Sheets of Aluminum Foil - Aluminum Sheet Construction T3 5083 0.05mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.2~320mm |

Width | <2800mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Payment | L/C ,T/T |

Brief Introduction for Cold Rolled Steel Coil

Cold Rolled Steel Coil is steel that has been worked below its recrystallization temperature by passing it between a pair of rollers. Recrystallization temperature is the temperature at which grains in the lattice structure of the metal have been rearranged, leaving it free of strain and deformations. Cold Rolled Steel Coil is pre-treated before being cold rolled with a process known as pickling, which uses strong acids to remove scale and other impurities. The Cold Rolled Steel Coil is then passed through rollers to reduce its thickness. Most cold rolling takes place in multiple passes and as the size of the Cold Rolled Steel Coil is further reduced, its strength and hardness both increase, but its ductility decreases. After cold rolling, heating the metal up in a process known as annealing can restore some of its ductility. The final Cold Rolled Steel Coil may be manufactured in the form of sheets, strips, bars, or other forms.

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

Our Services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3. We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

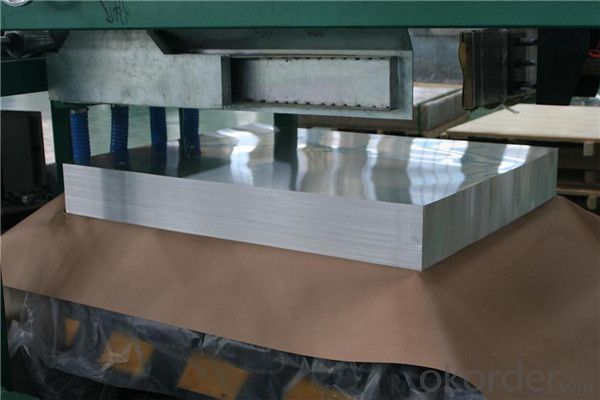

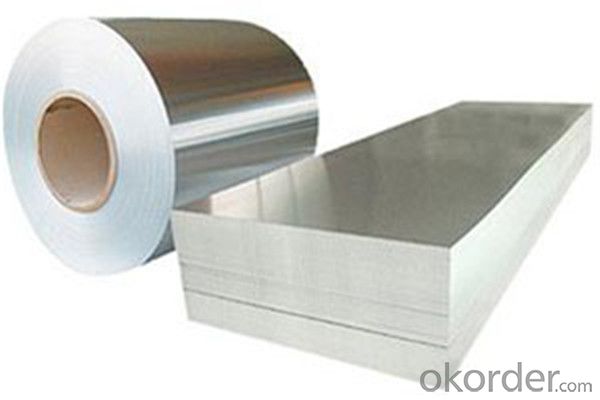

Photos of products

- Q: What is the typical modulus of elasticity for aluminum sheets?

- The typical modulus of elasticity for aluminum sheets is around 70 GPa (gigapascals) or 10 million psi (pounds per square inch). However, it is important to note that the modulus of elasticity can vary depending on the specific alloy and temper of the aluminum sheet.

- Q: How does the surface roughness affect the adhesion of coatings on aluminum sheet?

- Surface roughness plays a crucial role in the adhesion of coatings on aluminum sheet. The level of roughness on the surface of the sheet directly impacts the mechanical interlocking between the coating and the substrate, which is essential for strong adhesion. When the surface of the aluminum sheet is smooth, there is limited contact area between the coating and the substrate, resulting in weak adhesion. On the other hand, a rough surface provides more contact points, increasing the interlocking between the coating and the aluminum sheet, leading to improved adhesion strength. Additionally, a rough surface promotes better wetting of the coating material on the aluminum sheet. This means that the coating material can spread more easily over the surface, filling in any gaps or crevices, and creating a more uniform and continuous coating. This improved wetting contributes to enhanced adhesion. Furthermore, a rough surface can also increase the overall surface area of the aluminum sheet. A larger surface area means that there is more available space for the coating material to adhere to, increasing the adhesion strength. It is important to note that there is an optimum level of roughness for achieving the best adhesion. If the surface is excessively rough, it may lead to incomplete coverage of the coating material or the formation of voids, reducing adhesion. Therefore, finding the right balance of roughness is crucial to ensure optimal adhesion of coatings on aluminum sheet.

- Q: im making a presentation and once i read through it it feels like its leading up to something but then goes flat. any ideas. my project ' steel cars compared to aluminium'

- Aluminium is extremely flammable. We use it in thermite welding and as solid rocket fuel. The Emperor Napoleon carried* an aluminium fork while the lower royalty had to make do with gold forks. *In those days people carried their table wear around with them same as we carry our car keys.

- Q: What are aluminum sheets made of?

- Aluminum sheets are typically made of pure aluminum or aluminum alloy, which is a combination of aluminum and other elements such as copper, magnesium, or zinc. The exact composition of the alloy depends on the specific application and desired properties of the sheet. Pure aluminum sheets are softer and more malleable, while alloyed aluminum sheets offer increased strength, durability, and resistance to corrosion. The sheets are produced through a process called rolling, where a large block or ingot of aluminum is passed through a series of rollers to reduce its thickness and create the desired sheet size.

- Q: What are the potential environmental issues that arise from the use of aluminum sheets?

- <p>Yes, there are environmental concerns related to using aluminum sheets. The production process is energy-intensive and contributes to greenhouse gas emissions. Additionally, the mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. The disposal of aluminum waste can also lead to pollution if not properly managed. However, aluminum is highly recyclable, which can mitigate some of these concerns if recycling practices are adopted widely.</p>

- Q: Can 101 aluminum sheets be bonded to other materials?

- Yes, 101 aluminum sheets can be bonded to other materials. Aluminum can be bonded using various methods such as adhesive bonding, welding, or mechanical fastening techniques. The choice of bonding method depends on the specific materials being bonded and the desired strength and durability of the bond.

- Q: Is it possible to use aluminum sheets for indoor purposes?

- <p>Yes, aluminum sheets can be used for indoor applications. They are commonly used in interior design for their durability, lightweight, and resistance to corrosion. Aluminum sheets are often utilized in the construction of furniture, decorative panels, and even as a material for interior walls and ceilings. Their ease of maintenance and ability to be recycled make them an environmentally friendly option for indoor use.</p>

- Q: Can aluminum sheets be used for sign making?

- Sign making can indeed utilize aluminum sheets. The sign making industry favors aluminum for its resilience, lightweight properties, and ability to resist corrosion. It can be effortlessly cut and molded into different dimensions and styles, granting it versatility across various sign types. Moreover, aluminum sheets can undergo painting or coating with vinyl graphics to increase their visual allure, enhancing their ability to attract attention. Ultimately, aluminum sheets present a dependable and economical choice for crafting signs that are both durable and of superior quality.

- Q: How do you achieve a mirror-like finish on aluminum sheets?

- To achieve a mirror-like finish on aluminum sheets, a multi-step process is usually followed. First, the sheets are thoroughly cleaned and degreased to remove any dirt or oils. Then, they are sanded with progressively finer grits of sandpaper to smooth out any imperfections. Next, a polishing compound is applied and buffed onto the surface using a rotating wheel or by hand. This step is repeated with finer and finer compounds until the desired level of shine is achieved. Finally, a protective coating might be applied to maintain the mirror-like finish.

- Q: Are aluminum sheets suitable for lightweight structures?

- Indeed, aluminum sheets prove to be a fitting choice when it comes to lightweight structures. Renowned for its low density and impressive strength-to-weight ratio, aluminum emerges as an optimal material for applications requiring reduced weight. Industries such as aerospace, automotive, and construction frequently rely on aluminum sheets due to their exceptional corrosion resistance, durability, and malleability. These properties facilitate effortless fabrication and installation. Moreover, the versatility of aluminum sheets extends to their effortless joining through diverse welding and adhesive methods, thereby bolstering their aptness for lightweight structures.

Send your message to us

Sheets of Aluminum Foil - Aluminum Sheet Construction T3 5083 0.05mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords