 0.030 | - | 0.050 | 0.030 | 99.6 |

1070 | 0.200 | 0.250 | 0.040 | 0.030 | 0.030 | - | 0.040 | 0.030 | 99.7 |

1100 | Si+Fe:0.95 | 0.05-0.2 | 0.050 | - | - | 0.100 | - | 99.0 | |

1200 | Si+Fe:1.00 | 0.050 | 0.050 | - | - | 0.100 | 0.100 | 99.0 | |

1145 | Si+Fe:0.55 | 0.050 | 0.050 | 0.050 | - | 0.050 | - | 99.45 | |

3003 | 0.600 | 0.700 | 0.05-0.20 | 1.0-1.5 | - | - | 0.100 | - | remains |

3004 | 0.300 | 0.700 | 0.250 | 1.0-1.5 | 0.8-1.3 | - | 0.250 | - | remains |

Packaging & Shipping

1. The aluminum coil will be lined with plastic bags and kraft paper for againsting moisture.

2. The carton paper will be put out of the carton paper.

3. Using fuming strong wooden pallets to load the aluminum coil.

4. Steel belt to fix the aluminum coil steadily on the wooden pallets.

- Q: What are the different methods of joining aluminum sheets?

- Aluminum sheets can be joined using a variety of methods, each with its own benefits and suitability for specific applications. These methods include: 1. Welding: Tungsten Inert Gas (TIG) welding, Metal Inert Gas (MIG) welding, and Resistance Spot Welding (RSW) are all techniques that can be used to join aluminum sheets. TIG welding is commonly chosen for thin sheets due to its precise control and high-quality results. MIG welding, on the other hand, is faster and more suitable for thicker sheets. RSW creates strong welds in a short amount of time by using localized heat and pressure. 2. Adhesive bonding: Adhesive bonding involves using specially designed adhesives for joining aluminum. This method provides excellent strength, even distribution of stress, and corrosion resistance. It is often utilized in applications where aesthetics and weight reduction are important, such as in the automotive and aerospace industries. 3. Mechanical fastening: Mechanical fastening methods, such as riveting and bolting, can also be used to join aluminum sheets. Riveting involves deforming a rivet that passes through pre-drilled holes, while bolting uses screws or bolts. These methods are suitable for temporary or semi-permanent joints and offer easy disassembly if needed. 4. Friction stir welding: Friction stir welding is an innovative method that utilizes a rotating tool to generate frictional heat between the aluminum sheets. This creates a plasticized region that is stirred together to form a solid-state weld. Friction stir welding is particularly useful for large and complex aluminum structures, providing high strength and integrity. 5. Clinching: Clinching is a cold-forming process that joins aluminum sheets without the need for heat or additional materials. It involves pressing the sheets together, creating a mechanical interlock and a strong joint. This method is cost-effective, efficient, and suitable for joining dissimilar metals. 6. Laser welding: Laser welding involves using a high-energy laser beam to melt and fuse the aluminum sheets together. It offers precise control, minimal heat input, and high welding speeds, making it suitable for thin and delicate sheets. Laser welding also provides excellent aesthetics and minimal distortion. The choice of joining method depends on various factors, such as application requirements, material thickness, cost considerations, and desired joint strength. Each method has its own advantages and limitations, and selecting the most appropriate method is crucial to ensure a successful and durable joint.

- Q: Is it possible to substitute traditional wooden windows and doors with aluminum sheets?

- <p>Yes, you can use aluminum sheets to replace traditional wooden windows and doors. Aluminum is a popular choice due to its durability, low maintenance, and resistance to weather and pests. It also offers good thermal performance and can be designed to mimic the appearance of wood. However, it's important to consider factors like insulation, cost, and the specific design requirements of your project before making the switch.</p>

- Q: Are 101 aluminum sheets magnetic?

- Negative, 101 sheets of aluminum lack magnetic properties. Aluminum, being a non-magnetic metal, does not possess the ability to allure or retain magnetic forces.

- Q: How to distinguish fluorocarbon spraying and powder spraying aluminium plate

- 3, powder coating is spraying equipment (electrostatic spray machine) the powder coating is sprayed onto the surface of the workpiece under the electrostatic interaction, the powder will be uniformly adsorbed on the surface of the workpiece, the formation of powder coating; powder coatings after high temperature baking leveling curing, into effect (different effect of different kinds of powder coatings in the final) powder coating; spraying effect on mechanical strength, adhesion, corrosion resistance, aging resistance and superior cost in spray painting process, under the same effect.

- Q: Are aluminum sheets suitable for insulation cladding?

- Aluminum sheets are a suitable option for insulation cladding. This material is highly versatile and durable, commonly used in construction for multiple purposes, including insulation cladding. The thermal properties of aluminum sheets are excellent, effectively preventing heat transfer. Additionally, their low thermal conductivity ensures improved energy efficiency by minimizing heat transfer between the building's interior and exterior. Moreover, aluminum is lightweight and easy to handle, making it convenient for installation purposes. It is also resistant to corrosion, allowing it to withstand various weather conditions and remain a long-lasting choice. Furthermore, aluminum sheets are available in different thicknesses, providing customization options based on specific insulation requirements. Not only do aluminum sheets possess functional benefits, but they also enhance the overall appearance of the building. With their sleek and modern look, these sheets can be easily painted or coated in different colors to match the desired aesthetic design. In conclusion, aluminum sheets are an excellent choice for insulation cladding due to their thermal properties, durability, ease of installation, and aesthetic appeal.

- Q: What are the advantages of using aluminum sheets in the transportation industry?

- There are several advantages of using aluminum sheets in the transportation industry. Firstly, aluminum is a lightweight material, making it ideal for use in vehicles as it helps reduce fuel consumption and increase overall efficiency. This is particularly important for industries such as aviation and automotive, where weight reduction is a key factor in improving performance. Secondly, aluminum has excellent corrosion resistance properties. This is crucial in the transportation industry, where vehicles are exposed to various environmental conditions such as rain, snow, and road salt. Using aluminum sheets helps to extend the lifespan of vehicles and reduces maintenance costs associated with corrosion-related issues. Additionally, aluminum is highly recyclable, making it a more sustainable choice compared to other materials. The transportation industry is increasingly focusing on sustainability, and the use of aluminum sheets aligns with these goals. Recycling aluminum requires significantly less energy compared to producing it from raw materials, leading to reduced carbon emissions and energy consumption. Moreover, aluminum offers excellent formability and versatility. It can be easily molded into various shapes and sizes, allowing manufacturers to design lightweight yet strong structures. This flexibility in design enables the production of more aerodynamic vehicles, leading to improved fuel efficiency. Lastly, aluminum sheets have high strength-to-weight ratio, meaning they can provide the required strength while still being lightweight. This property makes aluminum an ideal material for applications that require strength and durability, such as vehicle bodies, chassis, and structural components. Overall, the advantages of using aluminum sheets in the transportation industry include weight reduction, corrosion resistance, sustainability, formability, versatility, and high strength-to-weight ratio. These benefits contribute to improved performance, fuel efficiency, and durability of vehicles, making aluminum an excellent choice for various transportation applications.

- Q: What is the electrical conductivity of aluminum sheets?

- Aluminum sheets possess a rather high electrical conductivity, positioning aluminum as an exceptional conductor of electricity among typical metals. With an approximate conductivity rating of 37.7 x 10^6 siemens per meter (S/m), aluminum thrives as a favored selection for an array of electrical purposes, including wiring, power transmission lines, and electrical connectors.

- Q: What is the maximum sheet size available for aluminum sheets?

- The maximum sheet size available for aluminum sheets can vary depending on the manufacturer and specific application. However, in general, the standard maximum sheet size for aluminum sheets is typically 4 feet by 12 feet (48 inches by 144 inches). This size is commonly used in various industries such as construction, automotive, and aerospace. It is important to note that larger sizes may be available upon request from certain suppliers, but these may come with additional costs and considerations.

- Q: What are the different methods for engraving aluminum sheets?

- There are several different methods for engraving aluminum sheets, each with its own advantages and applications. 1. Laser engraving: This is one of the most popular methods for engraving aluminum sheets. It uses a laser beam to vaporize the aluminum surface, creating a permanent and precise engraving. Laser engraving offers high precision, speed, and versatility, making it suitable for a wide range of applications. 2. Mechanical engraving: This method involves using a mechanical tool, such as a rotary cutter or diamond-tipped tool, to physically remove material from the aluminum surface. Mechanical engraving can achieve deep and detailed engravings, making it suitable for applications where durability and depth are important. 3. Chemical etching: Chemical etching involves using chemicals to selectively remove material from the aluminum surface. It is a highly precise method that can create intricate and detailed designs. Chemical etching is often used in industries such as electronics and aerospace, where precision and high-quality finishes are required. 4. CNC milling: Computer Numerical Control (CNC) milling is a method that uses a computer-controlled machine to remove material from the aluminum sheet. It can achieve precise and complex engravings, making it suitable for applications that require intricate designs or 3D engravings. 5. Hand engraving: Hand engraving involves using handheld tools, such as gravers or chisels, to manually create engravings on the aluminum surface. While it may not offer the same level of precision as other methods, hand engraving allows for artistic freedom and customization. Each method has its own advantages and limitations, so the choice of engraving method depends on factors such as the desired design, level of detail, production volume, and budget.

- Q: What is the difference between the alloy 1060H24 aluminum plate and the alloy 1100H24 aluminum plate?

- The difference between the two is very small, 1060 and 1100 are 1 pure aluminum plate, H24 aluminum sheet, that is, the degree of hardness!Specific differences are as follows:Series: 1000 series aluminum alloy represents the 1050, 1060 and 1100 series.

Send your message to us

Sheets of Swirl Brushed Aluminum Coil and Sheet 1050 1100 3003 H14 H24 O

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords