Seamless Carbon And Alloy Steel Tubing good sell

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1、Structure of Seamless Carbon And Alloy Steel Tubing good sell:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of Seamless Carbon And Alloy Steel Tubing good sell:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless Carbon And Alloy Steel Tubing good sell Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

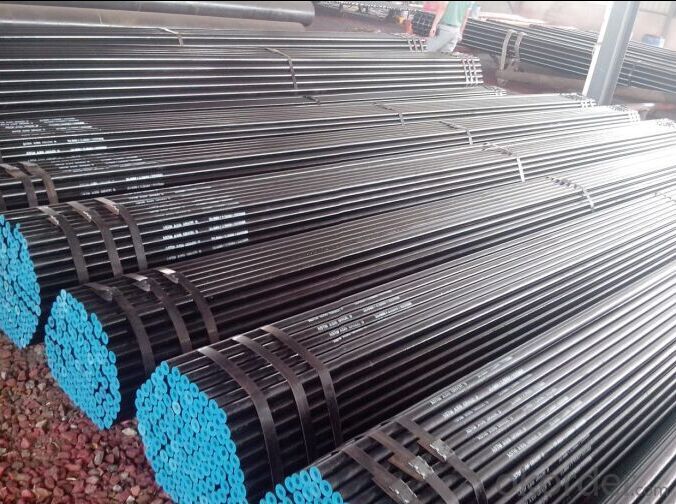

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Carbon And Alloy Steel Tubing good sell:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

6、Seamless Carbon And Alloy Steel Tubing good sell Images:

- Q: What are the different types of steel pipe coatings for nuclear power plants?

- There are several different types of steel pipe coatings used in nuclear power plants. These include epoxy coatings, fusion bond epoxy (FBE) coatings, polyethylene (PE) coatings, and coal tar enamel (CTE) coatings. Each coating has its own specific properties and advantages, such as corrosion resistance, chemical resistance, and abrasion resistance, to ensure the durability and longevity of the steel pipes in the demanding nuclear power plant environment.

- Q: Are steel pipes suitable for semiconductor manufacturing plants?

- Yes, steel pipes are suitable for semiconductor manufacturing plants. Steel pipes offer several advantages such as high strength, durability, and resistance to corrosion, making them ideal for transporting various fluids and gases used in semiconductor manufacturing processes. Additionally, steel pipes can withstand high pressure and extreme temperatures, ensuring the safe and efficient operation of semiconductor manufacturing plants.

- Q: What is DN50 for welded pipe?

- Commonly used in the market DN50 seamless steel pipe, the outer diameter has two specifications: A, 57mm, B, 60mm, if no special instructions, commonly used is 57mm. The outer diameter of the welded pipe is only 60mm this specification.

- Q: Can steel pipes be used for pharmaceutical manufacturing plants?

- Yes, steel pipes can be used for pharmaceutical manufacturing plants. Steel pipes are commonly used in pharmaceutical manufacturing plants for various purposes such as conveying fluids, gases, and chemicals within the facility. They are preferred due to their durability, strength, and resistance to corrosion, making them suitable for maintaining the integrity and purity of pharmaceutical products. Additionally, steel pipes can be easily cleaned and sterilized, meeting the stringent hygiene and safety requirements of pharmaceutical manufacturing.

- Q: Can steel pipes be used for pharmaceutical manufacturing?

- Yes, steel pipes can be used for pharmaceutical manufacturing. Steel pipes are commonly used in various industries, including pharmaceutical manufacturing, due to their durability, strength, and resistance to corrosion. In pharmaceutical manufacturing, steel pipes are primarily used for fluid transportation, such as the transfer of chemicals, solvents, and other raw materials. They are also used for the distribution of process water, steam, and other utilities. Stainless steel pipes are particularly preferred in pharmaceutical manufacturing as they are highly resistant to corrosion and can withstand high temperatures and pressures. Moreover, stainless steel pipes have smooth surfaces, which prevent the accumulation of particles and facilitate easy cleaning and sterilization, essential requirements in pharmaceutical production. Overall, steel pipes are a reliable and suitable option for pharmaceutical manufacturing due to their robustness, resistance to corrosion, and ability to meet the stringent cleanliness and hygiene standards of the industry.

- Q: Are steel pipes suitable for use in food processing industries?

- Yes, steel pipes are suitable for use in food processing industries. Steel pipes are known for their durability, strength, and resistance to corrosion, making them ideal for handling food products. They are also easy to clean and maintain, ensuring proper hygiene standards in the food processing industry. Additionally, steel pipes are capable of withstanding high temperatures and pressures, making them suitable for various food processing applications such as transporting liquids, gases, and solids.

- Q: Can steel pipes be painted?

- Yes, steel pipes can be painted. Painting steel pipes provides protection against corrosion, enhances their aesthetic appearance, and can help them blend with the surrounding environment. Prior to painting, the pipes need to be cleaned, primed, and then coated with a suitable paint designed for metal surfaces.

- Q: How do you repair a damaged steel pipe?

- To repair a damaged steel pipe, you can follow a few steps. First, identify the extent of the damage, such as cracks or holes. Next, clean the damaged area using a wire brush or sandpaper to remove any rust, debris, or old paint. Then, apply a suitable epoxy or sealing compound to seal the crack or hole. For larger damages, welding or brazing may be necessary. Finally, ensure the repaired area is dry and properly cured before testing the pipe for leaks or further issues.

- Q: How are steel pipes used in the manufacturing of geothermal systems?

- Steel pipes are used in the manufacturing of geothermal systems primarily for their strength, durability, and resistance to corrosion. These pipes are used to transport fluid, typically water or a water-based solution, from the geothermal source to the surface, where it can be utilized for heating or electricity generation. The high tensile strength of steel pipes allows them to withstand the high pressure and temperature conditions typically found in geothermal systems. Additionally, steel pipes are resistant to corrosion, which is important in preventing leaks and maintaining the efficiency of the system over its lifespan.

- Q: What are the different methods of heat treatment for steel pipes?

- Some of the different methods of heat treatment for steel pipes include annealing, quenching, tempering, normalizing, and stress relieving.

Send your message to us

Seamless Carbon And Alloy Steel Tubing good sell

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords