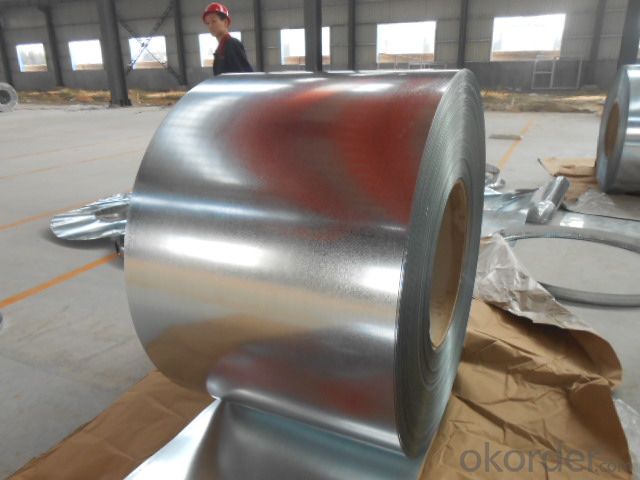

SGCH 0.12*750mm Hot Dip Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

competitive price galvanized steel coils

specification

Certificate | ISO9001:2008 |

Standard | ASTM A653,JIS G3302 SGCC/SGCH ,GB/T 2518, European standard |

Grade | SGCC, SGCH, SGCD1-SGCD3, SGC340-SGC570, SGCC, DX51D |

Type | Steel Coil |

Technique | Cold Rolled |

Oil | Chromate,Light oiled or Unoiled |

Surface Treatment | Galvanized |

Special Use | High-strength Steel Plate |

Thickness | 0.16mm-1.2mm |

Width | 1250mm or under |

Length | coil |

Spangle | Big,Regular,Small,Zero |

Al-Zn coating | 40-275g/m2 |

Hardness | 55-90HRB |

Coil inner diameter | 508 or 610mm |

Coil weight | 6-8 tons |

Coil OD | Max 1500mm |

Specification | (0.12-1.20)*1250mm or under |

Terms of payment | T/T or L/C |

Place of Origin | Shandong, China (Mainland) |

Port | Qingdao, Xingang, China |

Shipment | shipped by 20 feet container, loading about 25 tons |

Package | seaworthy standard export package |

MOQ | 15 Metric Ton/Metric Tons |

Supply Ability | 20000 Metric Ton/Metric Tons per Month |

- Q: How are steel coils processed for slitting or edge trimming?

- Steel coils are processed for slitting or edge trimming by feeding the coil into a slitting or trimming machine. The machine uses sharp rotating blades to cut the coil into smaller strips or remove the excess material from the edges. This process helps to create narrower coils or achieve precise edge dimensions for various applications.

- Q: I have never owned a non-stainless steel chef's knife and have been looking at some to buy recently, but all of them have various degrees of wear and use. They say that the wear is normal for non-stainless steel knives, but how can I tell if it is too much wear, or if the blade is clean?

- cold rolled steel waers as you carve meat. If the blad if to thin you may want a better one. Utica knife in utica N.Y. made them up to about 10 years ago and i still buy them at auctions.

- Q: where can i find information online about steel residential homes that use solar energy?

- Sun energy technologies is not as commonplace as it's photovoltaic cousin, but is nevertheless an important piece in the actual sun power bigger picture. Solar thermal uses solar power in order to heat either drinking water or even atmosphere, that is after that transferred via collectors within order to it's location. With all the actual challenges we're dealing with in respect within order to global warming and also the stunning increase in air pollution caused by green house gas, solar energy as well as also the techniques utilized to funnel it have become vitally important to our long term which of our planet.

- Q: What are the different types of steel coil surface finishes for aesthetics?

- There are several types of steel coil surface finishes commonly used for aesthetic purposes. These include mill finish, brushed finish, mirror finish, embossed finish, and patterned finish. Each finish has its own unique appearance and texture, allowing for a wide range of aesthetic options when it comes to steel coil applications.

- Q: How are steel coils used in the production of electrical systems?

- Steel coils are used in the production of electrical systems as they serve as the core component of transformers and inductors. They provide a magnetic field necessary for the efficient functioning and transformation of electrical energy.

- Q: How do steel coils contribute to sustainability in construction?

- Several factors contribute to the sustainability of construction when it comes to steel coils. To begin with, steel is an incredibly durable material with a long lifespan. Its use in the construction of structural components like beams, columns, and frames ensures the stability and strength of buildings. This durability translates to reduced maintenance requirements and a longer service life for structures. As a result, the need for frequent repairs or replacements is diminished, leading to a decrease in the overall environmental impact associated with material waste and energy consumption. Moreover, steel is highly recyclable. Steel coils can be easily recycled and reused in new construction projects. The recycling process for steel has a significantly lower environmental impact compared to the production of new steel. By incorporating recycled steel coils into construction projects, the demand for new steel production is reduced, resulting in lower greenhouse gas emissions and a smaller carbon footprint. This approach helps conserve natural resources, reduces the extraction of raw materials, and minimizes energy consumption in steel production. Additionally, steel is an ideal material for off-site prefabrication. This means that steel coils can be manufactured in controlled environments in factories, minimizing construction waste and improving construction efficiency. Prefabricating steel coils reduces on-site material waste and decreases the need for transportation of construction materials. Consequently, this reduces air pollution and energy consumption during construction. Furthermore, steel's high strength-to-weight ratio allows for lighter and more efficient structures. By using steel coils, construction projects can optimize material usage, resulting in reduced material consumption and lessening the overall environmental impact. The lightweight nature of steel coils also facilitates easier transportation, reducing fuel consumption and associated emissions during delivery. In summary, steel coils contribute to the sustainability of construction through their durability, recyclability, prefabrication capabilities, and high strength-to-weight ratio. By utilizing steel coils, construction projects can minimize waste, conserve resources, reduce energy consumption, and decrease the environmental impact, ultimately promoting a more sustainable built environment.

- Q: How are steel coils tested for strength and durability?

- Steel coils are tested for strength and durability through various methods such as tensile testing, impact testing, and fatigue testing. Tensile testing involves subjecting the steel coil to tension until it breaks, measuring the maximum force it can withstand. Impact testing involves striking the coil with a heavy object to assess its ability to resist sudden shocks. Fatigue testing involves subjecting the coil to repeated load cycles to determine its resistance to long-term stress. These tests help ensure that steel coils meet the required strength and durability standards.

- Q: What are the potential dangers of handling steel coils?

- There are numerous hazards that come with handling steel coils. To begin with, improper handling of steel coils can result in physical injuries. If not handled correctly, the weight of the coils can cause strains, sprains, or even more severe injuries. This is particularly true when using manual lifting equipment or when attempting to move the coils without proper training or assistance. Moreover, steel coils often have sharp edges or protruding parts that can lead to cuts or puncture wounds if not handled with caution. These sharp edges can be especially dangerous when manipulating or positioning the coils during transportation or storage. It is vital to wear suitable personal protective equipment, such as gloves, to minimize the risk of injury. Additionally, steel coils can become unstable if not adequately secured or balanced. Poor stacking or storage practices can result in the coils shifting or falling, potentially causing serious harm or damage. It is imperative to adhere to proper stacking and storage procedures, including the use of appropriate equipment and supports, to ensure stability and prevent accidents. Furthermore, steel coils are often stored in areas with limited space or uneven surfaces, increasing the risk of trips, falls, or collisions. It is essential to maintain clear and well-organized storage areas, free of obstacles or hazards, to reduce the likelihood of accidents. Lastly, steel coils can be susceptible to corrosion or rust, which can weaken the metal and compromise their structural integrity. This can heighten the risk of the coils collapsing or breaking during handling, potentially causing injuries or property damage. Regular inspections and maintenance of the coils, as well as proper storage in dry and well-ventilated areas, can help mitigate this risk. Overall, the potential dangers associated with handling steel coils encompass physical injuries from their weight and sharp edges, instability during transportation or storage, accidents due to limited space or uneven surfaces, and the risk of structural failure due to corrosion or rust. It is crucial to adhere to proper safety protocols, receive adequate training, and utilize the necessary equipment to minimize these risks and ensure the safe handling of steel coils.

- Q: What are the common surface treatments for galvanized steel coils?

- The common surface treatments for galvanized steel coils include passivation, chromate coating, and oiling. Passivation is a process where a thin layer of protective material, such as zinc phosphate or chromate, is applied onto the galvanized steel surface. This layer helps to enhance the corrosion resistance of the steel by providing a barrier against moisture and atmospheric elements. Passivation also improves the adhesion of subsequent coatings or paints that may be applied to the steel. Chromate coating, also known as chromating or chromate conversion coating, involves the application of a thin layer of chromate onto the galvanized steel surface. This coating provides an additional layer of protection against corrosion and improves the appearance of the steel. Chromate coatings can be clear or colored, depending on the desired aesthetic. Oiling is another common surface treatment for galvanized steel coils. This involves the application of a thin layer of oil onto the surface of the steel, which helps to prevent the formation of rust and corrosion during storage and transportation. Oiling also provides temporary protection against moisture and other environmental factors until the steel is further processed or used in its final application. These surface treatments are commonly used to enhance the performance, durability, and appearance of galvanized steel coils, ensuring that they can withstand harsh conditions and maintain their quality over time.

- Q: I am refinishing a table and on my can of polyurethane, it indicates not to sand with steel wool prior to application. Why is that?

- Steel wool will leave invisible pieces of metal embedded in the finish, no matter how much you try to wipe it off. When you cover it with the polyurethane, it is trapped and turns dark over time, ruining the look of the table. Yeh, so follow the directions exactly for the best finish. Good luck!! : /

Send your message to us

SGCH 0.12*750mm Hot Dip Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords