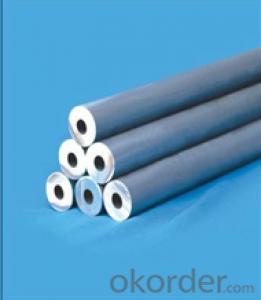

Seamless HARD Carbon Steel Pipe&Tube For Tunnel And Anchor Rod Q345 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1 - 14 mm | Section Shape: | Round | Outer Diameter: | 8 - 80 mm |

| Place of Origin: | HEB,HEB,HEB,China,FORM A,FORM E China (Mainland) Ch China (Mainland) | Secondary Or Not: | Non-secondary | Application: | Hydraulic Pipe |

| Technique: | Cold Rolled | Certification: | ISO9001:2008 | Surface Treatment: | oil |

| Special Pipe: | Thick Wall Pipe | Alloy Or Not: | Is Alloy | length: | 5-8m |

| usage3: | machine bush parts | usage4: | machine and engine pin | usage5: | tunnel and anchor rod |

| Test: | eddy current test,Ultrasonic Testing | usage2: | shock absorption bush | usage1: | power transmission machinery |

| colour: | black | name: | large-diameter hot-expanding seamless steel pipe | Grade: | 10#,20#,45#,16Mn,16Mo,16mo3,Q345,ST35,St37,ST37.4,St52,10#-45#,Mo,Q195-Q345,ST35-ST52 |

| Standard: | ANSI A210-1996,ASTM A1020-2002,ASTM A213-2001,ASTM A403-2007,ASTM A789-2001,BS 1387,BS EN10296,DIN 17175,DIN EN 10025,DIN EN 10217-1-2005,GB/T8162,GB/T8163,JIS G3459-2004,JIS G3461-2005,ASTM,BS,DIN,GB,JIS |

Packaging & Delivery

| Packaging Detail: | Marking: as per customer's requests. Painting varnish coating on the pipe. steel trips, woven bag |

| Delivery Detail: | 10-45 days or as the customer's request |

Seamless Carbon Hard Steel Pipe&Tube For Tunnel And Anchor Rod

Type | Manufacture & Sales OEM | |

Process | Seamless, Cold drawn and Cold rolled, finish-rolled | |

Material | 20#, 10#, 45#, 35# , Q345, 16Mn, 42CrMo | |

size | Outer Diameter | 8 –80mm |

Wall Thickness | 1-14mm | |

Length | 5-10m | |

Standard

| DIN st42, st45, st35, st37 and st52, GB 8162 | |

Package | 1. Bundle packing. 2. Bevelled end or plain end or warnished as per buyer's requestments. 3. Marking: as per customer's requests. 4. Painting varnish coating on the pipe. 5. Plastic caps at ends. | |

Delivery Time | 15to20 days or as clients reqestments | |

- Q: Can steel pipes be used for steam distribution?

- Yes, steel pipes can be used for steam distribution. Steel pipes are known for their high strength and durability, making them suitable for carrying steam at high temperatures and pressures. Additionally, steel pipes have excellent thermal conductivity, allowing for efficient heat transfer during steam distribution.

- Q: What is the difference between internal and external coating of steel pipes?

- The main difference between internal and external coating of steel pipes is their purpose and the materials used. The internal coating is applied to the inside surface of the pipe to protect it from corrosion, erosion, and chemical reactions with the transported fluids. It is typically made of materials such as epoxy or polyethylene. On the other hand, the external coating is applied to the outside surface of the pipe to provide protection against atmospheric corrosion, soil corrosion, and mechanical damage. External coatings are usually made of materials like fusion-bonded epoxy, polyethylene, or polypropylene.

- Q: What is the difference between internal coating and external lining of steel pipes?

- Internal coating and external lining are two different methods used to protect steel pipes from corrosion and other forms of damage. Internal coating refers to the process of applying a protective layer or coating to the inner surface of the steel pipe. This is done to prevent the pipe from corroding or being damaged by the fluid or substance being transported through it. The coating is typically made of materials such as epoxy, polyurethane, or polyethylene, which provide a barrier between the pipe and the transported material. Internal coating helps to extend the lifespan of the pipe and maintain the quality of the transported material. On the other hand, external lining refers to the process of applying a protective layer or lining to the outer surface of the steel pipe. This is done to protect the pipe from external factors such as soil, moisture, chemicals, or physical damage. The external lining is usually made of materials such as polyethylene, polypropylene, or fusion-bonded epoxy. The lining acts as a barrier, preventing corrosive substances from coming into contact with the pipe and causing damage. It also helps to maintain the structural integrity of the pipe and prevent any leaks or cracks from forming. In summary, the main difference between internal coating and external lining of steel pipes is the location of the protective layer. Internal coating is applied to the inner surface of the pipe, while external lining is applied to the outer surface. Both methods aim to protect the pipe from corrosion and damage, but they focus on different aspects of pipe protection.

- Q: Are steel pipes resistant to UV radiation?

- No, steel pipes are not inherently resistant to UV radiation. They can be affected by prolonged exposure to UV rays, leading to degradation and potential damage over time.

- Q: Is there any difference between thermal expansion seamless steel pipe and seamless steel pipe?

- One is thermal expansion on a bar, that is, piercing between the bars and expanding the tube with a little bit of mandrel. The other is to expand the formed tube before it is heated so that the defects in the pipe will be enlarged. Comparatively speaking, the quality of the first kind is better than the second, and you should belong to the second kind. Compared with the original seamless seamless tube, the quality and chemical properties are certainly different. The price will be cheaper, too.

- Q: Can steel pipes be used for wastewater treatment plants?

- Yes, steel pipes can be used for wastewater treatment plants. Steel pipes are commonly used in wastewater treatment plants due to their durability, strength, and resistance to corrosion. They are able to withstand the harsh conditions and chemicals present in wastewater treatment processes, making them a suitable choice for transporting and distributing wastewater within the plant.

- Q: What are the potential health hazards associated with steel pipe installation?

- Some potential health hazards associated with steel pipe installation include exposure to hazardous chemicals used in the coating or treatment of the pipes, inhalation of dust or fumes generated during cutting or welding, and physical injuries due to accidents or mishandling of heavy equipment. Additionally, improper handling or disposal of waste materials and contaminated water can pose environmental health risks. It is important to follow proper safety protocols, use personal protective equipment, and ensure proper ventilation and waste management to mitigate these hazards.

- Q: How are steel pipes classified according to their use?

- Steel pipes can be classified according to their use into various categories such as structural pipes, plumbing pipes, oil and gas pipes, and industrial pipes.

- Q: Can steel pipes be used for oil transportation?

- Yes, steel pipes can be used for oil transportation. Steel pipes are commonly used in the oil and gas industry for the transportation of crude oil, petroleum products, and natural gas. They are preferred due to their strength, durability, and resistance to corrosion. Steel pipes are capable of withstanding high-pressure environments and can be used for both onshore and offshore oil transportation. Additionally, steel pipes can be welded together to form long pipelines, making them a cost-effective solution for transporting oil over long distances. Overall, steel pipes are a reliable and efficient choice for oil transportation.

- Q: Is it good to buy a simple wardrobe or a steel pipe?

- If the home place is big, buy Wooden, good-looking durable, if the place is small, buy cloth, easy to receive, mobile, tidy and cheap.

Send your message to us

Seamless HARD Carbon Steel Pipe&Tube For Tunnel And Anchor Rod Q345 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords