Seamless HARD Carbon Steel Pipe&Tube For Tunnel And Anchor Rod 20# CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1 - 14 mm | Section Shape: | Round | Outer Diameter: | 8 - 80 mm |

| Place of Origin: | HEB,HEB,HEB,China,FORM A,FORM E China (Mainland) Ch China (Mainland) | Secondary Or Not: | Non-secondary | Application: | Hydraulic Pipe |

| Technique: | Cold Rolled | Certification: | ISO9001:2008 | Surface Treatment: | oil |

| Special Pipe: | Thick Wall Pipe | Alloy Or Not: | Is Alloy | length: | 5-8m |

| usage3: | machine bush parts | usage4: | machine and engine pin | usage5: | tunnel and anchor rod |

| Test: | eddy current test,Ultrasonic Testing | usage2: | shock absorption bush | usage1: | power transmission machinery |

| colour: | black | name: | large-diameter hot-expanding seamless steel pipe | Grade: | 10#,20#,45#,16Mn,16Mo,16mo3,Q345,ST35,St37,ST37.4,St52,10#-45#,Mo,Q195-Q345,ST35-ST52 |

| Standard: | ANSI A210-1996,ASTM A1020-2002,ASTM A213-2001,ASTM A403-2007,ASTM A789-2001,BS 1387,BS EN10296,DIN 17175,DIN EN 10025,DIN EN 10217-1-2005,GB/T8162,GB/T8163,JIS G3459-2004,JIS G3461-2005,ASTM,BS,DIN,GB,JIS |

Packaging & Delivery

| Packaging Detail: | Marking: as per customer's requests. Painting varnish coating on the pipe. steel trips, woven bag |

| Delivery Detail: | 10-45 days or as the customer's request |

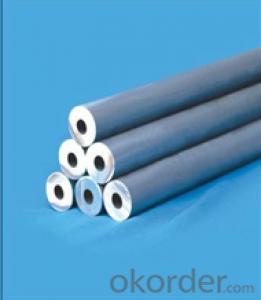

Seamless Carbon Hard Steel Pipe&Tube For Tunnel And Anchor Rod

Type | Manufacture & Sales OEM | |

Process | Seamless, Cold drawn and Cold rolled, finish-rolled | |

Material | 20#, 10#, 45#, 35# , Q345, 16Mn, 42CrMo | |

size | Outer Diameter | 8 –80mm |

Wall Thickness | 1-14mm | |

Length | 5-10m | |

Standard

| DIN st42, st45, st35, st37 and st52, GB 8162 | |

Package | 1. Bundle packing. 2. Bevelled end or plain end or warnished as per buyer's requestments. 3. Marking: as per customer's requests. 4. Painting varnish coating on the pipe. 5. Plastic caps at ends. | |

Delivery Time | 15to20 days or as clients reqestments | |

- Q: Can steel pipes be used for airport construction?

- Yes, steel pipes can be used for airport construction. Steel pipes are commonly used in various construction projects due to their durability, strength, and resistance to corrosion. They are capable of withstanding heavy loads and are often used for underground drainage systems, water supply networks, and structural support in airport construction.

- Q: When can I use the PVC pipe and when to use the galvanized pipe?

- PVC pipeline use temperature is -5 to 90 degrees or so, according to the current market price of around 6000 yuan per ton, the price is cheap. Its corrosion resistance is good, can resist most of the acid and alkali, and unlike the steel pipe that is easy to rust, so in the construction of the upper and lower water pipes and other fields have gradually replaced the trend of steel pipe.

- Q: What are the different methods of pipe insulation for steel pipes?

- There are several methods of pipe insulation for steel pipes, each with its own advantages and suitability for specific applications. Some of the commonly used methods include: 1. Fiberglass insulation: This is one of the most popular methods of pipe insulation. Fiberglass insulation is made of fine glass fibers and is available in various forms such as rolls, sheets, or pre-formed sections. It is lightweight, easy to install, and provides excellent thermal insulation properties. 2. Foam insulation: Foam insulation is another effective method for insulating steel pipes. It is available in different forms, including rigid foam boards or spray foam. Foam insulation is known for its high insulating value and its ability to seal gaps and cracks, providing enhanced energy efficiency. 3. Rubber insulation: Rubber insulation, commonly known as elastomeric insulation, is widely used for insulating steel pipes in HVAC systems. It is flexible, durable, and resistant to moisture, making it suitable for both indoor and outdoor applications. Rubber insulation also offers good thermal and acoustic insulation properties. 4. Polyethylene insulation: Polyethylene insulation is a cost-effective option for insulating steel pipes. It is available in different forms, such as foam tubes or molded sections, and is easy to install. Polyethylene insulation provides good thermal insulation, protects against condensation, and is resistant to water vapor diffusion. 5. Cellular glass insulation: Cellular glass insulation is a rigid insulation material made from crushed glass and a foaming agent. It is known for its exceptional thermal insulation properties, as well as its resistance to moisture, fire, and chemicals. Cellular glass insulation is commonly used in cryogenic and high-temperature applications. It is important to consider factors such as temperature, moisture conditions, and the specific requirements of the project when selecting the appropriate method of pipe insulation for steel pipes. Consulting with a professional or an insulation expert can help determine the best insulation method based on the specific needs and conditions of the project.

- Q: What are the different threading options for steel pipes?

- The different threading options for steel pipes include tapered thread, straight thread, and multiple thread options. Tapered threads are commonly used for pipes that carry fluids or gases under pressure, as they provide a tight seal. Straight threads are used for pipes that require a secure connection but do not need to be sealed tightly. Multiple thread options, such as double and triple threads, are used for high-pressure applications where a stronger connection is needed.

- Q: What are the different methods of cleaning steel pipes?

- There are several methods of cleaning steel pipes, including mechanical cleaning, chemical cleaning, and high-pressure water jetting. Mechanical cleaning involves using wire brushes, scrapers, or sandpaper to physically remove debris and rust from the pipe's surface. Chemical cleaning involves using solvents or acids to dissolve contaminants and rust, followed by flushing the pipe with water. High-pressure water jetting uses a stream of water at high pressure to remove dirt, rust, and other deposits from the pipe's interior and exterior surfaces.

- Q: How are steel pipes used in data centers?

- Steel pipes are commonly used in data centers for various purposes such as routing cables, running water cooling systems, and providing structural support for equipment. They are used to create a robust and organized network infrastructure, ensuring efficient and reliable data transmission and management within the facility.

- Q: What are the different types of steel pipe supports for high-temperature applications?

- Some different types of steel pipe supports for high-temperature applications include hangers, clamps, brackets, and anchors. These supports are designed to withstand the elevated temperatures and provide stability and proper alignment to the piping system.

- Q: 20# seamless steel pipe and seamless steel pipe 20G what is the difference?

- 20G seamless steel tube is a high-pressure boiler tube. In addition to carbon content, 20G seamless steel tubes also have some trace elements that are more suitable for use as boiler pressure vessels. In addition, 20G also focuses on its physical performance. Such as bending, impact and tensile properties. 0G seamless steel tube is a kind of steel strip with hollow section and without seams. A steel pipe having a hollow cross section, used as a conduit for conveying fluids, such as pipelines for transporting petroleum, natural gas, gas, water, and certain solid materials.

- Q: What is a flange and how is it used in steel pipes?

- A flange is a mechanical device that is used to connect two sections of steel pipes together. It consists of a flat or raised ring that is attached to the end of each pipe section. The flange provides a surface for the pipes to be bolted or welded together, creating a secure and leak-proof joint. It also allows for easy disassembly and reassembly of the pipes when necessary. Flanges are commonly used in various industries, such as oil and gas, water treatment, and manufacturing, where the connection between steel pipes needs to be strong and reliable.

- Q: Are steel pipes resistant to earthquakes?

- Steel pipes are generally considered to be more resistant to earthquakes compared to other materials such as concrete or PVC pipes. This is due to the inherent properties of steel, which include its high tensile strength and flexibility. During an earthquake, steel pipes can absorb and distribute the seismic energy more effectively, allowing them to better withstand the shaking and ground movements. Additionally, steel pipes have the ability to deform without rupturing or collapsing, minimizing the risk of structural failure. However, it is important to note that the earthquake resistance of steel pipes ultimately depends on various factors such as the design, installation, and overall structural integrity of the piping system. Proper engineering and construction practices should be followed to ensure the highest level of earthquake resistance for steel pipes.

Send your message to us

Seamless HARD Carbon Steel Pipe&Tube For Tunnel And Anchor Rod 20# CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords