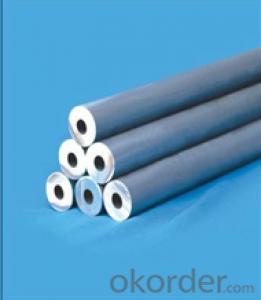

Seamless HARD Carbon Steel Pipe&Tube For Tunnel And Anchor Rod 10# CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1 - 14 mm | Section Shape: | Round | Outer Diameter: | 8 - 80 mm |

| Place of Origin: | HEB,HEB,HEB,China,FORM A,FORM E China (Mainland) Ch China (Mainland) | Secondary Or Not: | Non-secondary | Application: | Hydraulic Pipe |

| Technique: | Cold Rolled | Certification: | ISO9001:2008 | Surface Treatment: | oil |

| Special Pipe: | Thick Wall Pipe | Alloy Or Not: | Is Alloy | length: | 5-8m |

| usage3: | machine bush parts | usage4: | machine and engine pin | usage5: | tunnel and anchor rod |

| Test: | eddy current test,Ultrasonic Testing | usage2: | shock absorption bush | usage1: | power transmission machinery |

| colour: | black | name: | large-diameter hot-expanding seamless steel pipe | Grade: | 10#,20#,45#,16Mn,16Mo,16mo3,Q345,ST35,St37,ST37.4,St52,10#-45#,Mo,Q195-Q345,ST35-ST52 |

| Standard: | ANSI A210-1996,ASTM A1020-2002,ASTM A213-2001,ASTM A403-2007,ASTM A789-2001,BS 1387,BS EN10296,DIN 17175,DIN EN 10025,DIN EN 10217-1-2005,GB/T8162,GB/T8163,JIS G3459-2004,JIS G3461-2005,ASTM,BS,DIN,GB,JIS |

Packaging & Delivery

| Packaging Detail: | Marking: as per customer's requests. Painting varnish coating on the pipe. steel trips, woven bag |

| Delivery Detail: | 10-45 days or as the customer's request |

Seamless Carbon Hard Steel Pipe&Tube For Tunnel And Anchor Rod

Type | Manufacture & Sales OEM | |

Process | Seamless, Cold drawn and Cold rolled, finish-rolled | |

Material | 20#, 10#, 45#, 35# , Q345, 16Mn, 42CrMo | |

size | Outer Diameter | 8 –80mm |

Wall Thickness | 1-14mm | |

Length | 5-10m | |

Standard

| DIN st42, st45, st35, st37 and st52, GB 8162 | |

Package | 1. Bundle packing. 2. Bevelled end or plain end or warnished as per buyer's requestments. 3. Marking: as per customer's requests. 4. Painting varnish coating on the pipe. 5. Plastic caps at ends. | |

Delivery Time | 15to20 days or as clients reqestments | |

- Q: What are the different types of supports used for aboveground steel pipes?

- There are several types of supports commonly used for aboveground steel pipes, including pipe hangers, pipe clamps, pipe saddles, and pipe shoes. These supports are designed to provide stability and prevent excessive movement or vibration of the pipes, ensuring their proper alignment and preventing damage.

- Q: What are the properties of steel that make it suitable for pipe manufacturing?

- Steel is a highly preferred material for pipe manufacturing due to its unique properties. Firstly, steel exhibits exceptional strength and durability, making it capable of withstanding high pressure and extreme temperatures. This strength ensures that steel pipes can safely transport fluids and gases over long distances without the risk of leakage or breakage. Another important property of steel is its resistance to corrosion. Steel pipes are often exposed to various corrosive substances such as water, chemicals, and gases, which can degrade other materials over time. However, steel is highly resistant to corrosion, resulting in long-lasting and reliable pipes. Additionally, steel is a highly versatile material, allowing for various pipe sizes and shapes to be manufactured. Steel pipes can be customized to meet specific project requirements, making them suitable for a wide range of applications such as water supply, oil and gas transmission, sewage systems, and structural support. Moreover, steel is known for its excellent thermal conductivity, which is crucial for applications involving the transportation of hot or cold fluids. Steel pipes efficiently transfer heat, ensuring minimal energy loss during the process. Furthermore, steel is a recyclable material, making it an environmentally friendly option for pipe manufacturing. Steel pipes can be recycled and reused, reducing the need for new raw materials and minimizing waste generation. In conclusion, the properties of strength, durability, corrosion resistance, versatility, thermal conductivity, and recyclability make steel an ideal choice for pipe manufacturing. These properties ensure the reliability, efficiency, and longevity of steel pipes in various industries and applications.

- Q: What does "HBB" glass steel pipe mean?

- Non electrical corrosion, non-magnetic, suitable for single core cable laying, and steel pipe is a magnetic material, special treatment must be taken to prevent the formation of eddy currents.

- Q: How much is the wall thickness standard of building 48?

- Steel tube (Steel pipe) production technology development began in the bicycle manufacturing industry, the rise of the early nineteenth Century during the oil development, the two world war ships, boilers, aircraft manufacturing, manufacturing of power boiler after the Second World War, the development of chemical industry of petroleum and natural gas drilling and transportation, will effectively promote the the yield and quality of varieties, the development of steel tube industry.

- Q: What is the density of steel pipes?

- The density of steel pipes fluctuates based on the particular grade and composition of the steel employed. On the whole, steel pipes generally possess a density of approximately 7.8 grams per cubic centimeter (g/cm³) or 7800 kilograms per cubic meter (kg/m³). It should be emphasized that this figure may undergo slight variations contingent upon factors such as the manufacturing technique and the specific alloy integrated into the steel.

- Q: How are steel tubes represented?

- If you speak of steel pipe, if it is water. Gas transmission pipe, then it is said: nominal diameter refers to the inner diameter. The units are millimeters or inches. [for example, water pipes with phi 25. It means that the nominal diameter (diameter) is 25mm (or an inch) steel pipe.

- Q: What is the outer diameter and wall thickness of DN40 steel pipe?

- DN40 pipe diameter 48.3mm diameter, allowable deviation of plus or minus 0.5mm it depends on what you have, the outside diameter of 45, there are other dimensions, you can see the manual

- Q: How are steel pipes used in the construction of wind farms?

- Steel pipes are commonly used in the construction of wind farms to support and secure the wind turbines. These pipes serve as the foundation for the turbines, providing stability and structural integrity. They are used to create the tower structure, which supports the nacelle and rotor blades. Additionally, steel pipes are used for transporting and distributing the electrical cables within the wind farm, ensuring efficient transmission of electricity generated by the turbines.

- Q: Is the steel frame on each floor supporting formwork (floor) called full scaffolding?

- The scaffold is also called full house scaffolding is a construction process for building a scaffold. Hall scaffolding relative to other scaffolding system density, that is, the house full of shelves. The full scaffolding is more secure than the rest of the scaffolding.

- Q: Can steel pipes be used for conveying liquids and gases?

- Yes, steel pipes can be used for conveying both liquids and gases. Steel pipes are commonly used in various industries, including oil and gas, water supply, plumbing, and industrial processes, due to their strength, durability, and resistance to corrosion. They are capable of withstanding high pressure and temperature, making them suitable for transporting a wide range of liquids and gases such as water, oil, natural gas, steam, and chemicals. Additionally, steel pipes can be welded or threaded together, allowing for easy installation and maintenance.

Send your message to us

Seamless HARD Carbon Steel Pipe&Tube For Tunnel And Anchor Rod 10# CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords