Self-Adhesive Fiberglass Mesh Fabric - High Quality Warp Knitting Polyester Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

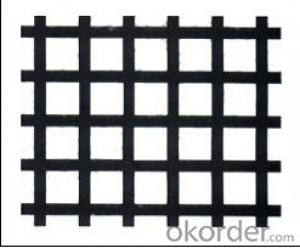

Warp Knitting Polyester geogrid

The Warp Knitting Polyester geogrid selects the excel in synthetic fiber as a raw material,uses the warp knitting oriented structure,latitude and longitude in the fabric to the yarn between not curving condition,the intersection unifies mutually with the excel in textile fiber filament bundle,forms the reliable combining site,displays its mechanical properties fully.

Product Function

2.Characteristics

1. Each kind of higher Uygur path,railroad’s soft roadbed enhancement isolation different base earth material.

2. The river bank,the slope of embankment strengthen stably.

3. Each kind of ground strengthens stably.

4. Strengthens the bridge connection surface.

3.Application

1. Geogrid width ranging from 1000mm to 6000mm

2. High intensity, high module, low slow change ,anti-aging , anti-embrittlement, tensile strength to be high strength.

3. High anti-peel strength ,with the soil crushed stone binding force strong and may pre-design many kinds of characteristics.

4.FAQ

Product No. | Stretching ratio(%) | Grid(mm) | Width(mm) | ||

Vertical | Horizontal | ||||

PET20-20 | 13 | 20 | 20 | 12.7x12.7 25.4x25.4 | ±5 |

PET30-30 | 13 | 30 | 30 | 12.7x12.7 25.4x25.4 | ±5 |

PET40-40 | 13 | 40 | 40 | 12.7x12.7 25.4x25.4 | ±5 |

PET50-50 | 13 | 50 | 50 | 12.7x12.7 25.4x25.4 | ±5 |

PET80-80 | 13 | 80 | 80 | 12.7x12.7 25.4x25.4 | ±5 |

PET100-100 | 13 | 100 | 100 | 12.7x12.7 25.4x25.4 | ±5 |

PET120-120 | 13 | 120 | 120 | 12.7x12.7 25.4x25.4 | ±5 |

Note: The Warp Knitting Polyestergeogrid are available with a width range of 1000mm~6000mm.Other specifications are also available on customer request.

- Q: Construction method of organosilicon waterproof coating

- Basic level treatment: the surface of the base layer is required to be smooth, and uneven sand lifting is not allowed.

- Q: How is fiberglass fabric used in the production of fire-resistant blankets?

- Due to its exceptional fire-resistant properties, fiberglass fabric plays a crucial role in the production of fire-resistant blankets. This fabric is made from woven glass fibers, which possess high resistance to heat and flames. To enhance its fire-resistant capabilities, fiberglass fabric is initially coated with a fire-resistant material or treated with a fire-retardant chemical during the production process. This treatment ensures that the fabric can withstand high temperatures and prevent the spread of fire. By layering multiple sheets of fiberglass fabric together, thick and durable fire-resistant blankets are manufactured. These blankets are sewn or bonded together to create a single unit, offering maximum protection. When exposed to fire, fiberglass fabric acts as an insulator, reflecting heat and preventing its transfer to the other side of the blanket. This effectively suppresses the spread of flames and reduces the risks of burns and injuries. Moreover, fiberglass fabric is lightweight and flexible, allowing for easy handling and maneuverability during emergency situations. Consequently, fire-resistant blankets made with fiberglass fabric find wide application in industries such as firefighting, oil and gas, manufacturing, and construction. They serve to safeguard workers, equipment, and valuable assets from fire hazards. Overall, the utilization of fiberglass fabric in the production of fire-resistant blankets ensures a high level of protection against heat and flames, effectively mitigating fire-related risks.

- Q: Is fiberglass fabric resistant to tearing or ripping?

- Yes, fiberglass fabric is highly resistant to tearing or ripping due to its strong and durable nature.

- Q: What are the standard widths of fiberglass fabric?

- The standard widths of fiberglass fabric can vary depending on the manufacturer and intended use. However, in general, fiberglass fabric is commonly available in widths ranging from 1 inch to 60 inches. Some manufacturers may offer wider widths up to 120 inches or more. The choice of width depends on the specific application and project requirements. For smaller projects or more intricate details, narrower widths are often preferred, while wider widths are suitable for larger-scale applications. It is important to check with the manufacturer or supplier to confirm the available widths and select the most appropriate option for your specific needs.

- Q: Can fiberglass fabric be used for making insulation boards or panels?

- Yes, fiberglass fabric can be used for making insulation boards or panels.

- Q: Can fiberglass fabric be used for making gaskets or seals?

- Yes, fiberglass fabric can be used for making gaskets or seals. Its high strength and heat resistance make it a suitable material for applications that require a tight seal, such as in automotive, aerospace, or industrial environments. Additionally, fiberglass fabric can be easily molded or cut to desired shapes, making it a versatile option for gasket and seal manufacturing.

- Q: What is the material of the computer mainboard PCB?

- On the circuit board, there is a patchwork of circuit wiring; and then the above is the edges and corners of each component: slot, chip, resistors, capacitors and so on. When the host is powered on, the current will pass through the CPU, the north and South Bridge chip, memory slot, AGP slot, PCI slot, IDE interface, and the serial port, parallel port and PS/2 interface of the main board edge. Subsequently, the motherboard will identify the hardware according to the BIOS (basic input and output system), and enter the operating system to play the function of supporting the system platform.

- Q: How does fiberglass fabric perform in abrasive environments?

- Fiberglass fabric performs exceptionally well in abrasive environments due to its high strength, durability, and resistance to wear and tear. The fabric's unique composition of glass fibers provides excellent resistance against abrasion, ensuring its longevity and performance even in harsh conditions.

- Q: Can fiberglass fabric be used for insulation in telecommunications cables?

- Yes, fiberglass fabric can be used for insulation in telecommunications cables. Fiberglass fabric has excellent thermal insulation properties, making it an ideal choice for insulating cables that carry electrical signals. It can withstand high temperatures and is resistant to fire, chemicals, and abrasion, providing a reliable and durable insulation solution for telecommunications cables. Additionally, fiberglass fabric is lightweight, flexible, and easy to handle, making it convenient for cable installation and maintenance. Its high dielectric strength also ensures that it does not interfere with the electrical signals transmitted through the cables. Therefore, fiberglass fabric is commonly used as an insulation material in telecommunications cables to protect the cables and ensure efficient and reliable signal transmission.

- Q: Does fiberglass fabric shrink?

- Yes, fiberglass fabric can shrink under certain conditions. Fiberglass fabric is made from woven or knitted glass fibers which are coated with a resin or silicone finish. While the glass fibers themselves do not shrink, the coating on the fabric can undergo some shrinkage when exposed to heat or other factors. When fiberglass fabric is subjected to high temperatures, such as during the manufacturing process or when exposed to excessive heat, the resin or silicone coating can melt or shrink. This can cause the fabric to contract and become smaller in size. Additionally, if the fabric is not properly cured or dried after being coated, it can also shrink. It is important to note that the amount of shrinkage in fiberglass fabric can vary depending on the specific type of coating used, the manufacturing process, and the conditions it is exposed to. Therefore, it is advisable to carefully follow the manufacturer's instructions and guidelines to prevent any potential shrinkage. In conclusion, while the glass fibers in fiberglass fabric do not shrink, the coating on the fabric can undergo some shrinkage when exposed to heat or other factors.

Send your message to us

Self-Adhesive Fiberglass Mesh Fabric - High Quality Warp Knitting Polyester Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords